Method for detecting binding force of DPC ceramic copper-plated substrate

A detection method and technology of binding force, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of flow to the client, misjudgment, uneven temperature of products, etc. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

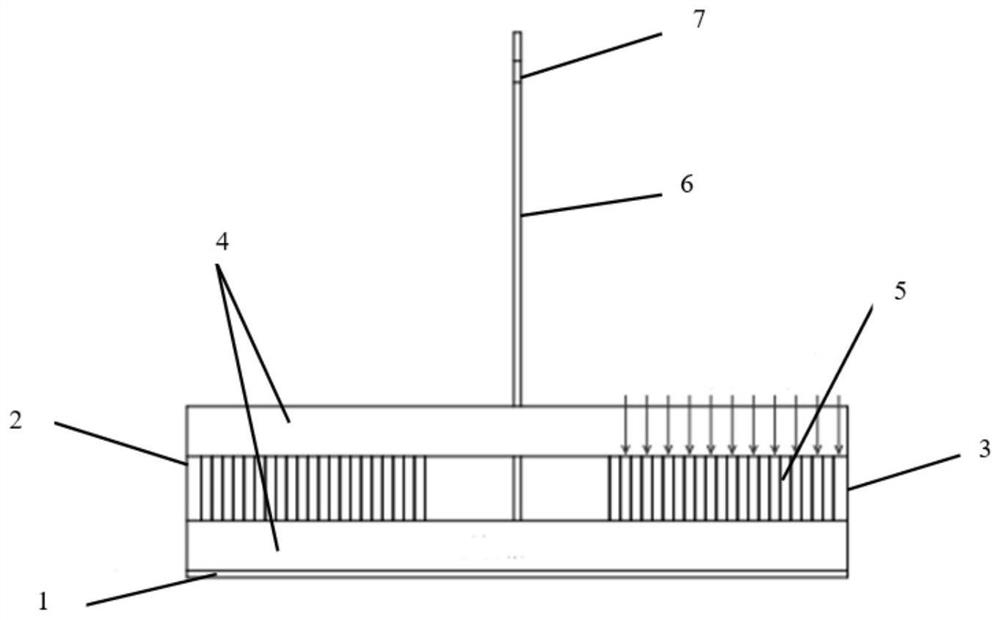

Image

Examples

Embodiment 1

[0041] S1. Prepare the baking jig

[0042] 1). Preparation of polybenzimidazole solution

[0043] a. Add 200g of polyphosphoric acid and 4g of 3,3',4,4'-tetraaminodiphenyl ether into the reaction vessel, pass through nitrogen protection, heat the oil bath to 160°C, and keep it warm for 12 hours. Stir continuously at a rate;

[0044] b. After the heat preservation is completed, the temperature is raised to 220° C., and 7 g of phosphorus pentoxide and 3.5 g of terephthalic acid are continuously added to the reaction vessel, and after 12 hours of reaction, a polymer is obtained;

[0045] c. Pour the polymer into ammonia water and soak for 24 hours, filter, wash with deionized water, place it in a vacuum dryer, and dry it in vacuum at 100°C. After drying, the polybenzimidazole polymer can be obtained;

[0046] d. Weigh 100g of the prepared polybenzimidazole polymer, add it into 1500g dimethyl sulfoxide, and stir until dissolved to obtain the polybenzimidazole solution;

[0047]...

Embodiment 2

[0055] S1. Prepare the baking jig

[0056] 1). Preparation of polybenzimidazole solution

[0057] a. Add 200g of polyphosphoric acid and 4g of 3,3',4,4'-tetraaminobiphenyl into the reaction vessel, pass through nitrogen protection, heat the oil bath to 160°C, and keep it warm for 12 hours. Stir continuously at a rate;

[0058] b. After the heat preservation is over, raise the temperature to 220°C, continue to add 7g of phosphorus pentoxide and 3.5g of 4,4'-dicarboxydiphenylsulfone into the reaction vessel, and react for 12 hours to obtain a polymer;

[0059] c. Pour the polymer into a sodium hydroxide solution with a pH value of 8 and soak for 24 hours, filter it, wash it with deionized water, put it in a vacuum dryer, and dry it in a vacuum at 100 ° C. After drying, it can be Obtain polybenzimidazole polymer;

[0060] d. Weigh 100g of the prepared polybenzimidazole polymer, add it into 1500g dimethyl sulfoxide, and stir until dissolved to obtain the polybenzimidazole solut...

Embodiment 3

[0069] S1. Prepare the baking jig

[0070] 1). Preparation of polybenzimidazole solution

[0071] a. Add 200g of polyphosphoric acid and 4g of 3,3',4,4'-tetraaminodiphenyl sulfide into the reaction vessel, pass through nitrogen protection, heat the oil bath to 120°C, and keep it warm for 48 hours. Stirring at a rate of 60rpm;

[0072] b. After the heat preservation is completed, heat up to 200°C, continue to add 7g of phosphorus pentoxide and 3.5g of 4,4'-dicarboxydiphenylsulfone into the reaction vessel, and react for 24 hours to obtain a polymer;

[0073] c. Pour the polymer into a sodium hydroxide solution with a pH value of 8 and soak for 24 hours, filter it, wash it with deionized water, put it in a vacuum dryer, and dry it in a vacuum at 100 ° C. After drying, it can be Obtain polybenzimidazole polymer;

[0074] d. Weigh 100g of the prepared polybenzimidazole polymer, add it into 1500g dimethyl sulfoxide, and stir until dissolved to obtain the polybenzimidazole soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com