Preparation method of carbon fiber/rare earth oxide nanowire mixed reinforcement, as well as obtained material and application of carbon fiber/rare earth oxide nanowire mixed reinforcement

A rare earth oxide and carbon fiber preform technology, applied in the direction of rare earth metal oxide/hydroxide, carbon fiber, lanthanide oxide/hydroxide, etc. Weak carbon fiber bonding, environmental pollution and other problems, to achieve the effect of improving the interface bonding and mechanical properties, the preparation process is simple and controllable, and the reaction temperature is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing a carbon fiber / rare earth oxide nanowire mixed reinforcement, specifically comprising the following steps:

[0033] 1) Put the carbon fiber prefabricated body in an atmosphere protection furnace and heat-treat it at 500-1000°C for 2-5 hours, then clean it with deionized water by ultrasonic vibration, and dry it at 80-120°C for later use.

[0034] 2) Prepare the dry rare earth salt into an aqueous solution, add a surfactant dropwise, stir with a magnetic stirrer at 30-50°C for 30 minutes, and at the same time add a sodium hydroxide solution dropwise to adjust the pH value to 10-13 to obtain a reaction solution, wherein The concentration of rare earth ions is 0.1-0.6 mol / L, the concentration of active agent is 0.05-0.15 mol / L, and the concentration ratio of rare earth ions to sodium hydroxide is 1:2-1:5.

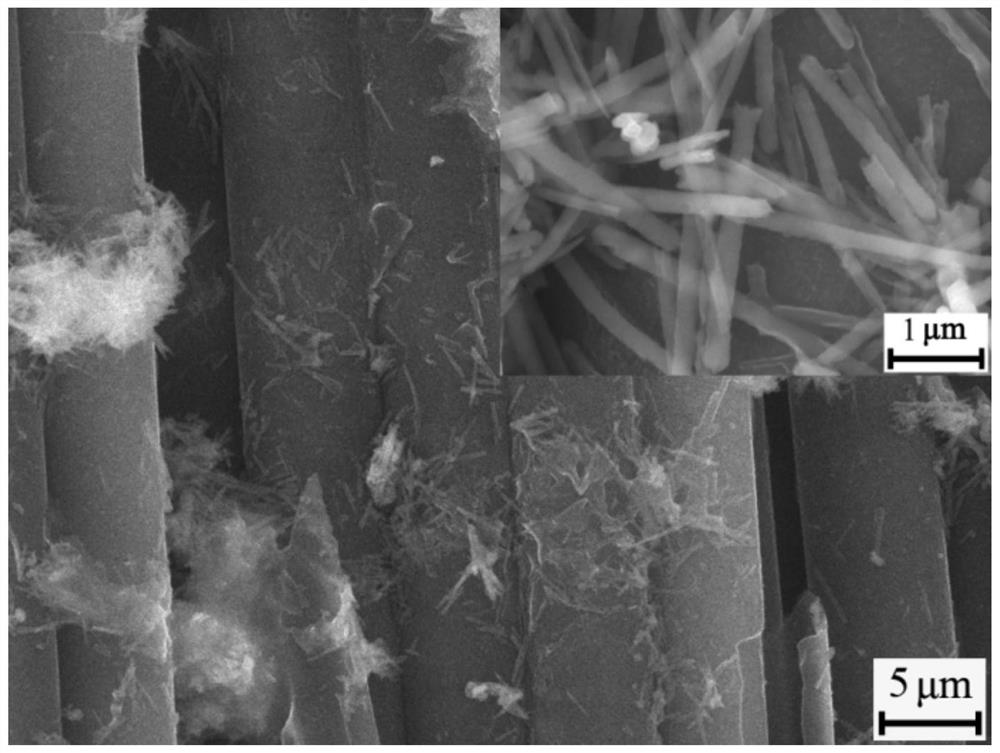

[0035] 3) Put the reaction solution and the treated carbon fiber prefabricated body in the reaction kettle, perform in-situ synthesis of rare ear...

Embodiment 1

[0040] A method for preparing a carbon fiber / rare earth oxide nanowire mixed reinforcement, comprising the following steps:

[0041] 1) Arrange the carbon fiber in a vacuum atmosphere protection furnace and heat-treat it at 500°C for 5 hours, then wash it with deionized water and ultrasonic vibration, and dry it at 80°C for later use.

