Optical fiber ribbon optical cable

An optical fiber ribbon and cable technology, which is applied in the field of optical fiber communication, can solve the problems of increased core density, high cost, and reduced effective utilization product, and achieves the effect of high core density, less material consumption, and small product diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

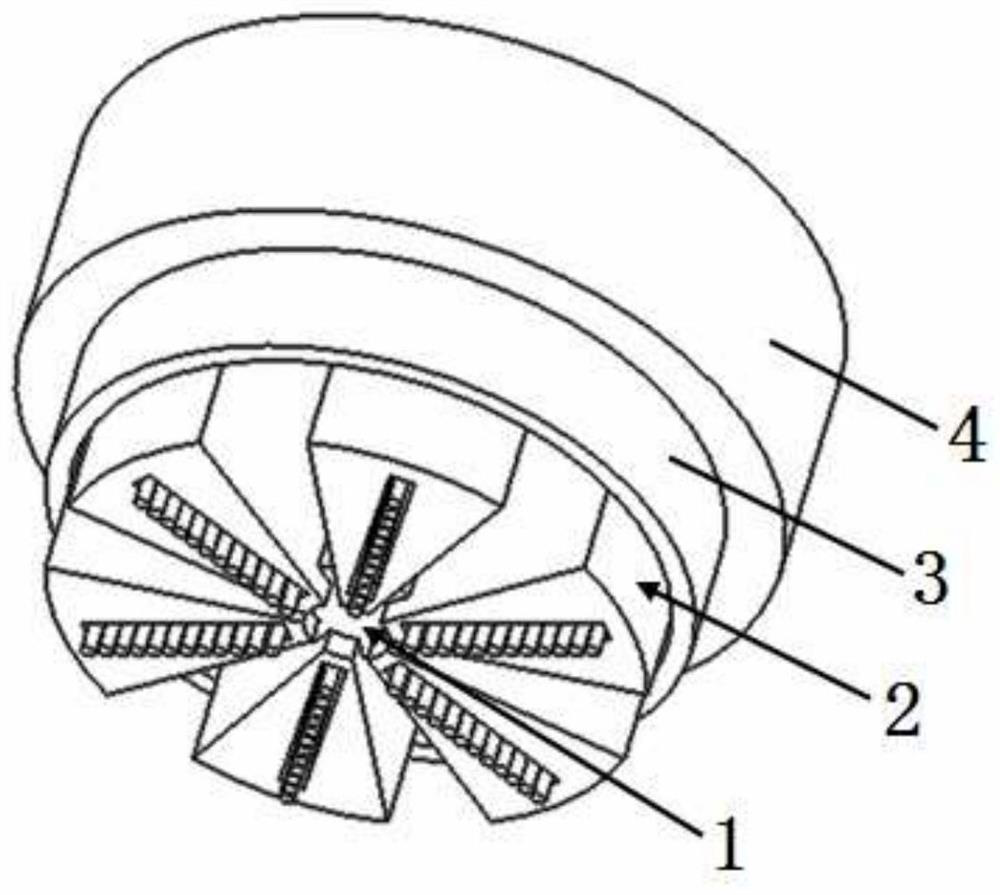

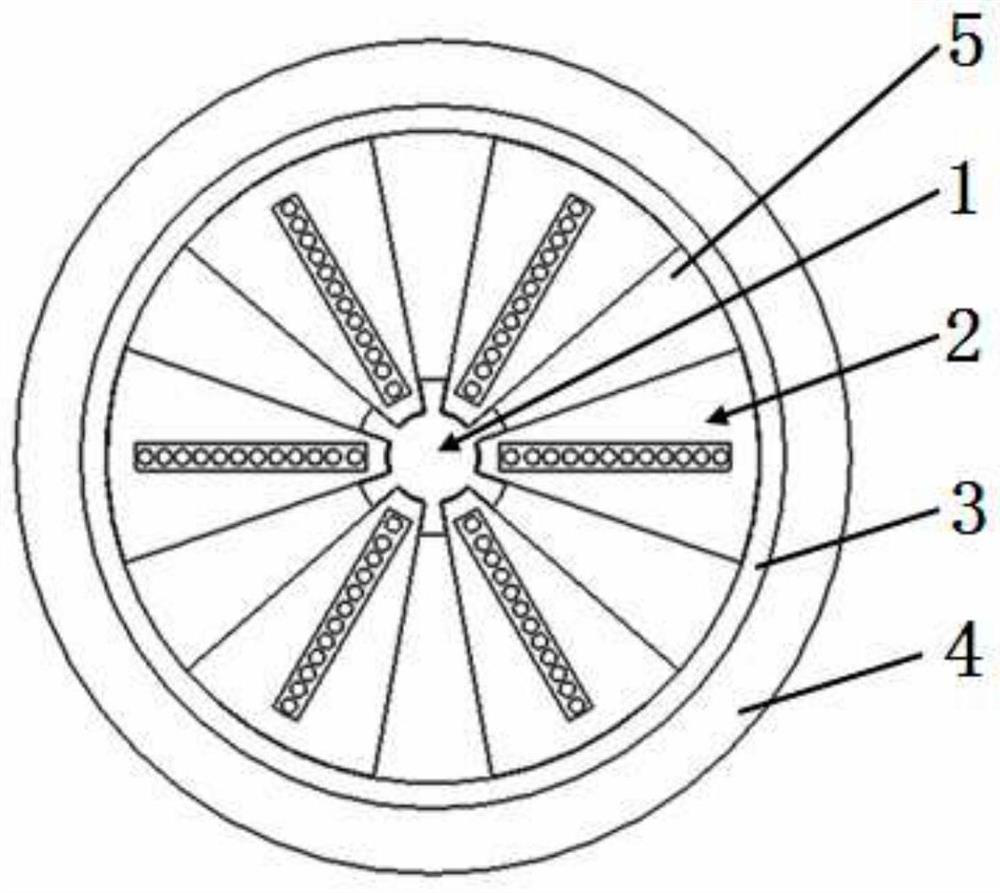

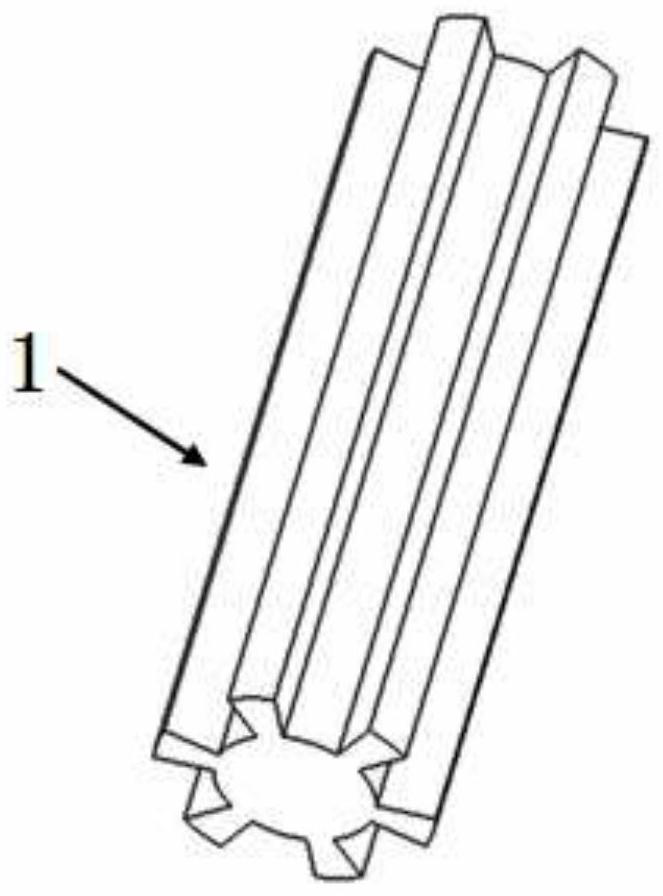

[0057] please see Figure 1 to Figure 6 , an optical fiber ribbon cable, has a skeleton part 1, a plurality of loose sleeve parts 2, a protective layer 3, and an outer sheath 4, and is characterized in that: the skeleton part 1 is composed of a skeleton body 11 and distributed outside the skeleton body 11 Consisting of a plurality of bone leaves 12, there are recessed skeleton grooves 13 between adjacent bone leaves 12, the skeleton parts are of an integrated structure, and the outer edges of all bone leaves 12 are on the same circumference; the cross section of the loose sleeve part 2 The loose tube part 2 is composed of a loose tube 21. The upper and lower sides of the loose tube 21 have a rectangular tube main cavity 23 near the center, and the main optical fiber ribbon 22 is located in the tube main cavity 23. , the length of the main cavity of the sleeve is much greater than the width, and the upper and lower symmetrical axes of the main cavity of the sleeve coincide with...

Embodiment 2

