Preparation method of biomedical tissue adhesive

A tissue adhesive and biomedical technology, applied in the field of clinical medicine, can solve the problems of poor adhesion strength, high cytotoxicity, easy to fall off, etc., and achieve good adhesion performance, simple gelation process, and high adhesion strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

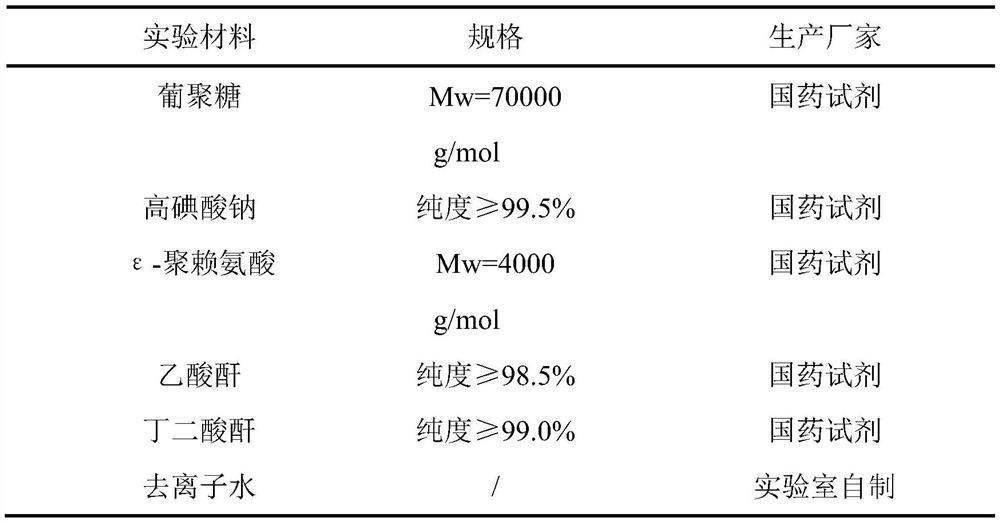

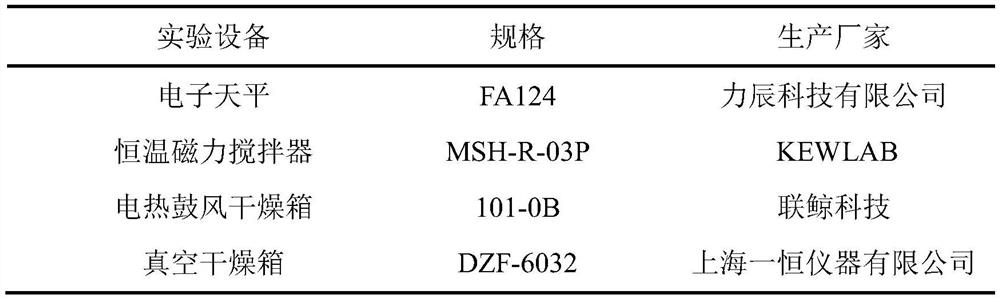

[0023] (1) Prepare an aqueous solution of dextran with a mass fraction of 20%, mix it with an aqueous solution of sodium periodate with a mass fraction of 1%, control the volume ratio of the two to 2:1, and finally stir at a constant temperature at 30°C for 60 minutes; After the reaction is over, dialyze the mixed solution with running water for 18 hours, then further dialyze the mixed solution with deionized water twice for 1.5 hours, and finally obtain aldehyde dextran by drying, and grind it into powder Carry out vacuum drying for 24 hours, and refrigerate and store at -15°C until use;

[0024] (2) Preparation of ε-polylysine aqueous solution with a mass fraction of 25%, diluting acetic anhydride to a concentration of 6% aqueous acetic anhydride with deionized water, mixing the two solutions at a volume ratio of 2:1, at a constant temperature The reaction was carried out at 45°C for 60 minutes under stirring conditions. After the reaction, the reaction solution was purified...

Embodiment 2

[0027] (1) Prepare an aqueous solution of dextran with a mass fraction of 20%, mix it with an aqueous solution of sodium periodate with a mass fraction of 1%, control the volume ratio of the two to 2:1, and finally stir at a constant temperature of 70°C for 60 minutes; After the reaction is over, dialyze the mixed solution with running water for 18 hours, then further dialyze the mixed solution with deionized water twice for 1.5 hours, and finally obtain aldehyde dextran by drying, and grind it into powder Carry out vacuum drying for 24 hours, and refrigerate and store at -15°C until use;

[0028] (2) Preparation of ε-polylysine aqueous solution with a mass fraction of 25%, diluting acetic anhydride to a concentration of 6% aqueous acetic anhydride with deionized water, mixing the two solutions at a volume ratio of 2:1, at a constant temperature The reaction was carried out at 45°C for 60 minutes under stirring conditions. After the reaction, the reaction solution was purified...

Embodiment 3

[0031] (1) Prepare a dextran aqueous solution with a mass fraction of 20%, mix it with a 20% sodium periodate aqueous solution, control the volume ratio of the two to 2:1, and finally stir at 30°C for 60 minutes at a constant temperature; After the reaction is over, dialyze the mixed solution with running water for 18 hours, then further dialyze the mixed solution with deionized water twice for 1.5 hours, and finally obtain aldehyde dextran by drying, and grind it into powder Carry out vacuum drying for 24 hours, and refrigerate and store at -15°C until use;

[0032] (2) Preparation of ε-polylysine aqueous solution with a mass fraction of 25%, diluting acetic anhydride to a concentration of 6% aqueous acetic anhydride with deionized water, mixing the two solutions at a volume ratio of 2:1, at a constant temperature The reaction was carried out at 45°C for 60 minutes under stirring conditions. After the reaction, the reaction solution was purified by dialysis for 24 hours with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com