Silver-carbon electrode material as well as preparation method and application thereof

An electrode material, silver carbon technology, applied in silver carbon electrode material and its preparation, the application field of silver carbon electrode material in seawater desalination device, can solve the problems of poor conductivity, short cycle life of silver electrode, etc., to improve agglomeration , Improve cycle stability, improve the effect of liquid absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The second aspect of the embodiment of the present application provides a method for preparing a silver-carbon electrode material, comprising the following steps:

[0054] S01. Dispersing carbon nanotubes and silver salts in a solvent and ultrasonically treating them to obtain a mixed system;

[0055] S02. Add sodium borohydride aqueous solution to the mixing system, collect the precipitate after the reaction, dry the obtained precipitate and grind it to obtain a powder material;

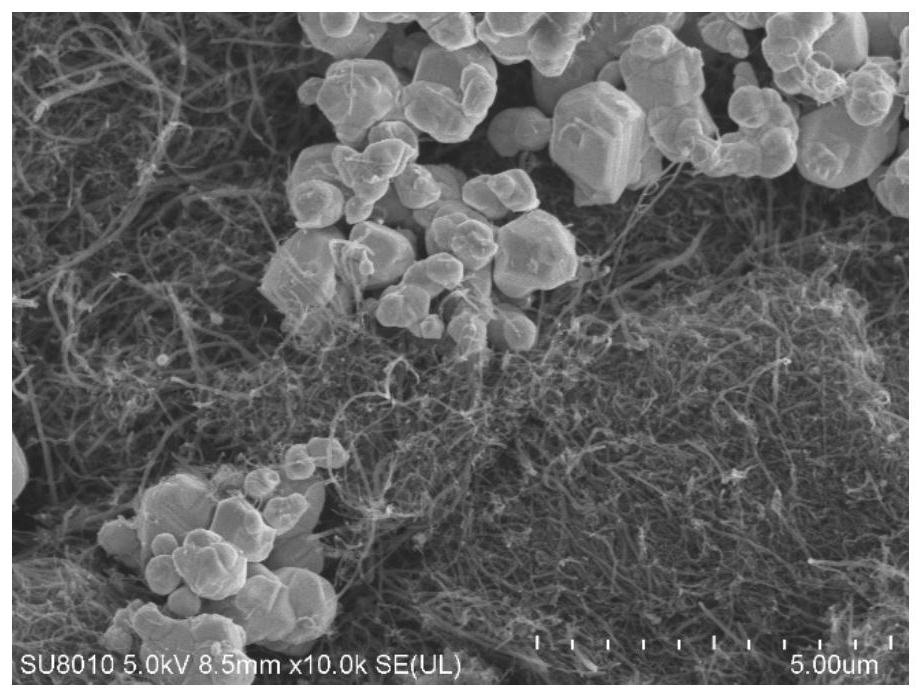

[0056] S03. Annealing the powder material at a temperature of 200-400° C. for 3-8 hours to prepare a silver-carbon electrode material with silver particles loaded on the surface of carbon nanotubes.

[0057] The preparation method of the silver-carbon electrode material provided in the embodiment of the present application uses a wet chemical method to mix carbon nanotubes and silver salts in a solvent, and under the action of a reducing agent, the silver salts are reduced to silver particles...

Embodiment 1

[0083] Preparation of silver carbon materials: silver carbon materials use inorganic carbon nanotubes (CNTs) as carbon source, silver nitrate (AgNO 3 ) as silver source, CNTs and AgNO 3 Add deionized water at a mass ratio of 1:10 for ultrasonication and stirring to make the CNTs uniformly dispersed in water. A 0.75 mol / L sodium borohydride aqueous solution was added dropwise to the dispersed solution to form a gray-black precipitate, and the formed gray-black precipitate was washed 3 times with deionized water and centrifuged. The centrifuged material was transferred to an oven and dried at 80°C for 12 hours. The dried gray-black powder was ground in a mortar for 60 minutes, transferred to a quartz tank, and annealed at 250°C for 5 hours to obtain a silver-carbon material.

[0084] Grind the prepared silver-carbon material in a mortar for 30 minutes, mix it with activated carbon and polyvinylidene fluoride in a mass ratio of 8:1:1 to obtain the first mixture, then add the fir...

Embodiment 2

[0092] The basic steps are the same as in Example 1, the difference is: CNTs and AgNO 3 The molar ratio was set to 1:20.