[0059] please see Figure 7 to Figure 9 ,refer to Figure 1 to Figure 6 , an optical fiber ribbon cable, has a skeleton part 1, a plurality of loose sleeve parts 2, a protective layer 3, and an outer sheath 4, and is characterized in that: the skeleton part 1 is composed of a skeleton body 11 and distributed outside the skeleton body 11 Consisting of a plurality of bone leaves 12, there are recessed skeleton grooves 13 between adjacent bone leaves 12, the skeleton parts are of an integrated structure, and the outer edges of all bone leaves 12 are on the same circumference; the cross section of the loose sleeve part 2 The loose tube part 2 is composed of a loose tube 21. The upper and lower sides of the loose tube 21 have a rectangular tube main cavity 23 near the center, and the main optical fiber ribbon 22 is located in the tube main cavity 23. , the length of the main cavity of the sleeve is much greater than the width, and the upper and lower symmetrical axes of the main c...

Embodiment 3

[0061] please see Figure 10 to Figure 13 ,refer to Figure 1 to Figure 9 , an optical fiber ribbon cable, has a skeleton part 1, a plurality of loose sleeve parts 2, a protective layer 3, and an outer sheath 4, and is characterized in that: the skeleton part 1 is composed of a skeleton body 11 and distributed outside the skeleton body 11 Consisting of a plurality of bone leaves 12, there are recessed skeleton grooves 13 between adjacent bone leaves 12, and the skeleton parts are of an integrated structure, and the outer edges of all bone leaves 12 are on the same circumference; the loose sleeve part 2 consists of a loose sleeve 21 , an upper limit part 24, and a lower limit part 25. The cross section of the loose tube 21 is fan-shaped with the top angle removed, and there is a rectangular casing main cavity 23 near the center of the upper and lower sides of the loose tube 21. The main optical fiber ribbon 22 is located in the casing main cavity 23, the length of the casing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com