Preparation method of avalanche photodetector

An avalanche photoelectric and detector technology, which is applied in the field of photodetectors, can solve problems such as detector inconsistency, difficulty in Zn diffusion, and reduced yield, so as to achieve reduced tunneling dark current, high crystal quality, and reduced impact The effect of the probability of wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

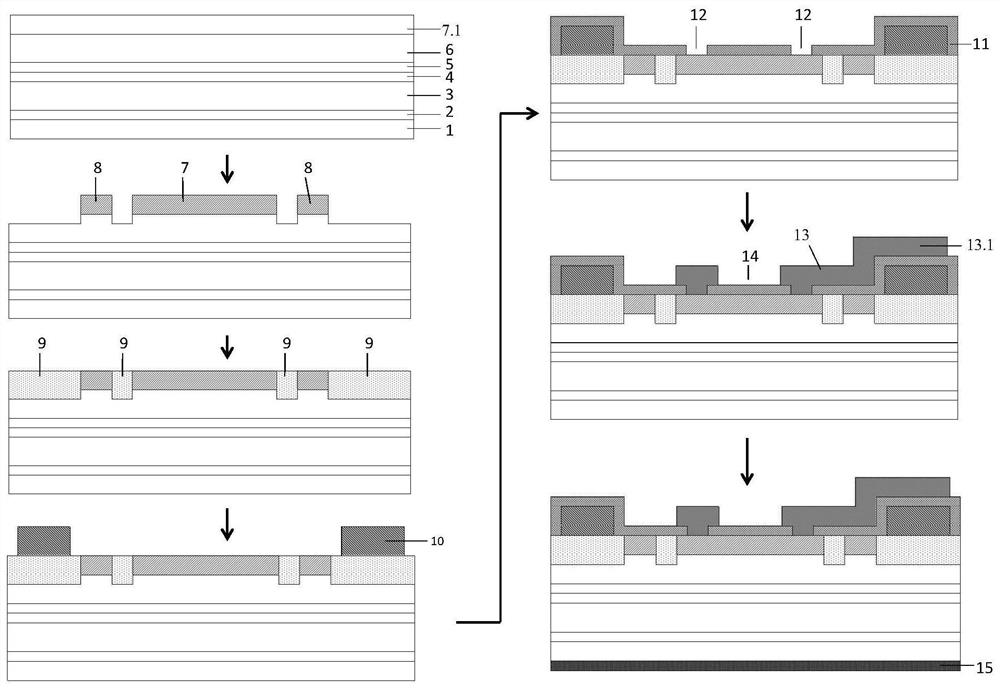

[0051] Such as figure 1 As shown, this implementation case introduces a method for preparing an avalanche photodetector, including the following steps:

[0052] Step 1: On the n-type InP substrate 1, grow n-type InP buffer layer 2, In 0.53 Ga 0.47 As absorption layer 3, In x Ga 1-x As y P 1-y Bandwidth gradient layer 4, n-type InP charge control layer 5, intrinsic InP multiplication layer 6, p-type InP capping layer 7.1.

[0053] Step 2: Using SiO 2 Patterning the hard mask, using an etching method to etch the p-type InP capping layer 7 and part of the intrinsic type InP multiplication layer 6 in a specific area, the thickness of the p-type InP capping layer 7.1 is 1um, and the thickness of the intrinsic InP multiplication layer 6 It is 500nm, and the etching depth is 1.2um, that is, the 1.2um etching depth includes the 1um thick p-type InP capping layer and the 0.2um deep intrinsic InP multiplication layer under the p-type InP capping layer, and the remaining InP cappi...

Embodiment 2

[0060] On the basis of the first embodiment, further, the n-type InP substrate 1 is heavily doped and forms an ohmic contact with the back electrode 15 . The n-type InP buffer layer 2 has a thickness of 0.5um, and its function is to better match the n-type InP substrate 1 and In 0.53 Ga 0.47 The difference in lattice constant between the As absorption layers 3 due to different growth conditions ensures the growth quality of the epitaxial layer.

[0061] The In 0.53 Ga 0.47 The thickness of the As absorption layer 3 is 2um, and the background doping concentration is less than 1×10 15 / cm 3 , this layer is a photogenerated carrier generation layer, designed to absorb photon energy with a wavelength of 1.0-1.7um as much as possible.

[0062] The In x Ga 1-x As y P 1-y The bandwidth gradient layer 4 consists of three layers, and the bandwidths of each layer are 0.95eV, 1.03eV and 1.13eV from bottom to top; the three-layer bandwidth gradient layer starts from In 0.53 Ga ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com