Method for preparing iron-cobalt bimetallic monatomic anchored nitrogen-doped graphene cocatalyst and application thereof

A cocatalyst and bimetallic technology, which is applied in the field of preparing iron-cobalt bimetallic single-atom-anchored azagraphene cocatalysts, can solve the problems of lack of platinum group metal reserves, high cost, and restricting the industrial application of platinum group metals, etc. Effects of fast photogenerated electron-hole separation and transport efficiency, low cost, and excellent photocatalytic hydrogen production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

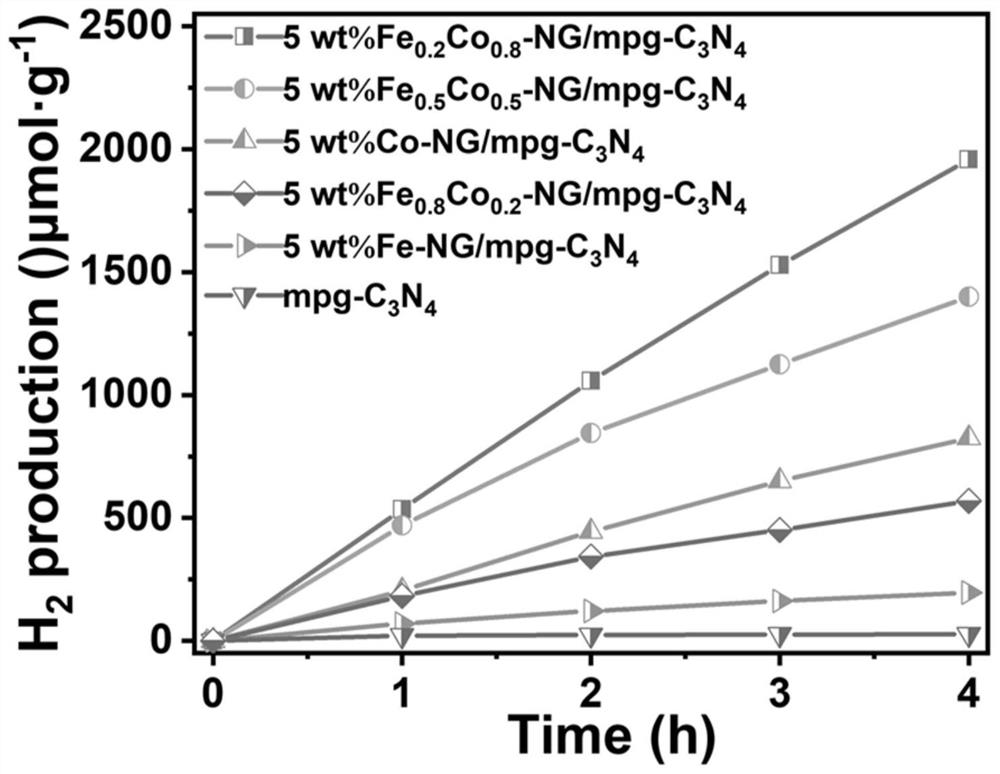

[0023] Step 1, weigh 100 mg of graphene oxide and add it to 50 mL of deionized water, mix evenly by ultrasonic, add dropwise 0.8 mL of 3 mg / mL cobalt chloride aqueous solution and 0.2 mL of 3 mg / mL ferric chloride aqueous solution, and ultrasonically make it in Uniformly disperse in the mixed solution to obtain solution A (the volume ratio of cobalt chloride aqueous solution and ferric chloride aqueous solution is 4:1);

[0024] Step 2, after the solution A was quickly frozen with liquid nitrogen, freeze-drying was performed for 48 h;

