Preparation method of single-component room-temperature-curing high-temperature-resistant adhesive

A room-temperature-curing, high-temperature-resistant technology, applied in the direction of adhesives, polymer adhesive additives, adhesive types, etc., can solve the problems of insufficient temperature-resistant strength at 250°C and cumbersome construction process, etc., and achieve simple and easy production process, High retention rate, reasonable effect of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

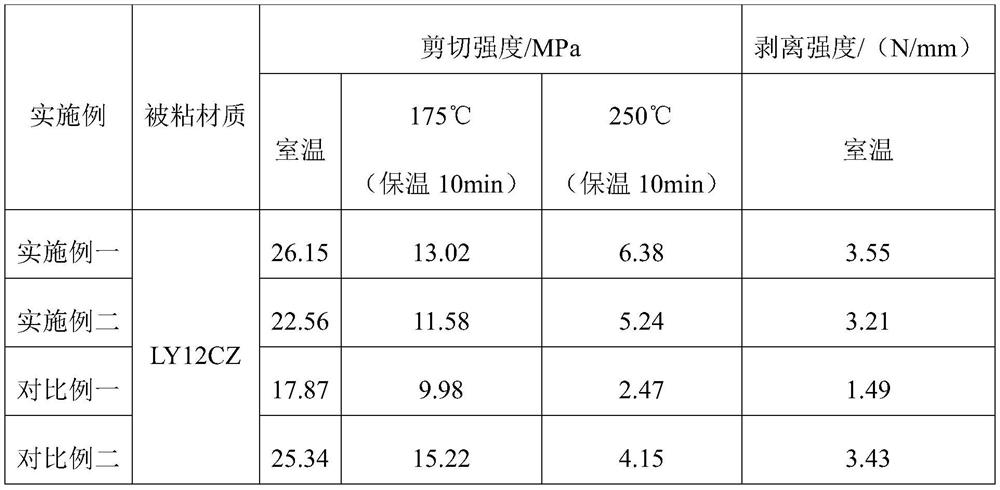

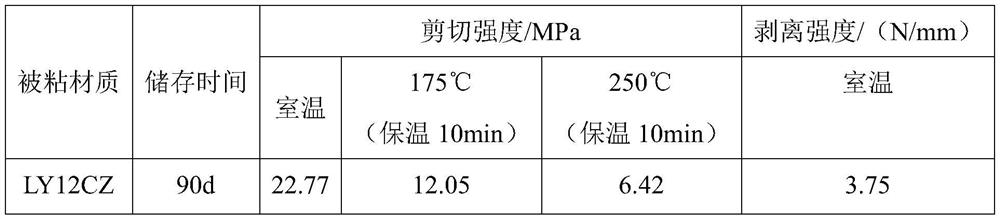

Examples

specific Embodiment approach 1

[0018] Embodiment 1: This embodiment is a preparation method of a one-component room temperature curing high temperature resistant adhesive, which is carried out according to the following steps:

[0019] 1. Weigh 70 to 95 parts of tetraglycidylamine epoxy resin, 5 to 30 parts of AFG-90 epoxy resin and 10 to 50 parts of toughening agent by mass, and weigh 70 to 95 parts of four Glycidylamine type epoxy resin, 5 parts to 30 parts of AFG-90 epoxy resin and 10 parts to 50 parts of toughening agent are added to the reaction kettle, and the 2 Under the condition that the atmosphere and temperature are 145℃~155℃, stir for 1h~4h, and cool to room temperature to obtain product A;

[0020] 2. Weigh 10 to 50 parts by mass of maleic anhydride, 5 to 30 parts of 3,3',4,4'-benzophenone tetracarboxylic dianhydride and 2 to 20 parts of 1, 4,5,8-Naphthalene tetracarboxylic anhydride, 10 to 50 parts of maleic anhydride, 5 to 30 parts of 3,3',4,4'-benzophenone tetracarboxylic dianhydride and 2 ...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the toughening agent described in step 1 is one or both of carboxyl-terminated liquid nitrile rubber and epoxy-terminated liquid nitrile rubber. mixture. Others are the same as the first embodiment.

specific Embodiment approach 3

[0031]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the tetraglycidylamine epoxy resin described in step 1 is AG-80 epoxy resin or MF-4101 epoxy resin. The tetraglycidylamine type epoxy resin described in one is AG-80 epoxy resin or MF-4101 epoxy resin. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com