IGBT device and manufacturing method thereof

A manufacturing method and device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as large current, achieve the effects of reducing emission efficiency, accelerating recombination speed, and reducing hole volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

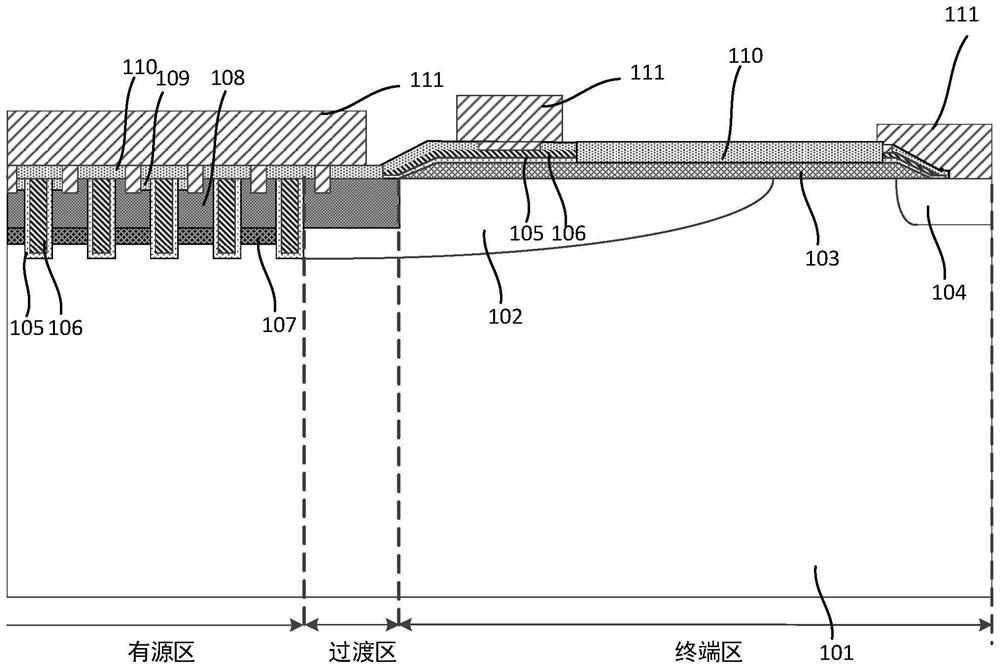

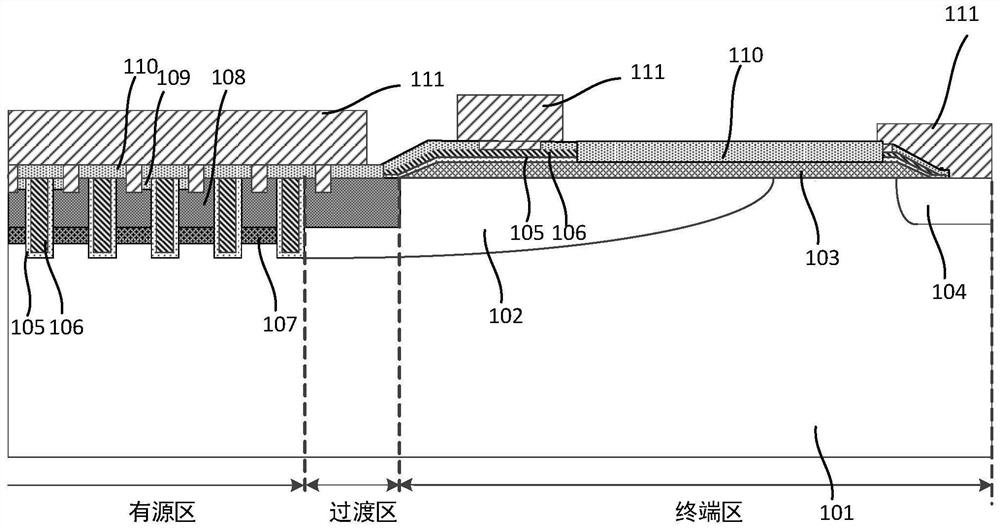

[0046] IGBT devices can be divided into three regions, namely active region, transition region and termination region. When the IGBT device is turned on, the back P-type collector begins to inject holes into the drift region of the IGBT device. During the turn-off period of the IGBT device, it is necessary to extract all the electrons and holes injected into the drift region during the conduction period, and the electrons are removed from the IGBT device. The back side of the IGBT device flows out, and the holes flow out from the front side of the IGBT device. The holes in the active area can directly flow out from the openings on the front of the active area, but there is no current channel on the front of the terminal area. The holes in the terminal area mainly flow out from the openings in the transition area, which will lead to current in the transition area. The problem of concentration, the transitional concentration of local current, leads to a local temperature rise, w...

Embodiment 2

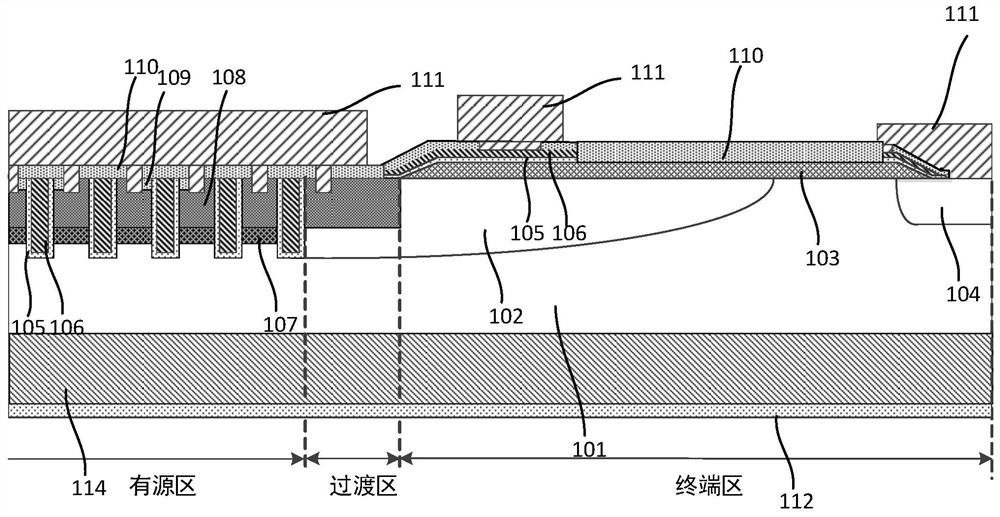

[0065] like Figure 5 As shown, this embodiment provides an IGBT device, the IGBT device includes: a substrate 101, the substrate 101 includes a first main surface and a second main surface opposite, and the first main surface is formed with an IGBT device The front structure of the IGBT device includes an active region, a transition region and a terminal region; a first helium ion defect layer 113' and a second helium ion defect layer 113, the first helium ion defect layer 113' is formed in the In the second main surface of the active region, the second helium ion defect layer 113 is formed in the second main surface of the transition region and the terminal region, and the defect density of the first helium ion defect layer 113' is less than The defect density of the second helium ion defect layer 113; the collector region, formed on the second main surface of the substrate; the collector region 112, formed on the second main surface of the substrate 101; the first conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com