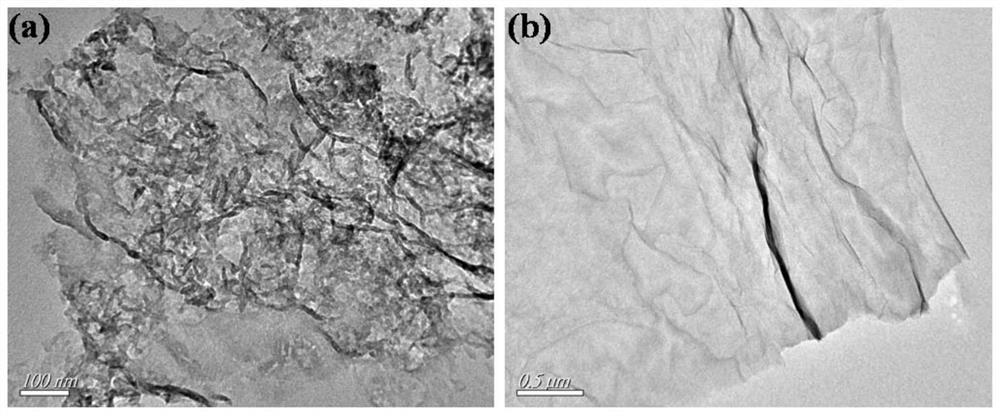

[0025] Step 3, put the sample into an atmosphere of ammonia and argon for calcination at 750 °C for 1 h, the flow rate of argon gas is 170 mL / min, the flow rate of ammonia gas is 70 mL / min, and the heating rate is 12 °C / min, to obtain iron Cobalt bimetallic single-atom-anchored azagraphene, denoted as Fe 0.2 co 0.8 -NG spare;

[0026] Step 4, weigh 5 mg Fe 0.2 co 0.8 -NG, added to 30 mL absolute ethanol, sonicated evenly, added 100 mgmpg-C...

Embodiment 2

[0028] Step 1, weigh 100 mg of graphene oxide and add it to 50 mL of deionized water, and mix evenly by ultrasonic, add dropwise 0.5 mL of 3 mg / mL cobalt chloride aqueous solution and 0.5 mL of 3 mg / mL ferric chloride aqueous solution, and ultrasonically mix Uniformly disperse in the solution to obtain solution A (the volume ratio of cobalt chloride aqueous solution and ferric chloride aqueous solution is 1:1);

[0029] Step 2, after the solution A was quickly frozen with liquid nitrogen, freeze-drying was performed for 48 h;

[0030] Step 3, put the sample into an atmosphere of ammonia and argon for calcination at 750 °C for 1 h, the flow rate of argon gas is 170 mL / min, the flow rate of ammonia gas is 70 mL / min, and the heating rate is 12 °C / min, to obtain iron Cobalt bimetallic single-atom-anchored azagraphene, denoted as Fe 0.5 co 0.5 -NG spare;

[0031] Step 4, weigh 5 mg Fe 0.5 co 0.5 -NG, added to 30 mL absolute ethanol, sonicated evenly, added 100 mgmpg-C 3 N 4 ...

Embodiment 3

[0033] Step 1, weigh 100 mg of graphene oxide and add it to 50 mL of deionized water, ultrasonically mix evenly, add dropwise 0.2 mL of 3 mg / mL cobalt chloride aqueous solution and 0.8 mL of 3 mg / mL ferric chloride aqueous solution, and ultrasonically make it in Uniformly disperse in the mixed solution to obtain solution A (the volume ratio of cobalt chloride aqueous solution and ferric chloride aqueous solution is 1:4);

[0034] Step 2, after the solution A was quickly frozen with liquid nitrogen, freeze-drying was performed for 48 h;

[0035] Step 3, put the sample into an atmosphere of ammonia and argon for calcination at 750 °C for 1 h, the flow rate of argon gas is 170 mL / min, the flow rate of ammonia gas is 70 mL / min, and the heating rate is 12 °C / min, to obtain iron Cobalt bimetallic single-atom-anchored azagraphene, denoted as Fe 0.8 co 0.2 -NG spare;

[0036] Step 4, weigh 5 mg Fe 0.8 co 0.2 -NG, added to 30 mL absolute ethanol, sonicated evenly, added 100 mgmpg-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com