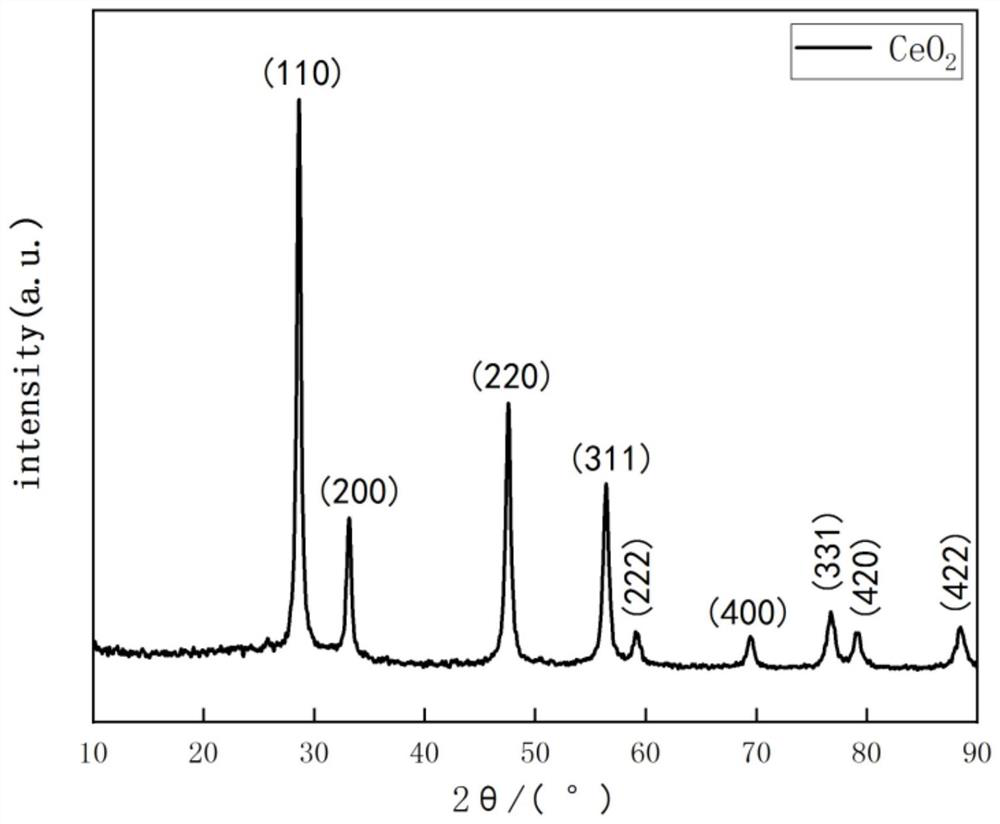

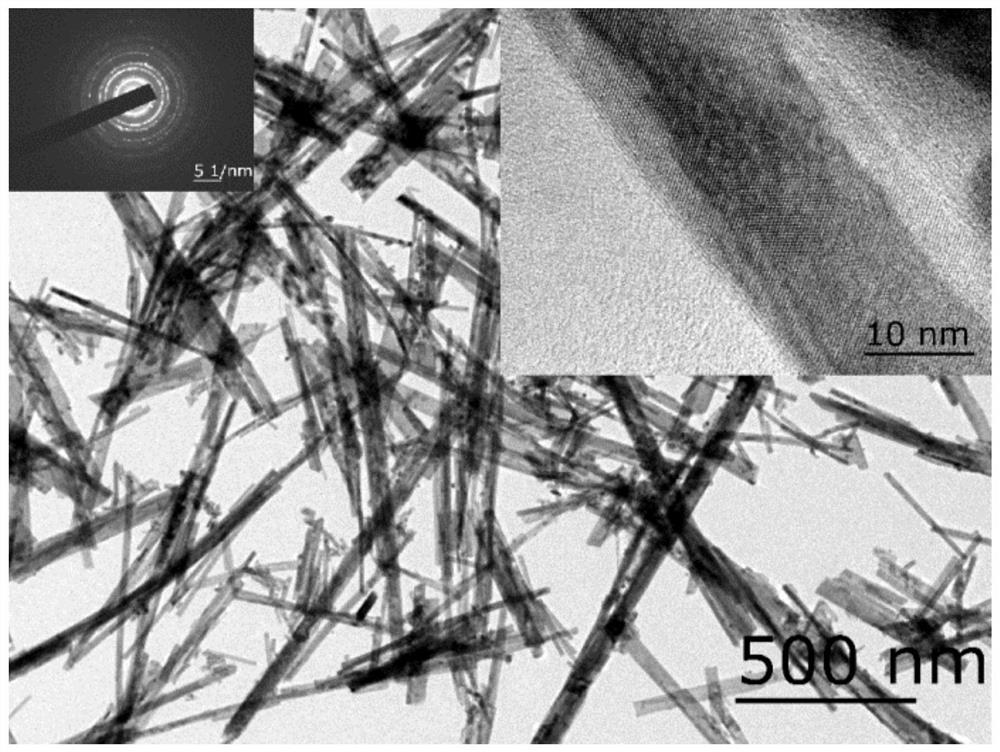

[0042] 2) Prepare dry cerium chloride into an aqueous solution, add cetyltrimethylammonium bromide dropwise, stir with a magnetic stirrer for 30 minutes at 30°C, and simultaneously add sodium hydroxide solution dropwise to adjust the pH value to 10 to obtain The reaction solution, wherein the concentration of cerium ions is 0.1mol / L, the concentration of cetyltrimethylammonium bromide is 0.05mol / L, and the concentration ratio of cerium to sodium hydroxide is 1:2.

[0043] 3) Arrange the reaction liquid and the treated carbon fiber in the reaction kettle, perform in-situ synthesis of cerium oxide nanowires after ultrasonic oscillation for 30 min...

Embodiment 2

[0047] A method for preparing a carbon fiber / rare earth oxide nanowire mixed reinforcement, comprising the following steps:

[0048] 1) Set the density to 0.20g / cm 3 The carbon fiber integral felt was placed in an atmosphere protection furnace and heat-treated at 700 °C for 4 hours, then cleaned with deionized water ultrasonic vibration, and dried at 90 °C for use.

[0049] 2) Prepare the dry lanthanum chloride into an aqueous solution, add ethylene glycol dropwise, stir with a magnetic stirrer at 40°C for 30 minutes, and at the same time add sodium hydroxide solution dropwise to adjust the pH value to 11 to obtain a reaction solution, in which the concentration of lanthanum ions The concentration of ethylene glycol is 0.3mol / L, the concentration of ethylene glycol is 0.1mol / L, and the concentration ratio of cerium to sodium hydroxide is 1:3.

[0050] 3) Put the reaction solution and the treated carbon fiber integral felt in the reaction kettle, perform in-situ synthesis of l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com