Silver-plated conductive fabric and preparation method and application thereof

A technology of conductive fabrics and fabrics, which can be used in textiles, papermaking, plant fibers, electrical components, etc., and can solve problems such as poor washing resistance and weak binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In the present invention, the method of preparing the mercapto-modified fabric preferably comprises the step of modifying the fabric using a mercapto compound to obtain a mercapto-modified fabric.

[0035] In the present invention, the fabric is preferably carried out before use; the detergent is preferably a methanol washing and washing, and the alcohol washing alcohol preferably includes ethanol and / or methanol; the washing is preferably carried out under ultrasound conditions. The present invention is not particularly limited to the conditions of the ultrasonic washing, and dust and grease contaminants on the surface of the fabric can be removed. In the present invention, the activation is preferably acid activated and / or alkali activation; the acid activated acid is preferably a hydrochloric acid solution, and the concentration of the hydrochloric acid solution is preferably from 0.1 to 1 mol / L, more preferably 0.5 to 0.8 mol. / L; The present invention is not par...

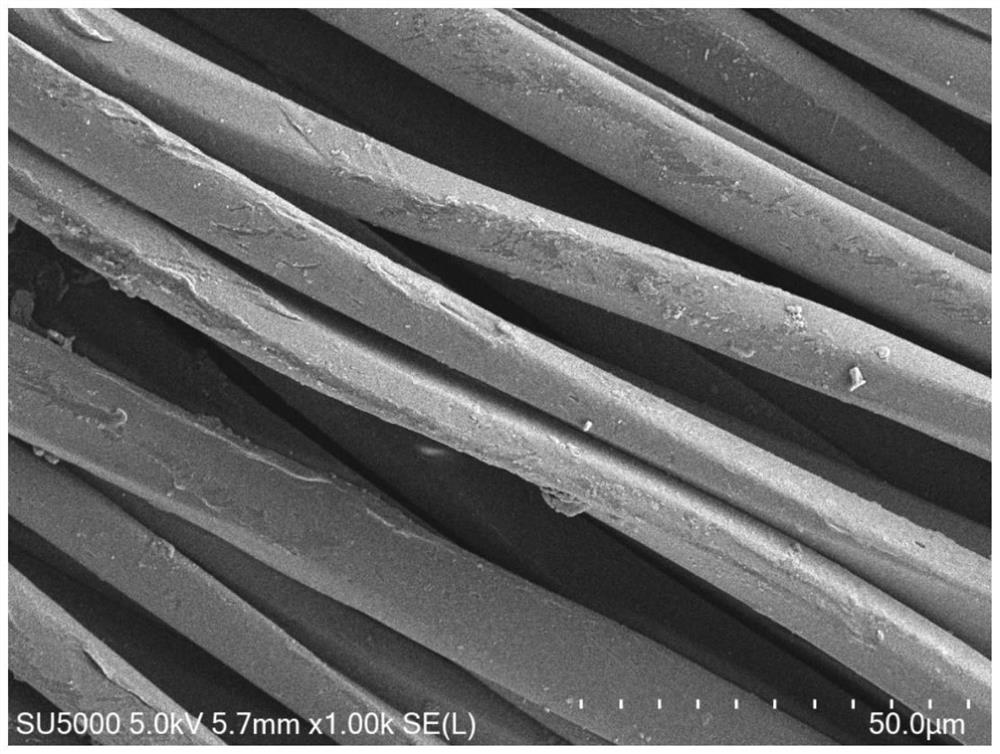

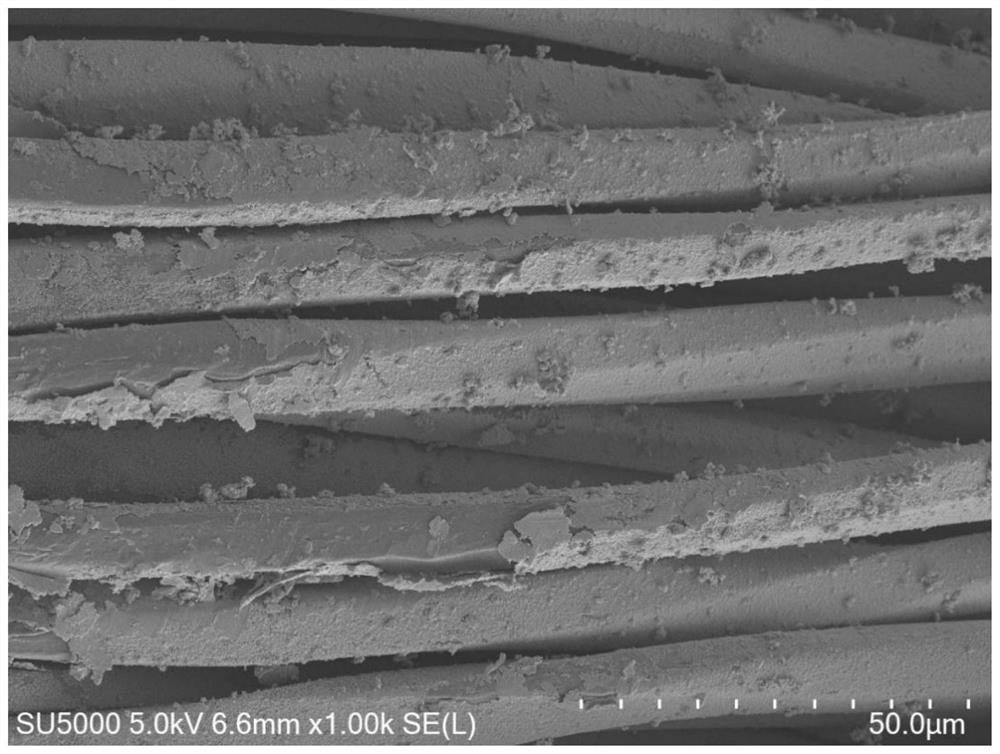

Embodiment 1

[0056] (1) The polyester fabric (3 cm × 3 cm) was sequentially washed with ethanol, and the aqueous ultrasound washing, the NaOH aqueous solution of 30 g / L was treated under 70 ° C, and then the water was washed into a neutral dry to constant weight, resulting activation The fabric is placed in a 3-mercaptopyltrimethoxysilane solution placed at a 10 ml concentration of 0.05 mol / L, and is modified at 100 ° C for 60 min to obtain a mercapto-modified fabric.

