Solid emulsifier with good emulsification stability for oil-based drilling fluid as well as preparation method and application of solid emulsifier

An oil-based drilling fluid and emulsion stabilization technology, applied in the field of drilling fluid emulsifier, can solve the problems of poor emulsification stabilization effect of emulsifier, and achieve good emulsion stabilization ability, enhanced hydrophilic performance, and good emulsification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing a solid emulsifier for oil-based drilling fluid with good emulsification stability, comprising the following steps:

[0027] Mixing the first rosin and the first maleic anhydride to perform a Diels-Alder reaction to obtain an addition product;

[0028] mixing the addition product with ethylenediamine to perform a first acylation reaction to obtain a first acylation reaction product;

[0029] mixing the acylation reaction product with the second maleic anhydride to perform a second acylation reaction to obtain a second acylation reaction product;

[0030] Mixing the second acylation reaction product with calcium oxide for neutralization reaction to obtain an intermediate product;

[0031] The intermediate product, sodium dodecylbenzenesulfonate and the second rosin are mixed to obtain the solid emulsifier for oil-based drilling fluid with good emulsification stability.

[0032] In the present invention, the first rosin is m...

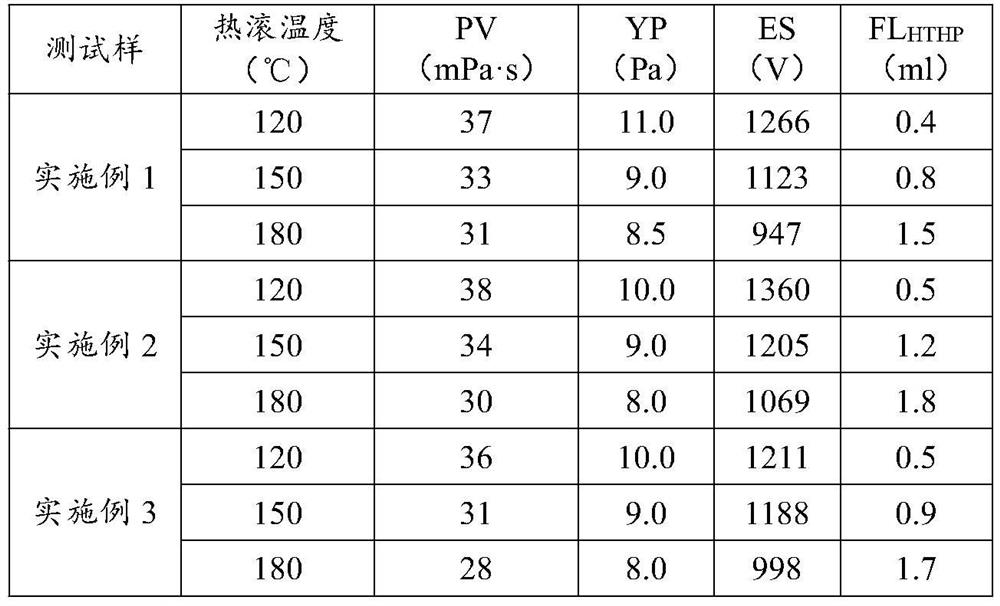

Embodiment 1

[0061] (1) Heat 50 parts of gum rosin to melt, stir and add 15 parts of maleic anhydride, heat up to 220°C, Diels-Alder reaction occurs, the reaction time is 2 hours, and an addition product is formed;

[0062] (2) Slowly add 10 parts of ethylenediamine dropwise to the resulting addition product (dropping in 5 minutes), an acylation reaction occurs, react for 4 hours, and the product is the initial reaction material; after cooling down to 80°C, Add 10 parts of maleic anhydride to the reaction mixture for 1.5h;

[0063] (3) Add 15 parts of calcium oxide to the product of step (2), neutralize at a temperature of 80° C. for 2 hours, and pulverize the solid after cooling to room temperature to obtain a yellow powdery intermediate product;

[0064] (4) Mix 80 parts of intermediate product, 15 parts of sodium dodecylbenzenesulfonate, and 5 parts of gum rosin powder (particle size is 120 mesh), and the obtained yellow powder is the oil base with good emulsification stability of the t...

Embodiment 2

[0066] 1) Heat 45 parts of gum rosin to melt, stir and add 18 parts of maleic anhydride, heat up to 180°C, Diels-Alder reaction occurs, the reaction time is 4 hours, and an addition product is formed;

[0067] (2) Slowly add 12 parts of ethylenediamine dropwise to the resulting addition product (dropping in 10 minutes), an acylation reaction occurs, react for 1 hour, and the product is the initial reaction material; after cooling down to 100°C, Add 8 parts of maleic anhydride to , react for 1h;

[0068] (3) Add 17 parts of calcium oxide to the product obtained in step (2), neutralize for 1 hour at a temperature of 100° C., and pulverize the solid after cooling to room temperature to obtain a yellow powdery intermediate product;

[0069] (4) Mix 75 parts of intermediate product, 17 parts of sodium dodecylbenzenesulfonate, and 8 parts of gum rosin powder (150 mesh in particle size), and the obtained yellow powder is the oil base with good emulsification stability of the target p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com