Method for simultaneously recycling positive electrode and negative electrode of lithium ion battery by adopting multi-layer electrode structure

A lithium-ion battery and multi-layer electrode technology, which is applied in battery recycling, chemical instruments and methods, recycling technology, etc., can solve the problem of high tank pressure, inability to recycle positive and negative materials of batteries at the same time, and release of toxic gases, etc. problem, to achieve good effect, low tank pressure and high economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

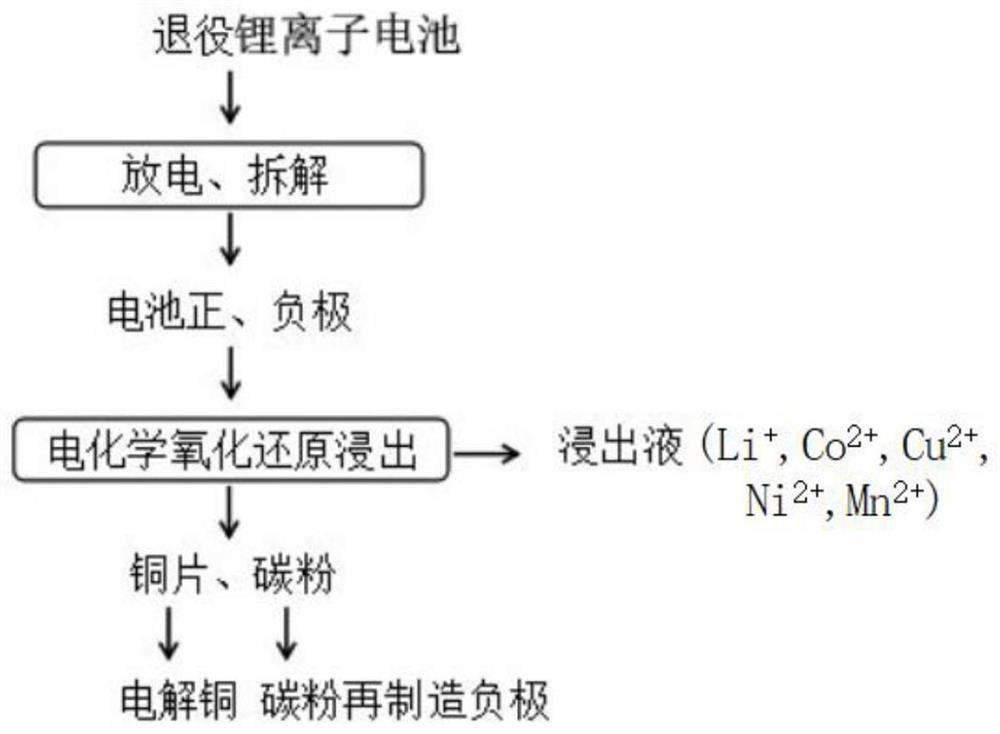

[0088] A method for simultaneously recycling the positive and negative electrodes of a lithium-ion battery by adopting a multilayer electrode structure is realized through the following steps:

[0089] (1) Disassembly:

[0090] Fully discharge the decommissioned lithium-ion battery, manually disassemble and remove the shell in the glove box, separate the diaphragm and negative electrode, take out the positive electrode sheet (ie positive electrode material) and negative electrode sheet (ie negative electrode material); dry the positive electrode and negative electrode to make the electrolyte, etc. The organic solvent is volatilized, and this process does not require complicated pretreatment before leaching.

