Connecting piece of sand stabilization plates and preparation method of connecting piece

A technology for sand-fixing boards and connectors, applied in the field of sand-fixing, can solve the problems of small force between connectors and sand surface, cumbersome construction, etc., and achieve the effect of cheap materials, less staffing, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

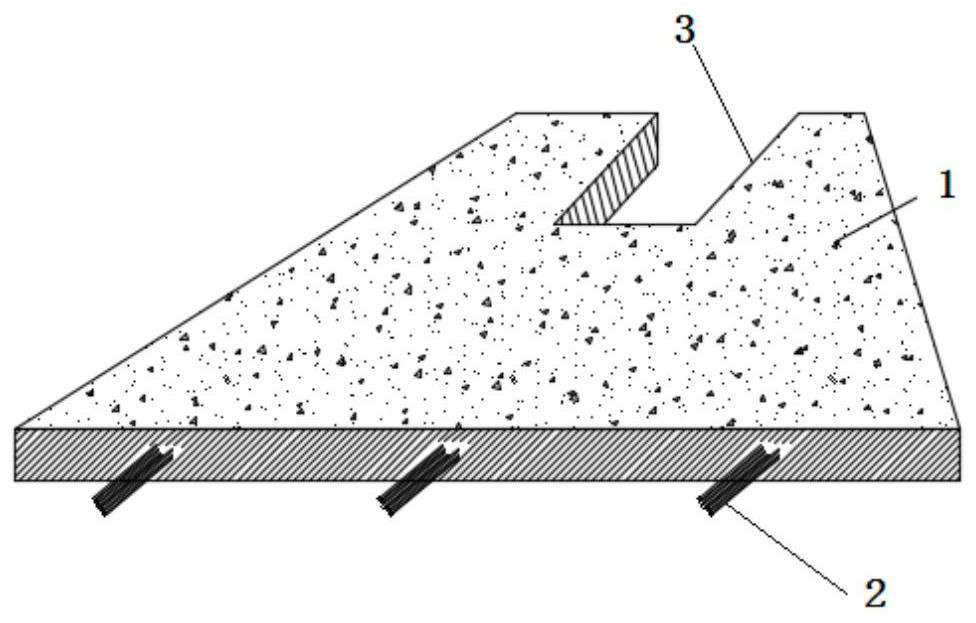

[0058] Such as figure 1 As shown, a connector for a sand-fixing board includes a positioning board 1 solidified by magnesium cement mortar 6 and a rib 2 with one end solidified on the inner bottom of the positioning board, wherein the top of the positioning board 1 is formed with a Groove 3 where the sand-fixing board is inserted.

[0059] When in use, insert the sand-fixing plate 4 into the groove 3 to realize the fixed connection between the connector and the sand-fixing plate, and after the connection, the positioning plate 1 and the sand-fixing plate cross vertically.

[0060] The ribs are preferably arranged perpendicular to the bottom edge of the positioning plate to improve the wind resistance of the connector. At the same time, the ribs can also have a certain angle with the bottom edge. The number of ribs on each connector is preferably but not limited to 2-5 One, the ribs are plant fibers, thin metal rods or magnesium bars. The plant fibers can be but not limited t...

Embodiment 2

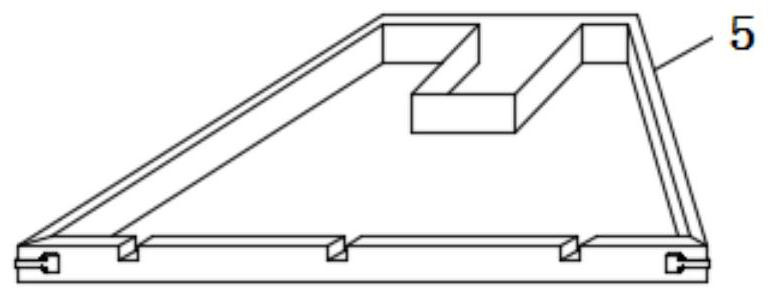

[0088] The mold 5 structure of preparing described connector is as follows:

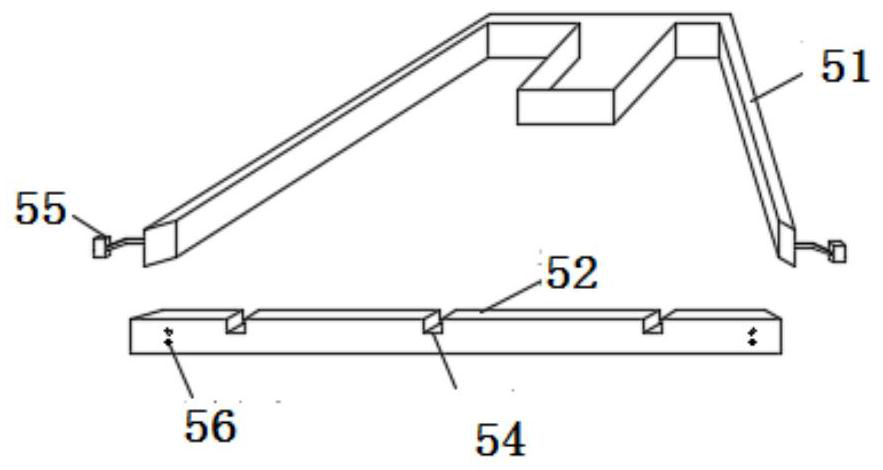

[0089] Described mold comprises detachably connected half mold frame 51 and perforated template 52, and described half mold frame 51 and perforated template 52 encircle and form mold frame, and mold cavity 53 is formed in the described mold frame, and described mold cavity The shape and size are the same as the shape and size of the connecting piece of the sand-fixing plate, and a plurality of holes 54 are formed on the hole template, and each hole is used for inserting a bar. The inner side length of the opening is 1cm-5cm.

[0090] The half-mold frame is similar to a W-shaped mold, and the opening template is a strip-shaped opening mold. The W-shaped mold and the opening mold are made of stainless steel plates. When the half-mould frame and the opening template are fixed together, the overall structure of the mold is formed ( T-die). Such as Image 6 As shown, the height of the T-shaped mold is ...

Embodiment 3

[0093] Utilize the magnesium cement mortar 6 in embodiment 1 and the method for the mold preparation connector of embodiment 2, may further comprise the steps:

[0094] Step 1, assemble the mold frame and the hole template;

[0095] Step 2, the rib in embodiment 1 is inserted in the opening, so that one end of the rib is located in the mold cavity, and the other end is positioned at the outside of the mold; the length of the rib reserved outside the mold is 5-20cm (this Embodiment reserves 7cm), such as Figure 7 shown.

[0096] Step 3, inject the magnesium cement mortar described in Example 1.1-1.3 into the mold cavity, and maintain in the air at 0-30°C until the magnesium cement mortar initially sets, preferably, maintain in the air for 8- 36h (the present embodiment curing time 24h) hardening;

[0097] Step 4: Disassemble and open the half-mold frame and the opening formwork, and the joints after demoulding are cured in the air at 0-30°C until the magnesium cement mortar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com