A kind of three-dimensional carbon-rich nanofiber ceramic airgel and its preparation method

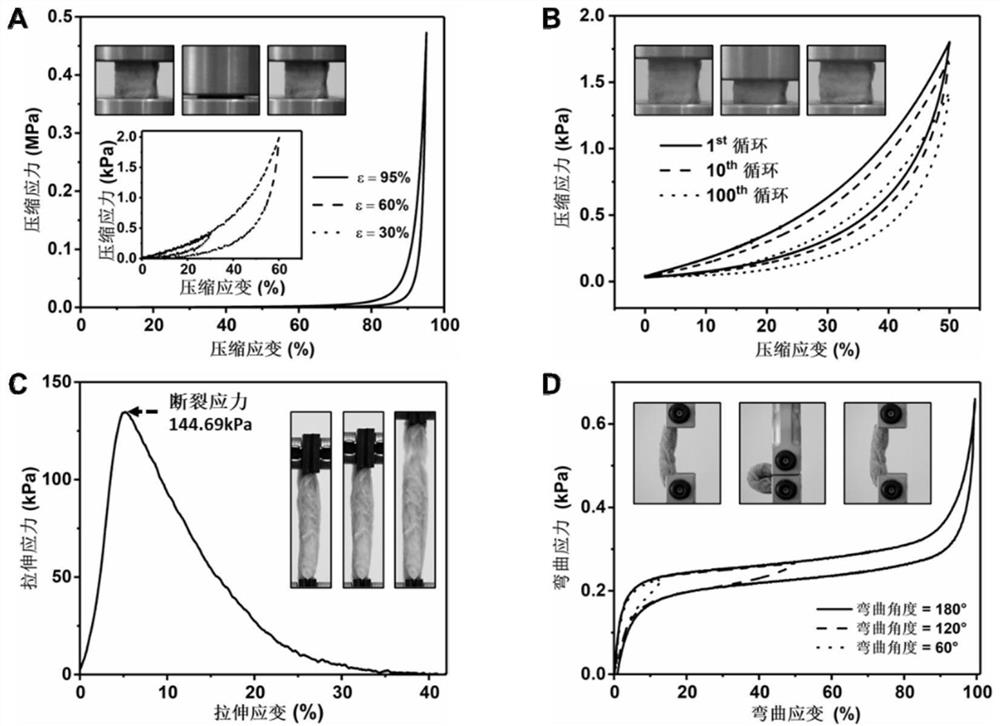

A nanofiber and aerogel technology, which is applied in the field of three-dimensional carbon-rich nanofiber ceramic aerogel and its preparation, can solve problems such as deficiencies, achieve excellent mechanical properties, low production cost, and excellent compressible rebound and anti-fatigue characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

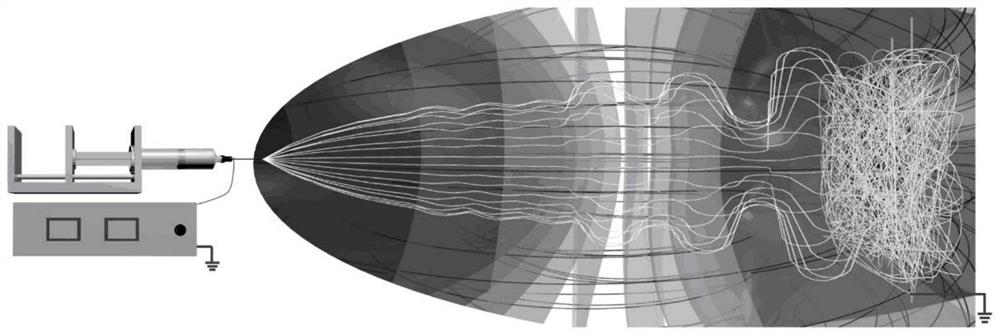

[0023] The invention is based on the principle of preparing nanofibers by electrospinning method, by controlling the distance between an electrospinning needle and a collector, and using the directional weakening electric field force generated by a far electric field to prepare and shape a three-dimensional carbon-rich nanofiber ceramic airgel. The specific device mainly includes the following parts: high-voltage DC power supply, intelligent injection pumping controller, electrospinning precursor injection device, and sparse metal mesh collection device; among them, the intelligent injection pumping controller mainly regulates the stepping injection flow rate of the injection device The electrospinning precursor injection device pushes the precursor solution into the electrospinning needle; the high-voltage DC power supply mainly provides the high-voltage DC electrostatic field for electrospinning; the sparse metal mesh collection device is mainly used to collect and form the th...