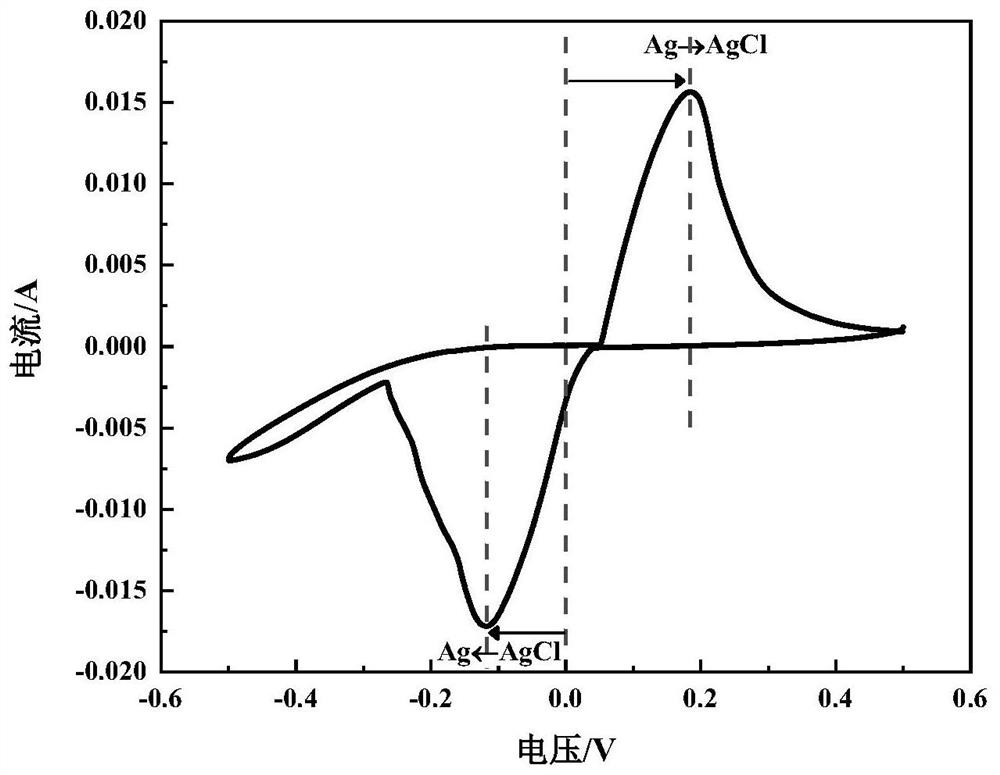

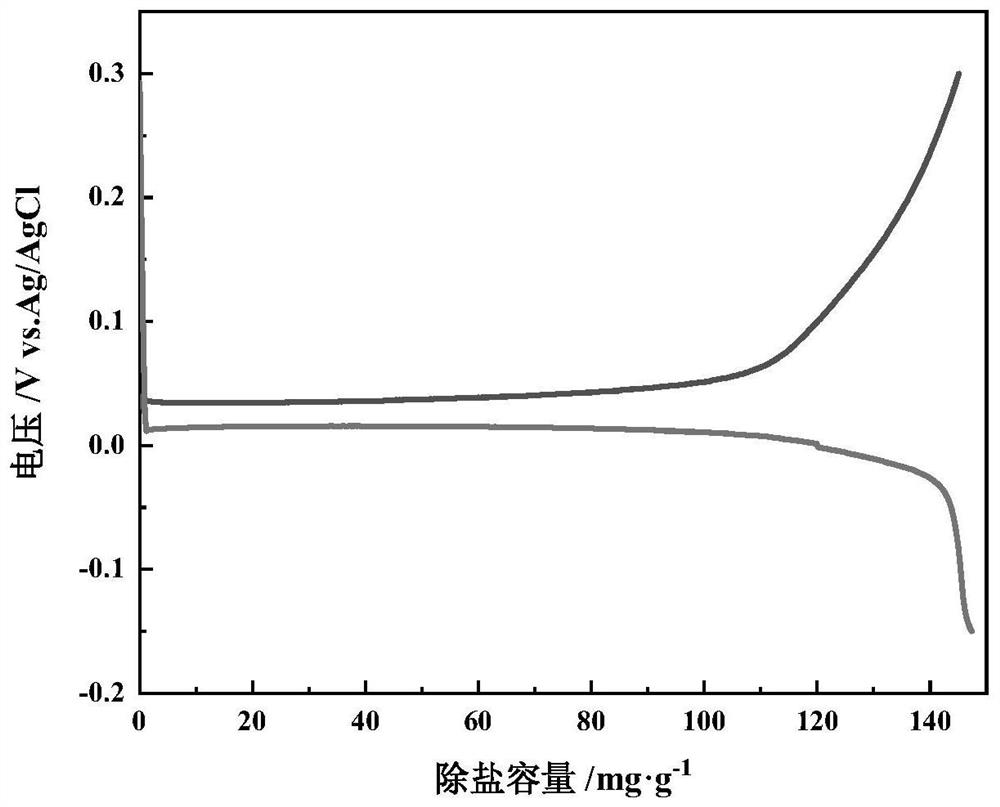

[0093] The performance test of the silver carbon electrode prepared in Example 2 was carried out. When other conditions remain unchanged, only change the CNTs and AgNO 3 The test results show that the electrochemical performance of the electrode is good, the oxidation peak and reduction peak shown in the CV diagram are obvious, the symmetry is good, the electrode also has high stability, and the initial desalination amount is 201mg / g , after 150 cycles, the desalination capacity was stable at 75mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com