Imitation gold alloy and its preparation method and application

A technology of imitating gold and alloys, which is applied in the field of imitating gold alloys and its preparation, can solve the problems of difficult industrial mass production of nano powder, high alloy manufacturing costs, and low alloy hardness, so as to improve hardness, structural stability, and corrosion resistance Performance, strong anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

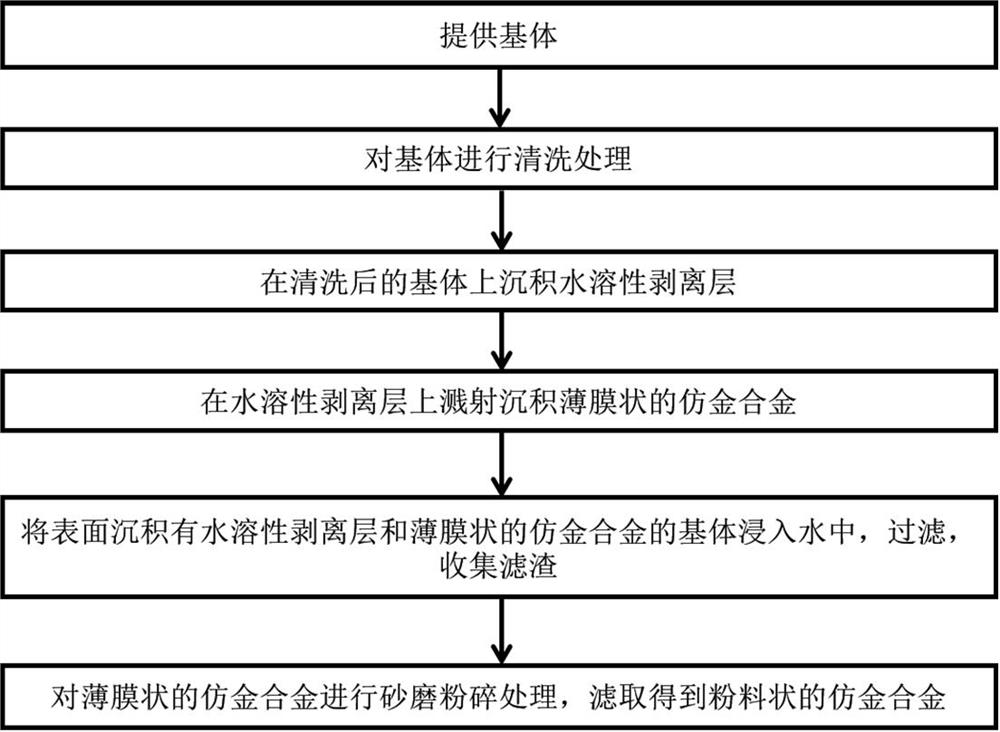

[0056] The present invention also provides a method for preparing an imitation gold alloy, which is to prepare the imitation gold alloy by means of physical vapor deposition;

[0057] The chemical formula of the imitation gold alloy is Zr x Si y Ni z Cu 1-x-y-z , x, y and z are atomic percentages, and x, y and z satisfy: 0.05≤x≤0.13, 0.02≤y≤0.10, 0.02≤z≤0.05.

[0058] It can be understood that the pseudo-gold alloy obtained by physical vapor deposition is in the form of a thin film.

[0059] In one embodiment, the physical vapor deposition method is at least one of vacuum evaporation, magnetron sputtering coating, arc plasma coating, ion coating and molecular beam epitaxy.

