Method for preparing Pickering emulsion by using modified glycinin micelles

A technology of soybean globin and micelles, which can be used in food ingredients as pH modifiers, applications, food ultrasonic treatment, etc., can solve the problems of limited applications, achieve good amphiphilicity, easy operation, and good food safety The effect of sex and environmental compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

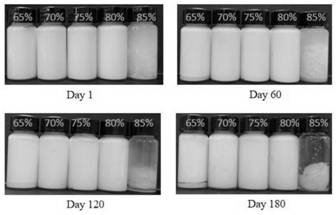

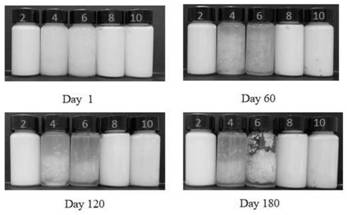

Image

Examples

Embodiment 1

[0062] First, grind soybean meal into powder, pass through a 100-mesh sieve to obtain fine powder; fully mix soybean powder with distilled water 1:15 (g / mL), adjust the pH of the suspension to 7.5 with 1mol / L NaOH, and stir at room temperature for 2 hours; Centrifuge for 30min (9000g, 4°C), keep the supernatant; add NaHSO with a final concentration of 1.04g / L 3 Stir evenly, let stand for 30 minutes, adjust the pH to 6.4; hydrate in a refrigerator at 4°C for 16 hours, then centrifuge for 20 minutes (6500g, 4°C), completely dissolve the precipitate in distilled water, adjust the pH to 7.5, and then dialyze for 48 hours, controlled by an ice box The ambient temperature is below 4°C; pre-freeze at -80°C and freeze-dry for 48 hours to obtain SG powder for use.

[0063] Take an appropriate amount of the above SG powder, add deionized water, stir at room temperature for 2 hours, put it in a refrigerator at 4°C to hydrate overnight to fully dissolve; centrifuge for 20 minutes (8000g, ...

Embodiment 2

[0066] First, grind soybean meal into powder, pass through a 100-mesh sieve to obtain fine powder; fully mix soybean powder with distilled water 1:15 (g / mL), adjust the pH of the suspension to 7.5 with 1mol / L NaOH, and stir at room temperature for 2 hours; centrifuge Centrifuge for 30min (9000g, 4°C), keep the supernatant; add NaHSO with a final concentration of 1.04g / L 3 Stir evenly, let stand for 30 minutes, adjust the pH to 6.4; hydrate in a refrigerator at 4°C for 16 hours, then centrifuge for 20 minutes (6500g, 4°C), completely dissolve the precipitate in distilled water, adjust the pH to 7.5, and then dialyze for 48 hours, controlled by an ice box The ambient temperature is below 4°C; pre-freeze at -80°C and freeze-dry for 48 hours to obtain SG powder for use.

[0067] Take an appropriate amount of the above SG powder, add deionized water, stir at room temperature for 2 hours, put it in a refrigerator at 4°C to hydrate overnight to fully dissolve; centrifuge for 20 minut...

Embodiment 3

[0070] First, grind soybean meal into powder, pass through a 100-mesh sieve to obtain fine powder; fully mix soybean powder with distilled water 1:15 (g / mL), adjust the pH of the suspension to 7.5 with 1mol / L NaOH, and stir at room temperature for 2 hours; centrifuge Centrifuge for 30min (9000g, 4°C), keep the supernatant; add NaHSO with a final concentration of 1.04g / L 3 Stir evenly, let stand for 30 minutes, adjust the pH to 6.4; hydrate in a refrigerator at 4°C for 16 hours, then centrifuge for 20 minutes (6500g, 4°C), completely dissolve the precipitate in distilled water, adjust the pH to 7.5, and then dialyze for 48 hours, controlled by an ice box The ambient temperature is below 4°C; pre-freeze at -80°C and freeze-dry for 48 hours to obtain SG powder for use.

[0071] Take an appropriate amount of the above SG powder, add deionized water, stir at room temperature for 2 hours, put it in a refrigerator at 4°C to hydrate overnight to fully dissolve; centrifuge for 20 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com