[0057] (2) 0.0006 mol Glucose, 0.0002 mol tarttic acid and 0.0001 mol cysteine were dissolved in 10 ml of water, and mixed with 2 ml of stabilizer ethanol and mixed, resulting in a composite reducing agent solution.

[0058] (3) Place the mercapto-modified fabric in a silver ammonia solution having a concentration of 0.15 mol / L, and the composite reducing agent solution obtained by the step (2) is mixed, and the reducing reaction is reduced at 30 ° C - a complexation reaction at a mercaptogen change The surface of the f...

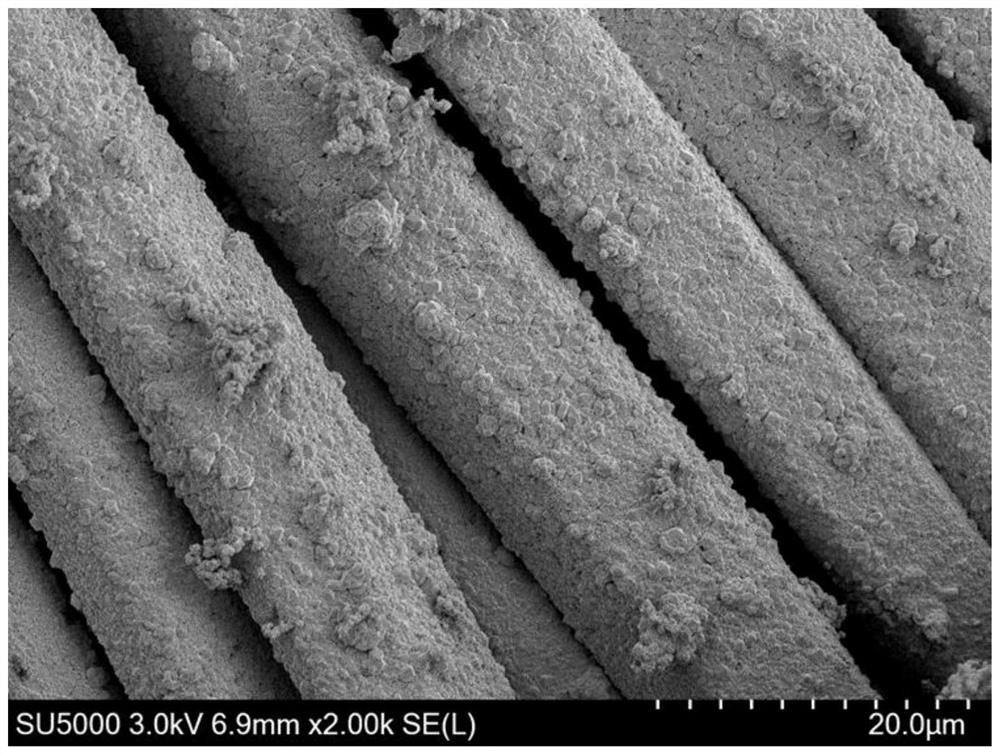

Embodiment 2

[0061] (1) The polyester fabric (3 cm × 3 cm) was sequentially washed with ethanol, and the aqueous ultrasound washed, the NaOH aqueous concentration of 30 g / L was administered under 60 ° C for 1.5 h, and then the water was washed into a neutral dry to constant weight, obtained Active fabric; a 3-mercapto-propylenezoxy silicone solution placed in a 10 ml concentration of 0.5 mol / L, modified at 100 ° C for 60 min to obtain a mercapto-modified fabric.

[0062] (2) 0.002 mol glucose, 0.0004 mol maldose and 0.0004 mol cysteine were dissolved in 20 ml of water, and the mixture was mixed with 4 ml of stabilizer ethanol to give a composite reducing agent solution.

[0063] (3) Place the mercapto-modified fabric in a silver ammonia solution having a concentration of 0.2 mol / L, and the composite reducing agent solution obtained by the step (2) is mixed, and the complexation reaction is reduced at 35 ° C for 60min in thiol modification. Silver layer is formed on the surface of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com