Polyamic acid and preparation method thereof, and polyimide and polyimide fiber of polyamic acid

A technology of polyamic acid and polyimide, which is applied in the field of polyimide, can solve the problems of poor fiber performance uniformity and stability, random molecular chain structure sequence, and improve mechanical strength, so as to enhance the force between molecular chains , good mechanical properties, the effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

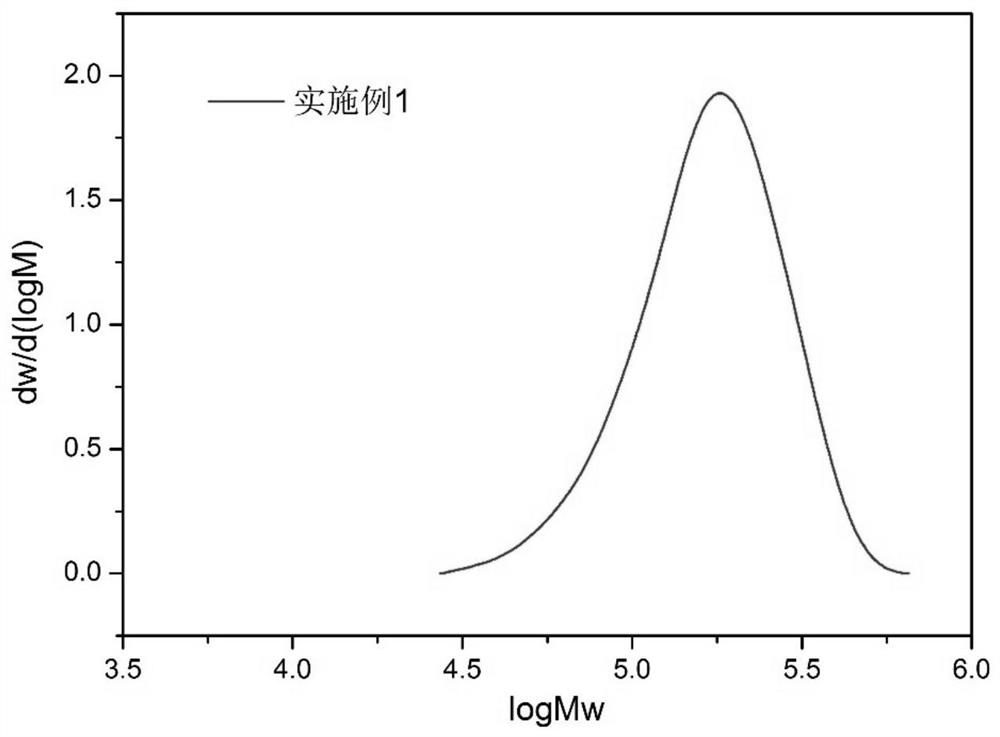

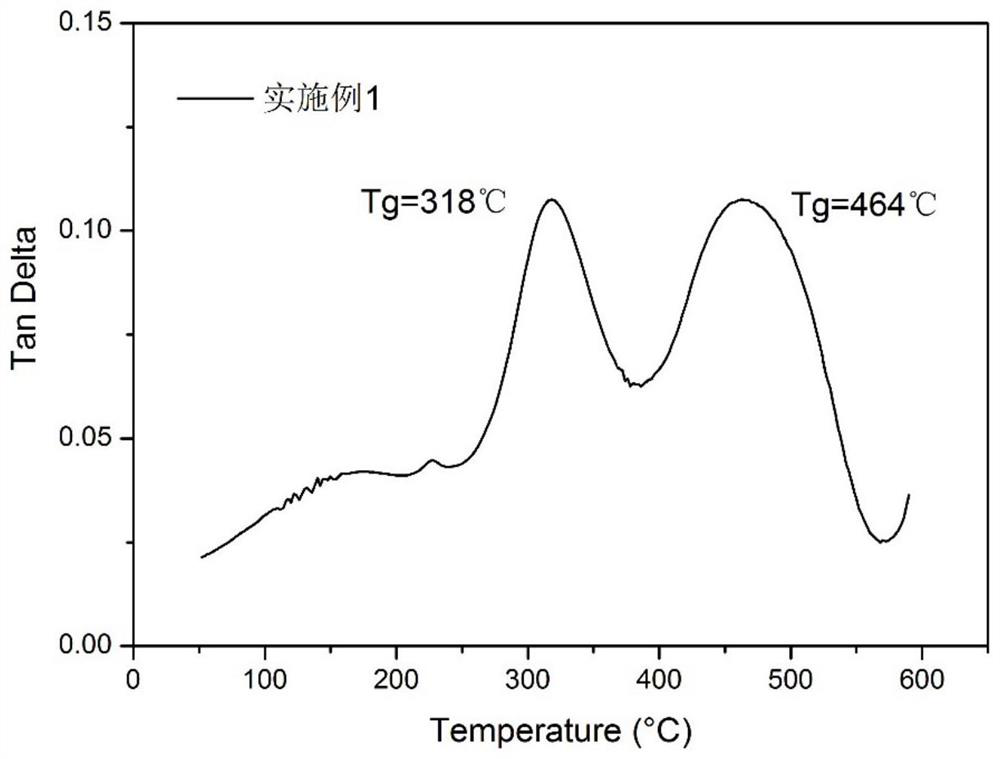

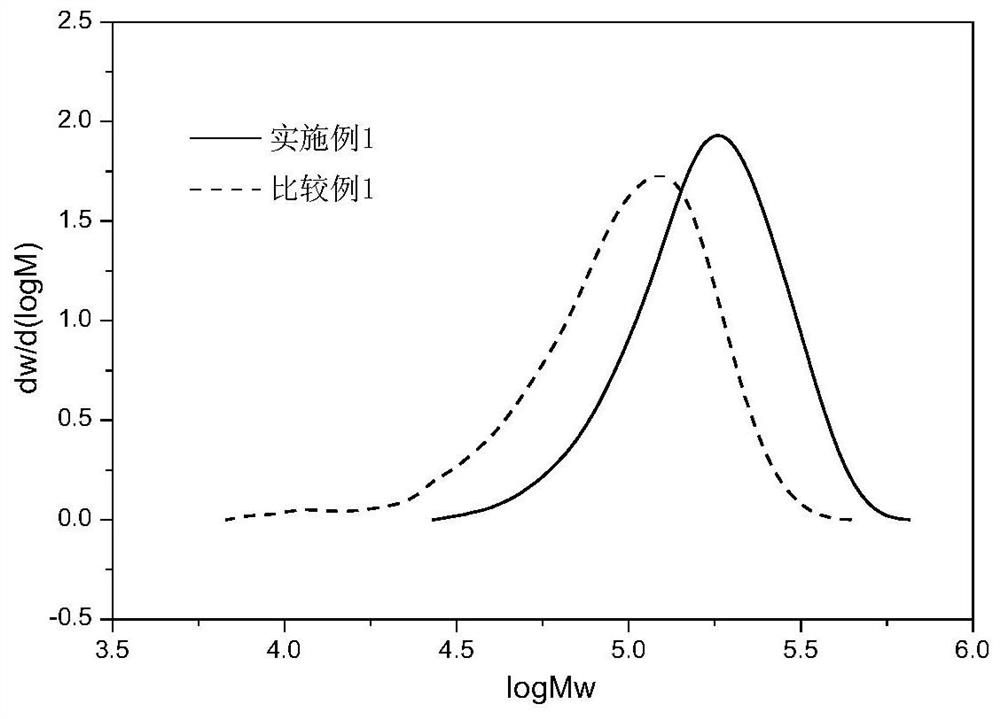

[0111] [Example 1] (the molar percentage of BPDA / BIA block segment in the total segment is 70%)

[0112] 1. Stock solution preparation: (1) Dissolve 5.48Kg (24.44mol) 2-(4-aminophenyl)-5-aminobenzimidazole (BIA) in 85Kg N,N-dimethylacetamide (DMAc) , at 25°C N 2 Stir under protection, after completely dissolving, add 6.47Kg (22.00mol) 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA), continue stirring for 1h after the addition, and obtain polyamic acid (PAA) polymer solution 1;

[0113] (2) The same polymerization condition, 0.75Kg (6.97mol) p-phenylenediamine (p-PDA) is dissolved in N,N-dimethylacetamide, 1.37Kg (6.27mol) pyromellitic dianhydride ( PMDA) was added in the diamine solution, fully stirred for 1.5h to obtain prepolymer solution 2;

[0114] (3) fully mix prepolymer solution 1 and prepolymer solution 2 for 1.5h to obtain prepolymer solution 3;

[0115] (4) Add 0.92Kg (3.14mol) 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA) into the prepolymer solution...

Embodiment 2

[0122] [Example 2] (BPDA / BIA segment accounted for 20% molar percentage of the total segment)

