Heterogeneous conductor of submarine cable, processing method of heteroconductor, submarine cable and preparation method of submarine cable

A technology of submarine cables and processing methods, which is applied in the directions of submarine cables, conductors, insulated conductors, etc., can solve problems such as poor welding quality, and achieve the effect of improving welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] In yet another typical embodiment of the present application, a preparation method of the above-mentioned submarine cable is provided, the preparation method includes sequentially performing conductor shielding layer recovery, insulation layer recovery, insulation shielding layer recovery, The recovery of the metal shielding layer and the recovery of the non-metallic sheath layer, wherein the recovery of the insulating layer includes: performing stress cone peeling, extrusion molding, and vulcanization of the insulating layer in sequence. When the submarine cable heterogeneous conductor of the present application is used as the submarine cable conductor, it can be prepared by the conventional preparation method of the submarine cable, which expands the industrial applicability of the submarine cable heterogeneous conductor of the present application.

[0057] In some embodiments, the vulcanization described above is performed in a vulcanization mold with an induction coi...

Embodiment 1

[0061] The first step, cleaning (first conductor 1) copper monofilament and (fourth conductor 4) aluminum monofilament:

[0062] For copper power cable core a and aluminum power cable core b (the radial cross-sectional areas of copper power cable core a and aluminum power cable core b are equal and less than 120mm 2 ) after alignment pretreatment, place it on a special support, and use alcohol wipe and air shower to clean the surface before operation. After cleaning, the two power cores are dissected according to the predetermined size, and the layers are arranged in a T-shape from the outside to the inside, and the order is: non-metallic sheath layer, metal shielding layer, insulating shielding layer, insulating layer, conductor shielding layer, conductor, Among them, the insulating layer is longer than other component layers (stress cone peeling is required). After the stripping of each layer structure, the surface cleaning is carried out again:

[0063] The surface treatm...

Embodiment 2

[0095] The difference between embodiment 2 and embodiment 1 is that

[0096] In the first step, the radial cross-sectional areas of copper power cable core a and aluminum power cable core b are equal and greater than 120mm 2 .

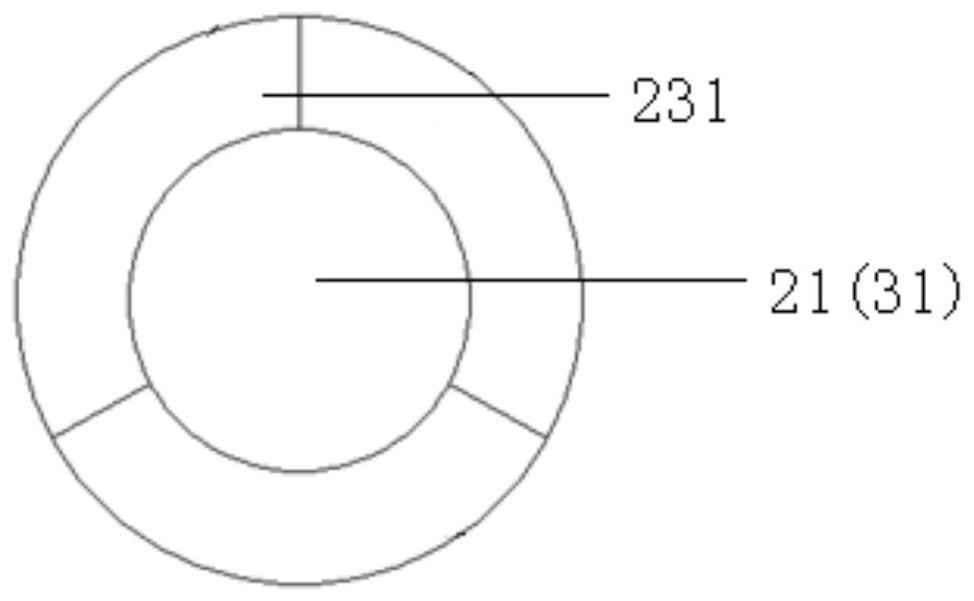

[0097] In the second step, a cylindrical copper conductor (second conductor core 21 ) and an aluminum conductor (third conductor core 31 ) with a length of 15 mm and equal radial cross-sectional areas are respectively taken.

[0098] Form the first welding layer on the second conductor core 21 by friction welding three first circular welding segments to obtain the second conductor 2, one end of the first welding layer is flush with one end of the second conductor core 21, the first The other end of the welding layer protrudes from the second conductor core 21 by 15 mm, and the radial cross-sectional area of the second conductor 2 is equal to that of the copper power cable core a.

[0099] Form the second welding layer on the third conductor core 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com