Method and device for producing high-nickel alloy and reduced iron through coal-based coking magnetic separation

A technology of reducing iron and coal-based, applied in coal-based coking reduction roasting coke magnetic separation to produce high-nickel alloy and reduced iron, coal-based direct reduction roasting kiln and mineral optimization field, can solve the frustration of industrial production and application of gas-based shaft furnace process , Nickel recovery rate, nickel alloy grade is not high, thermal energy recycling efficiency is low, etc., to achieve the effects of easy promotion, huge energy-saving development potential, and relatively small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

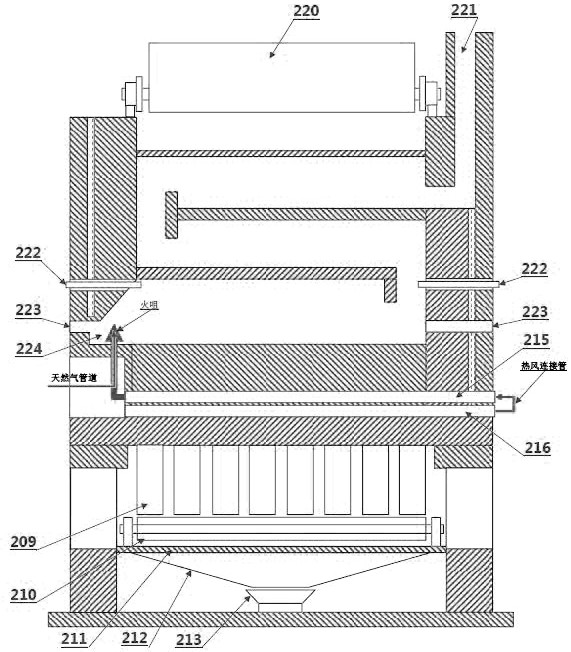

Image

Examples

Embodiment 1

[0080] A lateritic nickel ore contains 0.81% Ni and 48.17% Fe. Follow these steps:

[0081] (1) Raw material treatment: Ni0.81%, Fe48.17% laterite nickel ore is sieved and granulated, heated and dried, crushed and screened to obtain dry nickel ore particle materials with a particle size of 6-40mm; the prepared reducing agent The coking coal raw coal and the separated coking coal are mixed according to the mass percentage of 40%, and the coking coal mixing and briquetting machine is heated and dried to obtain dry coking coal pellets with a particle size of 45-55mm; % and nickel ore particles with a particle size of 6-40 mm are mixed through a mixing output device to obtain a mixture of laterite nickel ore particles with a moisture weight percentage <10%.

[0082] (2) Coal-based coking reduction roasting: Fill the coal-based coking reduction roasting test kiln with laterite nickel ore particle mixture; lay the stacked thickness in the preheating pool with a thickness of 200-300...

Embodiment 2

[0088] A lateritic nickel ore contains 0.92% nickel Ni and 49.84% iron Fe. Follow these steps:

[0089] (1) Raw material processing: Ni0.92%, Fe49.84% laterite nickel ore is granulated, dried, crushed and screened to obtain dry nickel ore particle materials with a particle size of 6-40mm; Percentage 40% mixing and pressing ball drying treatment to obtain dry coke balls with a particle size of 45-55mm; the dry coke balls with a particle size of 45-55mm are passed through the mixing output device according to the mass percentage of 30% and nickel ore particles with a particle size of 6-40mm Mix evenly to obtain laterite nickel ore granular mixture.

[0090] (2) Coal-based coking reduction roasting: The laterite nickel ore particle mixture is roasted in a coal-based coking roasting test kiln to obtain coking reduction roasting materials.

[0091](3) Coke Separation Circular Grinding Optimal Separation of Iron and Nickel: The coke reduction roasted material is separated by a sie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com