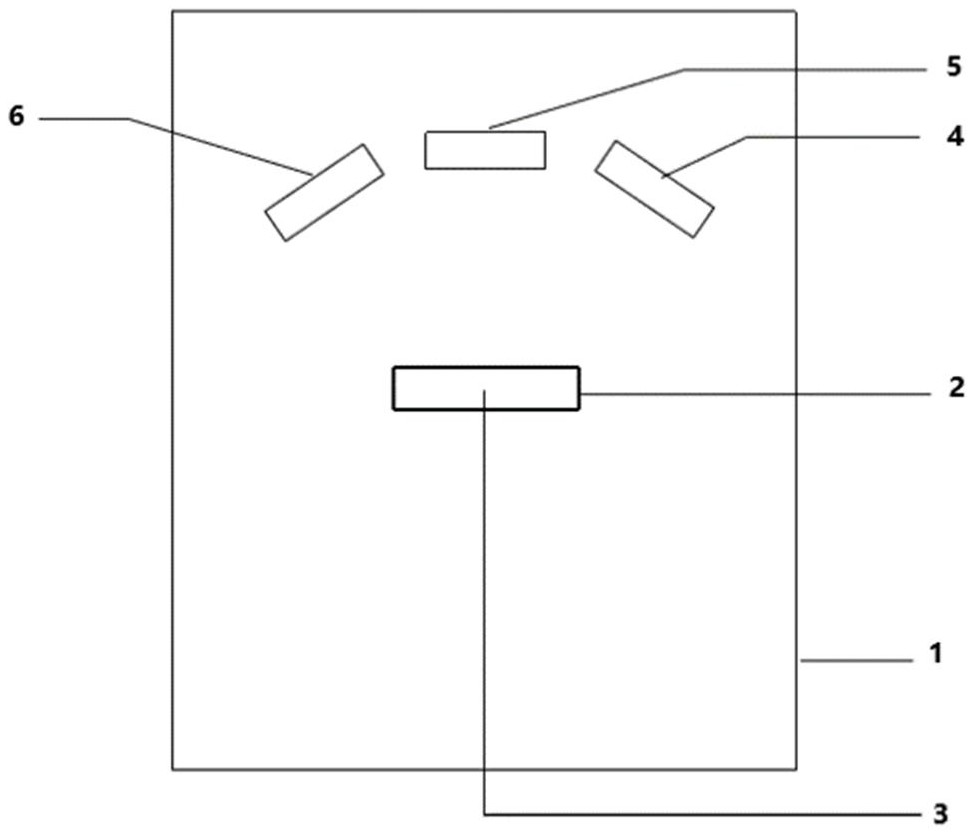

[0060] In one of the embodiments, the physical vapor deposition method is magnetron sputtering coating, and the preparation of the imitation gold alloy by magnetron sputtering coating includes:

[0061] A substrate, a source of Zr, a source of Si, a source of Ni and a source of Cu are provided, a work...

specific Embodiment

[0111] The hardness test method of the present invention is as follows: the model produced by Anton-Paar in Austria is NHT3 nano-indenter to test the hardness of each film, which is configured with a tetrahedral Berkvich indenter, and the indentation depth is set to be 100nm, and the load occurs with the indentation depth Change, and take the average value after testing 5 matrix points for each sample.

[0112] The composition test of the imitation gold alloy of the present invention utilizes the X-ray energy spectrometer (EDX) of FEI Quanta TM 250 FEG to analyze the composition and distribution of the coating. Select an area not less than 30 mm for each sample 2 area, the average value of its constituents is measured.

[0113] Chromaticity value test method of the present invention is as follows: adopt the model that Japanese Konica produces is the L, a, b chromaticity value of test sample of CM-3700A-U desktop spectrometer, the light receiving system selects F2 light source...

Embodiment 1

[0117] This embodiment provides an imitation gold alloy and a preparation method thereof.

[0118] Ni used in this example m Cu 1-m Alloy target, its m=0.10, m is the atomic percentage. The preparation method of imitation gold alloy is as follows:

[0119] 1) Pre-treatment: Put the PET sample into DI water for ultrasonic cleaning for 15 minutes, dry it in a baking oven and put it into the vacuum chamber of the evaporative coating machine. The vacuum chamber is evacuated to 5*10 -5 Pa, heated to 80°C, constant temperature for 15 minutes;

[0120] 2) Deposit the water-soluble peeling layer: in the vacuum chamber, place the PET sample on the sample stage of the resistance evaporation equipment, place the water-soluble water-based ink film material in the evaporation boat, and evacuate to 5.0*10 -5 Pa, depositing a water-based ink peeling layer with a thickness of 30nm on the surface of the PET sample, and taking out the sample after the preparation is completed;

[0121] 3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com