A method for large-scale preparation of hfo2-tho2 ultra-high temperature oxide composite ceramics

A composite ceramic and ultra-high temperature technology, which is applied in the field of large-scale preparation of HfO2-ThO2 ultra-high temperature oxide composite ceramics, can solve the problems of difficult sintering, low production efficiency, and complicated process of composite ceramics, and reduce the production cost. cost, porosity reduction, and bulk density enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

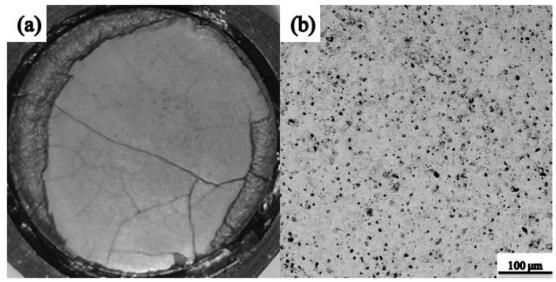

Embodiment 1

[0128] 1) with HfO 2 (Shanghai McLean Biochemical Technology Co., Ltd., purity 99.99%) and ThO 2 (Shandong Dengnuo New Material Technology Co., Ltd.) is the matrix material of composite ceramics, and HfO in composite ceramics 2 with ThO 2 The ratio is fixed at 19:1 (molar ratio), and 3 at%Al is added 2 o 3 The powder is ball-milled, poured into absolute ethanol as the ball-milling medium, and milled for 12 hours using a drum-type ball mill at a speed of 50 r / min, dried at 50°C for 24 hours, and passed through a 200-mesh sieve;

[0129] 2) According to the mass ratio of powder: solution = 25:0.9~1.1, add PVA aqueous solution with a mass concentration of 2% to the powder, and grind it evenly in an alumina grinding body, pass through a 40-mesh sieve and let it stand overnight;

[0130] 3) Take about 26g of powder and place it in a φ30mm cemented carbide mold (the material is YG8, Renqiu Tengxin Mold Co., Ltd.), pressurize at a constant speed to the maximum pressure of 110MPa,...

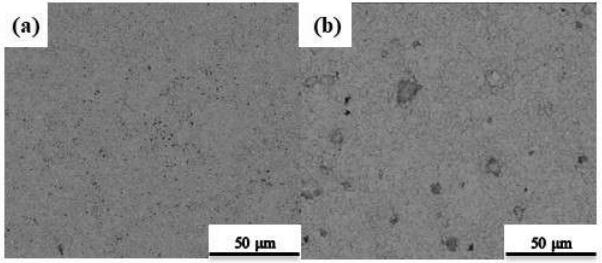

Embodiment 2

[0143] 1) with HfO 2 (Shanghai McLean Biochemical Technology Co., Ltd., purity 99.99%) and ThO 2 (Shandong Dengnuo New Material Technology Co., Ltd.) is the matrix material of composite ceramics, and HfO in composite ceramics 2 with ThO 2 The ratio is fixed at 19:1 (molar ratio), and 3 at% CaO powder is added for ball milling, poured into absolute ethanol as the ball milling medium, using a drum mill at a speed of 50r / min for 12h, and drying at 50°C for 24h , through a 200-mesh sieve;

[0144] 2) According to the mass ratio of powder: solution = 25:0.9~1.1, add PVA aqueous solution with a mass concentration of 2% to the powder, and grind it evenly in an alumina grinding body, pass through a 40-mesh sieve and let it stand overnight;

[0145] 3) Take about 26g of powder and place it in a φ30mm cemented carbide mold (the material is YG8, Renqiu Tengxin Mold Co., Ltd.), pressurize at a constant speed to the maximum pressure of 110MPa, and hold the pressure for 120s;

[0146] 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com