Embodiment 2

[0030] A preparation method of a three-dimensional carbon-rich nanofiber ceramic airgel, as follows:

[0031] 1) Under the temperature condition of 40℃~60℃, fully dissolve and mix the methanol solution of polyzirconium acetylacetonate and yttrium nitrate hexahydrate with the methanol solution of silane coupling agent KH550, and then add the high molecular weight polyethylene oxide PEO The methanol solution is fully co-dissolved to obtain a highly spinnable binary silicon-zirconium ceramic electrospinning precursor solution; wherein, the raw material formula is as follows according to the mass ratio: polyzirconium acetylacetonate: yttrium nitrate hexahydrate: silane coupling Agent KH550: high molecular weight polyethylene oxide PEO: methanol = 50:20:83:0.4:350.

[0032] 2) Take the above 35ml highly spinnable binary silicon-zirconium ceramic electrospinning precursor, stably control the temperature at room temperature 26°C, humidity conditions at 50%, and the distance between t...

Embodiment 3

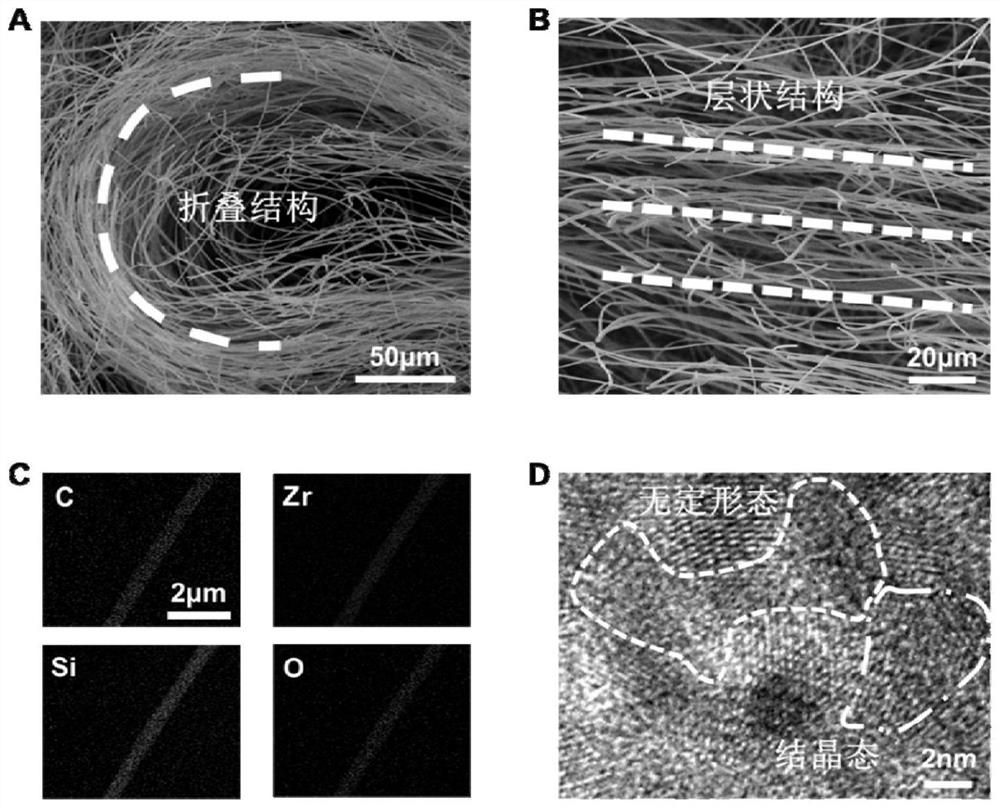

[0036] to combine figure 2 , The structural characterization test photos of the three-dimensional carbon-rich nanofiber ceramic airgel prepared by far electric field-electrospinning are as follows:

[0037] The present invention proposes to prepare three-dimensional carbon-rich nanofiber ceramic airgel through the method of far electric field-electrospinning, and control the distance between the electrospinning needle and the collector to keep 0.5m to 0.7m, and the current precursor is at the electrospinning needle When being pushed out, the droplet first forms a Taylor cone under the combined action of the high-voltage electrostatic field force and the surface tension of the liquid. When the charge repulsion on the droplet under the action of the electric field is greater than the surface tension of the liquid, a scattering jet is formed at the tail of the Taylor cone. At the same time, it moves along a complex trajectory in the far electric field and entangles with each oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com