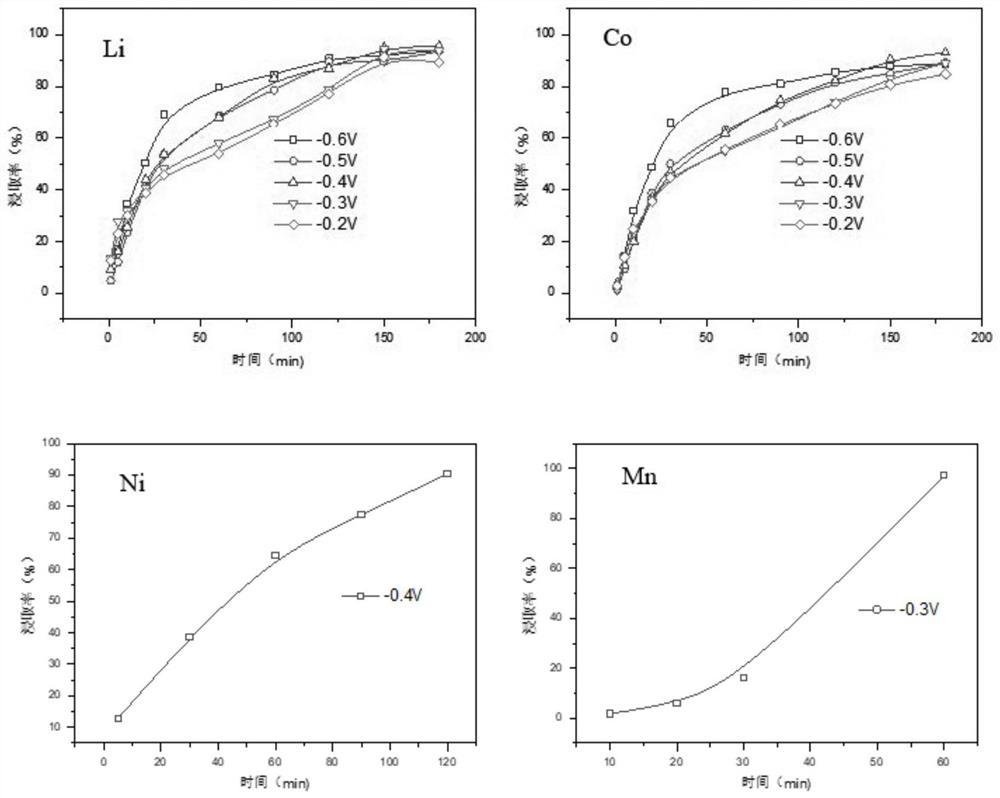

[0091] (2) Electroredox leaching of lithium, cobalt, nickel, manganese, copper and activated carbon powder:

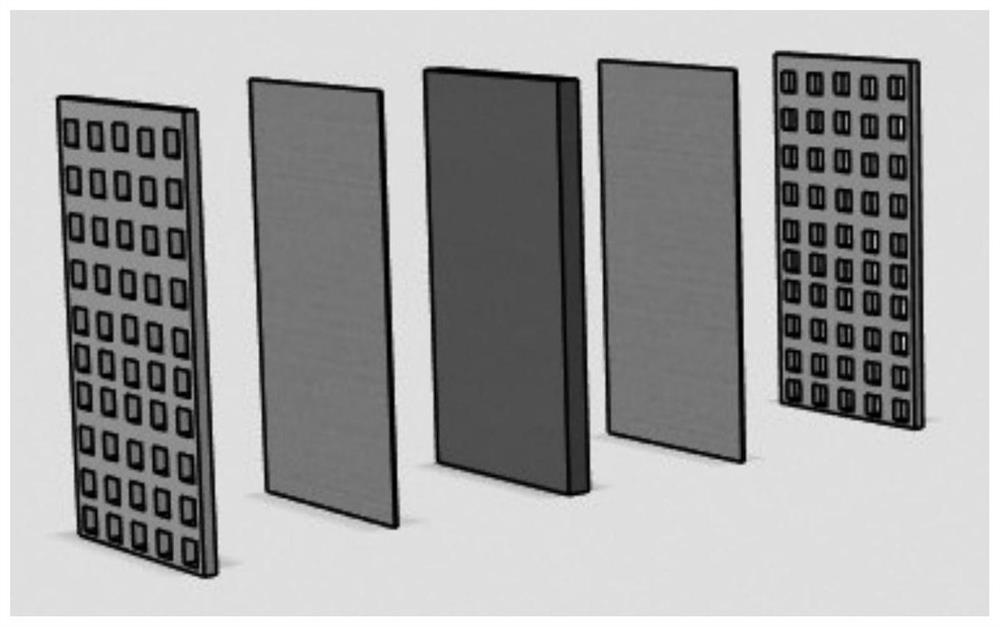

[0092] After the positive and negative electrodes are dry, add 0.5M sulfuric acid to the traditional three-electrode system. The anode is an electrode with a san...

Embodiment 2

[0098] A method for simultaneously recycling the positive and negative electrodes of a lithium-ion battery by adopting a multilayer electrode structure is realized through the following steps:

[0099] (1) Disassembly:

[0100] Fully discharge the decommissioned lithium-ion battery, manually disassemble and remove the shell in the glove box, separate the diaphragm and negative electrode, take out the positive electrode sheet (ie positive electrode material) and negative electrode sheet (ie negative electrode material); dry the positive electrode and negative electrode to make the electrolyte, etc. The organic solvent is volatilized, and this process does not require complicated pretreatment before leaching.

[0101] (2) Electroredox leaching of lithium, cobalt, nickel, manganese, copper and activated carbon powder:

[0102] After the positive and negative electrodes are dry, add 0.5M sulfuric acid to the traditional two-electrode system (cathode and anode), where the anode is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com