Method for improving cutting precision of screw tap and prolonging service life of screw tap

A tap and precision technology, which is applied in the field of ion beam material surface modification and new materials, can solve the problems of changing the production size of the tap, increasing the size of the screw hole, and increasing the diameter, so as to achieve good nucleation, reduce friction, and reduce texture. gentle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

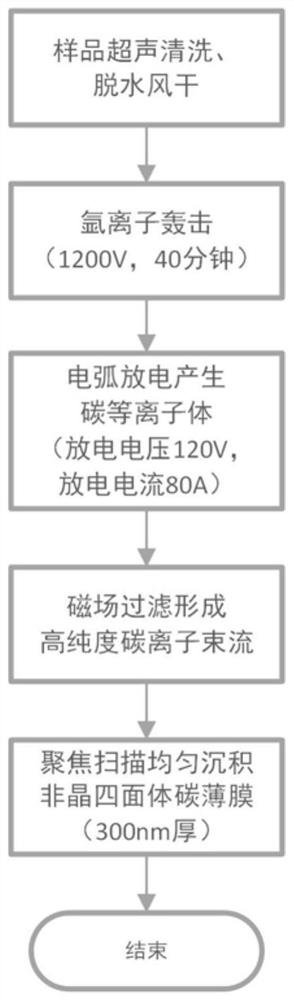

[0037] (1) Cleaning, first use a brush to brush off the grease in the slit of the tap, then put it into an ultrasonic cleaning tank, degrease and clean the tap for 40 minutes, dehydrate and air dry, then put it in a vacuum chamber;

[0038](2) Ion beam surface treatment, when the vacuum reaches 1×10 -3 Pa, start a cold cathode gas ion source, use argon ions to bombard the surface of the tap, the discharge voltage of the ion source is 500V, the extraction voltage is 1200V, the extraction current is 200mA, and the bombardment time is 40 minutes;

[0039] (3) Film deposition process, first start the arc ion source to form an arc discharge, the arc ion source anode cylinder and cathode target are made of graphite with a purity of more than 99.99%, control the discharge voltage to 120V, discharge current 80A, on the graphite cathode target Generate arc discharge, which in turn generates carbon plasma in the anode cylinder;

[0040] (4) Lead the carbon plasma out of the discharge c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com