[0123] 1. Stock solution preparation: (1) Dissolve 1.99Kg (8.89mol) 2-(4-aminophenyl)-5-aminobenzimidazole (BIA) in 85Kg N,N-dimethylacetamide (DMAc) , at 25°C N 2 Stir under protection, after completely dissolving, add 2.35Kg (8.00mol) 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA), continue stirring for 1h after the addition, and obtain polyamic acid (PAA) polymer solution 1;

[0124] (2) Under the same polymerization conditions, 3.36Kg (31.12mol) p-phenylenediamine (p-PDA) was dissolved in N,N-dimethylacetamide, 6.11Kg (28.01mol) pyromellitic dianhydride ( PMDA) was added in the diamine solution, fully stirred for 1h to obtain prepolymer solution 2;

[0125] (3) fully mixing prepolymer solution 1 and prepolymer solution 2 for 1 h to obtain prepolymer solution 3;

[0126] (4) 1.18Kg (4.00mol) 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA) was added to the prepolyme...

Embodiment 3

[0128] [Example 3] (the molar percentage of BPDA / BIA block segment accounting for the total segment is 50%)

[0129] 1. Stock solution preparation: (1) Dissolve 3.98Kg (17.74mol) 2-(4-aminophenyl)-5-aminobenzimidazole (BIA) in 85Kg N,N-dimethylacetamide (DMAc) , at 25°C N 2 Stir under protection, after completely dissolving, add 4.70Kg (15.97mol) 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA), continue stirring for 1h after the addition, and obtain polyamic acid (PAA) polymer solution 1;

[0130] (2) Under the same polymerization conditions, 2.84Kg (14.19mol) 4,4'-diaminodiphenyl ether (ODA) was dissolved in N,N-dimethylacetamide, and 2.78Kg (12.78mol) pyromellitic Acid dianhydride (PMDA) was added to the diamine solution, and fully stirred for 1 hour to obtain prepolymer solution 2;

[0131] (3) fully mixing prepolymer solution 1 and prepolymer solution 2 for 1 h to obtain prepolymer solution 3;

[0132] (4) 0.69Kg (3.19mol) pyromellitic dianhydride (PMDA) was added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com