Bonding pretreatment method for aluminum alloy workpiece

A technology for aluminum alloys and workpieces, which is applied in the field of thermal control adhesive bonding pretreatment of aluminum alloy skins for space operations, and can solve problems such as low hemispherical emissivity and low solar light absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

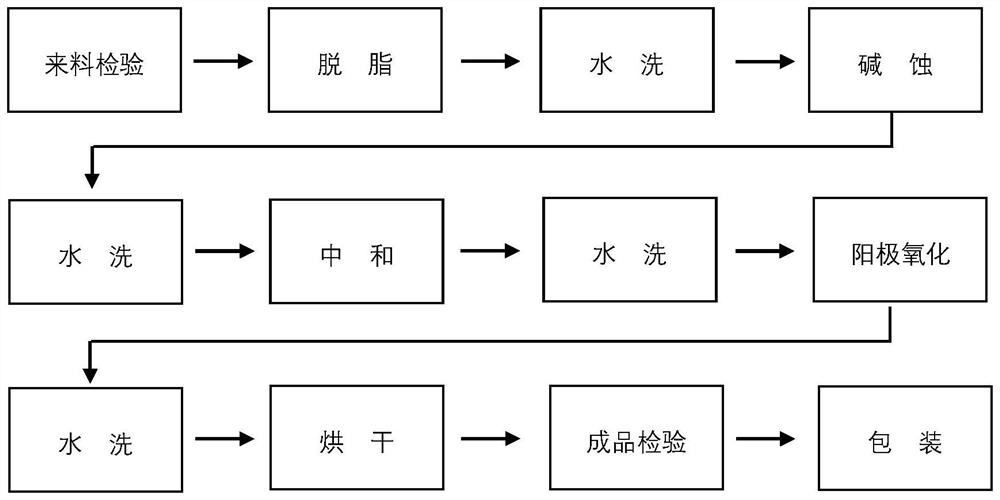

Image

Examples

Embodiment 1

[0031] Example 1: 6 series aluminum alloy

[0032] (1) Workpiece pre-processing:

[0033] Degreasing, water washing, alkali etching, water washing, neutralization, and water washing are carried out sequentially to the aluminum alloy workpiece; wherein, in the step (1), the degreasing is ultrasonic degreasing, and the formula of the degreasing solution used during the degreasing treatment is: Na 3 PO 4 30g / L, NaOH 10g / L and NaOH 2 SO 4 14g / L; the degreasing treatment temperature is 55°C, and the degreasing treatment time is 7min.

[0034] Wherein, in the step (1), the formula of the alkali etching solution used in the alkali etching treatment is: NaOH 75g / L; the alkali etching treatment temperature is 50°C, and the alkali etching treatment time is 30s.

[0035] Wherein, in the step (1), the formula of the neutralizing solution adopted during the neutralization treatment is: HNO 3 230g / L, H 2 o 2 100g / L; the neutralization treatment temperature is 20°C, and the neutral...

Embodiment 2

[0042] Example 2: 5 series aluminum alloy

[0043] (1) Workpiece pre-processing:

[0044] Degreasing, water washing, alkali etching, water washing, neutralization, and water washing are carried out sequentially to the aluminum alloy workpiece; wherein, in the step (1), the degreasing is ultrasonic degreasing, and the formula of the degreasing solution used during the degreasing treatment is: Na 3 PO 4 30g / L, NaOH 10g / L and NaOH 2 SO 4 14g / L; the degreasing treatment temperature is 50°C, and the degreasing treatment time is 7min.

[0045] Wherein, in the step (1), the formula of the alkali etching solution used in the alkali etching treatment is: NaOH 75g / L; the alkali etching treatment temperature is 50°C, and the alkali etching treatment time is 30s.

[0046] Wherein, in the step (1), the formula of the neutralizing solution adopted during the neutralization treatment is: HNO 3 230g / L, H 2 o 2 100g / L; the neutralization treatment temperature is 20°C, and the neutral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com