Magnetic molecularly imprinted electrochemical sensor and preparation method and application thereof

A magnetic molecular imprinting and electrochemical technology, applied in the direction of material electrochemical variables, etc., can solve the problems of time-consuming, weak selectivity, and long sample detection time, and achieve good anti-interference characteristics and good specific recognition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing a magnetic molecularly imprinted electrochemical sensor, comprising the following steps,

[0046] S1: Fully grind 280mg of carbon powder, 30 μL of paraffin oil, and 70 mg of methotrexate magnetic molecularly imprinted polymer in a quartz mortar for 10 to 30 minutes to make a homogeneous magnetic molecularly imprinted carbon paste powder;

[0047] S2: Fill the magnetic molecularly imprinted carbon paste powder prepared in step S1 into the carbon paste electrode as a filler, and polish the electrode surface on a smooth weighing paper to prepare a magnetic molecularly imprinted carbon paste electrode;

[0048] S3: The magnetic molecularly imprinted carbon paste electrode prepared in step S2 was used as a working electrode, the platinum electrode was used as a counter electrode, and the saturated calomel electrode was used as a reference electrode to prepare a magnetic molecularly imprinted electrochemical sensor.

[0049] Further, the method for prep...

Embodiment 2

[0082] The difference between Example 2 and Example 1 is only that the amount of methotrexate magnetic molecularly imprinted polymer added in step S1 is different, and the rest are the same.

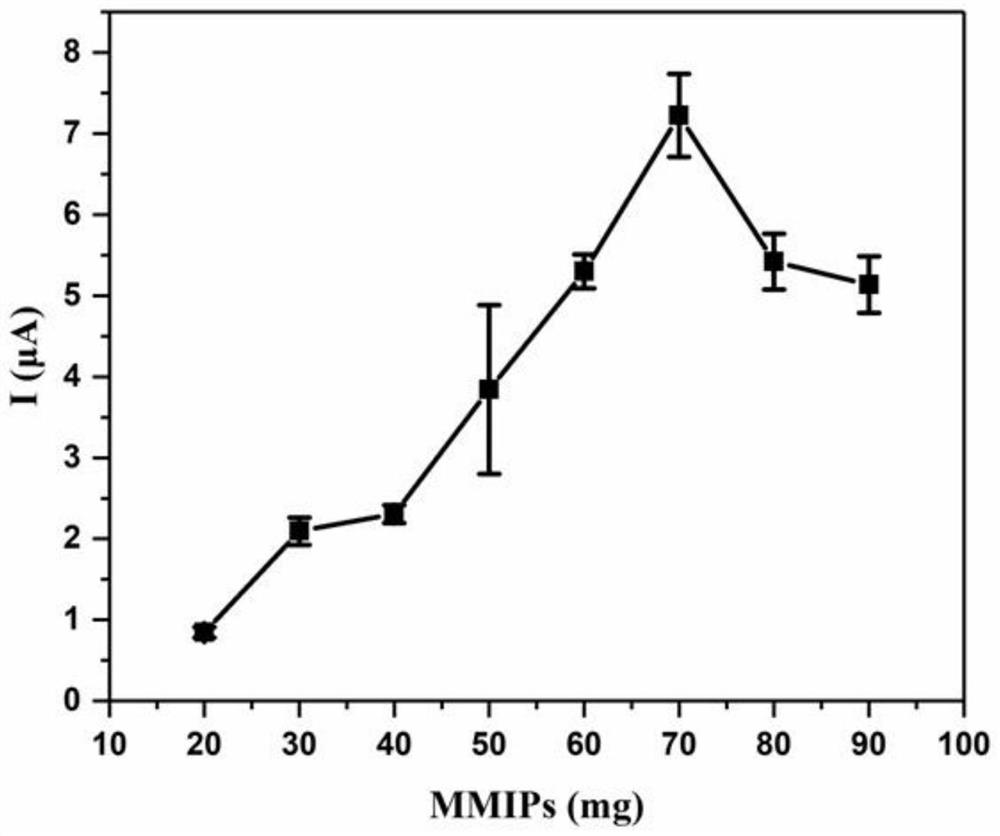

[0083] Add 20, 30, 40, 50, 60, 80, and 90 mg of methotrexate magnetic molecularly imprinted polymers respectively, and add the finally prepared magnetic molecularly imprinted carbon paste electrodes with the methotrexate molecularly imprinted polymers in Example 1 The magnetic molecularly imprinted carbon paste electrodes prepared with an amount of 70 mg were compared for performance, and the results were obtained from the attached image 3 shown.

[0084] From attached image 3 It can be seen from the figure that the magnetic molecularly imprinted carbon paste electrode prepared with the addition of 70 mg of methotrexate molecularly imprinted polymer in Example 1 has the largest current, indicating that when the amount of magnetic molecularly imprinted polymer is 70 mg The adsorption ...

Embodiment 3

[0086] The difference between the third embodiment and the first embodiment is only that the amount of paraffin oil added in the step S1 is different, and the rest are the same.

[0087] Add 10, 20, 40, and 50 μL of paraffin oil, respectively, and compare the performance of the finally prepared magnetic molecularly imprinted carbon paste electrode with the magnetic molecularly imprinted carbon paste electrode prepared by adding 30 μL of paraffin oil in Example 1. The results are from the attached Figure 4 shown.

[0088] From attached Figure 4 It can be seen from the figure that the magnetic molecularly imprinted carbon paste electrode prepared with the addition of paraffin oil of 30 μL in Example 1 has the largest current, indicating that the electrode prepared when the amount of paraffin oil is 30 μL has the best adsorption and catalytic effect on methotrexate , this is because when the amount of paraffin oil is less than 30 μL, the graphite powder and the magnetic molecu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com