Preparation method of degradable metal molybdenum and alloy for ureteral and urethral stents

A technology of ureter and alloy, which is applied in the field of medical equipment, to achieve the effect of benefiting the recovery of body function, high mechanical strength, and enhancing the therapeutic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

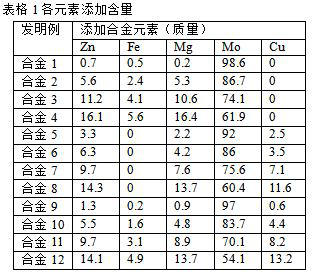

[0033] Embodiment 1: Alloy 1-molybdenum-zinc-iron-magnesium quaternary alloy

[0034] The material of the degradable metal molybdenum and alloy used in the ureter and urethral stent in this embodiment is a molybdenum-zinc-iron-magnesium alloy, and the preparation process specifically includes the following steps:

[0035]Ball milling: 0.3wt% Zn, 0.5wt% Fe, 0.2wt% Mg of high purity (99.999%), and the rest are Mo powder (R≤30μm), weighed according to a certain mass ratio. Mix the weighed powder evenly in a high-energy ball mill, and the mass ratio of ball to material is 10:1. Vacuumize the ball milling tank with the powder in turn with a vacuum pump, and then pass in argon to fill the whole ball milling tank. The operation mode of the ball mill was set to run forward and reverse alternately at intervals, the speed was 400-600 r / min, and the total time of ball milling was 10-48 h.

[0036] Vacuum melting: Repeated vacuuming 2-4 times to 6×10 -2 Pa-5×10 -3 Pa, close the valve ...

Embodiment 2

[0041] Embodiment 2: alloy 2-molybdenum-zinc-iron-magnesium-copper quinary alloy

[0042] The degradable metal molybdenum and alloys used in the ureter and urethral stent in this embodiment are made of molybdenum-zinc-iron-magnesium-copper alloy, and the preparation process specifically includes the following steps:

[0043] Ball milling: High-purity (99.99%) 17wt%Zn, 6wt%Fe, 17wt%Mg, 15wt%Cu, and the rest are Mo powder (R≤30 μm), weighed according to a certain mass ratio. Mix the weighed powder evenly in a high-energy ball mill, and the mass ratio of ball to material is 10:1. Vacuumize the ball milling tank with the powder in turn with a vacuum pump, and then pass in argon to fill the whole ball milling tank. The operation mode of the ball mill was set to run forward and reverse alternately at intervals, the speed was 400-600 r / min, and the total time of ball milling was 10-48 h.

[0044] Vacuum melting: Repeated vacuuming 2-4 times to 6×10 -2 Pa-5×10 -3 Pa, close the val...

Embodiment 3

[0049] Example 3: Alloy 3-molybdenum-zinc-copper-magnesium quaternary alloy

[0050] The material of the degradable metal molybdenum and alloy used in the ureter and urethral stent in this embodiment is a molybdenum-zinc-copper-magnesium alloy. The preparation process specifically includes the following steps:

[0051] Ball milling: high-purity (99.99%) 10wt% Zn, 8.5wt% Mg, 7.5wt% Cu, and the rest Mo powder (R≤30 μm), weighed according to a certain mass ratio. Mix the weighed powder evenly in a high-energy ball mill, and the mass ratio of ball to material is 10:1. Vacuumize the ball milling tank with the powder in turn with a vacuum pump, and then pass in argon to fill the whole ball milling tank. The operation mode of the ball mill is set to run forward and reverse alternately at intervals, the speed is 400-600 r / min, and the total time of ball milling is 10-48h.

[0052] Vacuum melting: Repeated vacuuming 2-4 times to 6×10 -2 Pa-5×10 -3 Pa, close the valve of the furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com