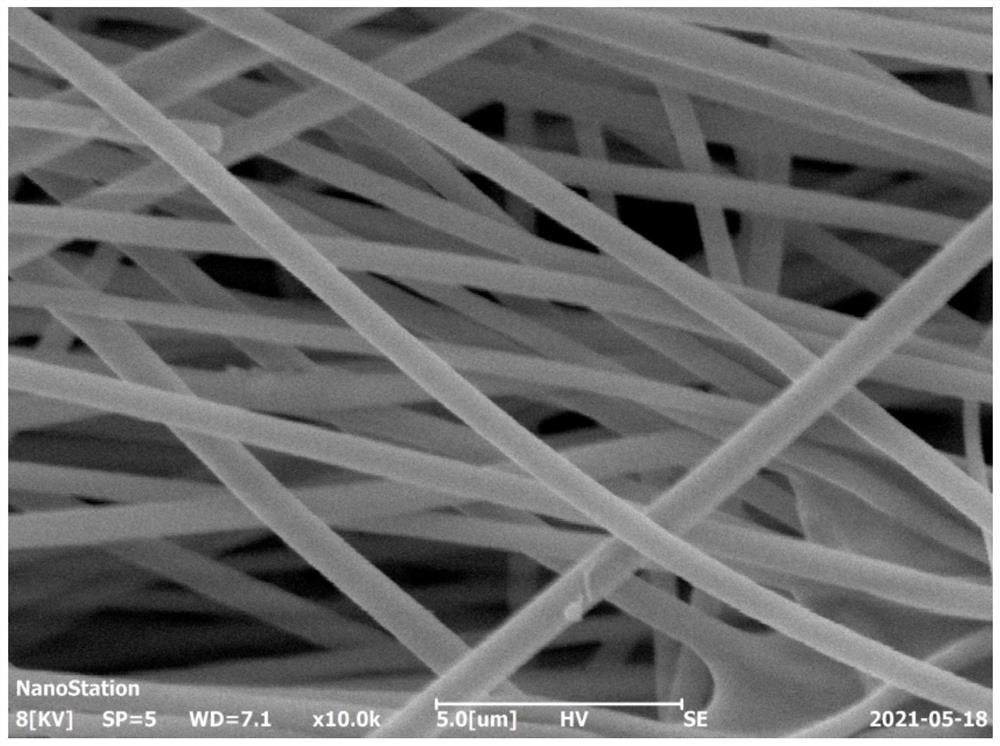

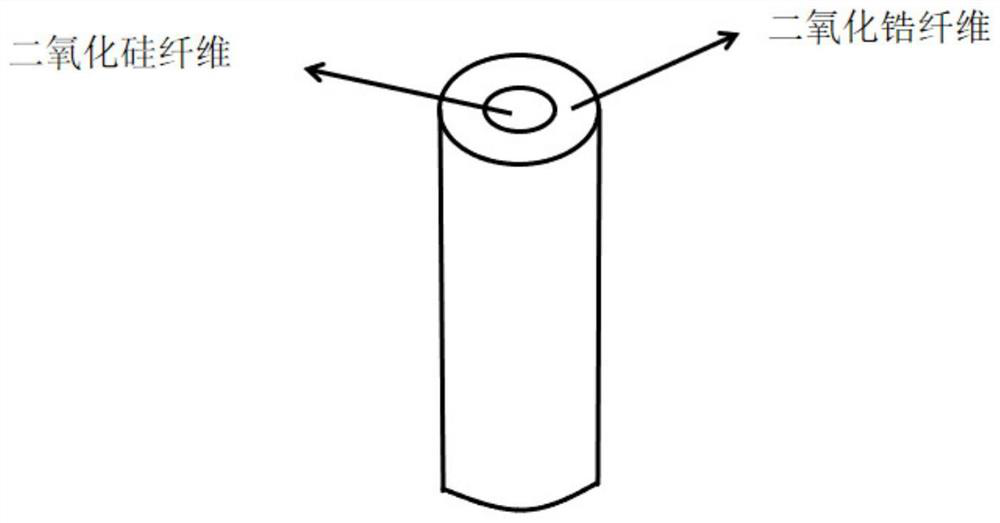

Preparation method of flexible composite nanofiber membrane with core-shell structure

A technology of composite nanofibers and shell structures, which is applied in the chemical characteristics of fibers, rayon manufacturing, and conjugated synthetic polymer rayon filaments, etc., can solve problems such as cumbersome steps, achieve good high temperature resistance, and reduce end effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the flexible composite nanofiber membrane of the core-shell structure of the present invention comprises:

[0033] In step 101, ethyl orthosilicate, pure water, absolute ethanol and anhydrous acetic acid are mixed and stirred until clear to obtain a silicon source solution. Wherein, anhydrous acetic acid is used as hydrolysis reaction catalyst.

[0034] Specifically, in one embodiment, tetraethyl orthosilicate, pure water, absolute ethanol, and anhydrous acetic acid are placed in a conical flask in a molar ratio of 1:0.6:0.6:0.01 for sealed mixing. Stir at 45°C for 4-6h to obtain a clear silicon source solution.

[0035] Among them, the molecular weight of ethyl orthosilicate is 208.33.

[0036] Step 102, dissolving the high molecular polymer in a solvent to prepare a high molecular polymer solution.

[0037] In one embodiment, the high molecular polymer is dissolved in a solvent at a mass concentration of 10%-20%, and stirred in a water bat...

Embodiment 1

[0056] Step 1101, weigh 10 g of tetraethyl orthosilicate, place it in an Erlenmeyer flask filled with 12 g of pure water and 5 g of ethanol, add 0.5 g of anhydrous acetic acid dropwise while stirring, seal and mix, and place in a water bath at 45°C Next, stir for 5h to obtain a clear silicon source solution.

[0057] Step 1201, weigh 2.2 g of polyvinyl alcohol (PVA) type 124, dissolve it in 19.8 g of pure water, and stir at 85° C. for 5 hours to prepare a polyvinyl alcohol solution.

[0058] Step 1301, weigh 6 g of zirconium oxychloride, dissolve it in 14 g of absolute ethanol to obtain a 30 wt % ethanol solution of zirconium oxychloride, add dropwise 2.4 g of anhydrous acetic acid, and stir at room temperature for 4 h, A zirconium source solution is prepared.

[0059] In step 1401, the prepared silicon source solution and polyvinyl alcohol solution are stirred and mixed evenly at room temperature at a mass ratio of 1:1, and left to age to obtain a silicon source spinning sol...

Embodiment 2

[0066] Step 2101, weigh 10 g of tetraethyl orthosilicate, place it in a conical flask filled with 6 g of pure water and 6 g of ethanol, add 0.1 g of anhydrous acetic acid dropwise while stirring, and mix in a water bath at 45°C , and stirred for 4h to obtain a clear silicon source solution.

[0067] Step 2201, weigh 2.2 g of polyvinyl alcohol (PVA) type 124, dissolve it in 19.8 g of pure water, and stir at 85° C. for 5 hours to prepare a polyvinyl alcohol solution.

[0068] Step 2301, weigh 2.5 g of zirconium oxychloride, dissolve it in 7.5 g of absolute ethanol to obtain a 25 wt % ethanol solution of zirconium oxychloride, add dropwise 0.8 g of anhydrous acetic acid, and stir at room temperature 4h to prepare the zirconium source solution.

[0069] In step 2401, the prepared silicon source solution and polyvinyl alcohol solution are stirred and mixed evenly at room temperature at a mass ratio of 1:0.8, and left to age to obtain a silicon source spinning solution as a core sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com