A reactive ion etching method and device

A technology of reactive ion etching and equipment, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of small plasma kinetic energy, large equipment volume, difficulty reaching the bottom of deep holes or deep grooves, etc., to improve selectivity, The effect of increasing the etching rate and improving the etching morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

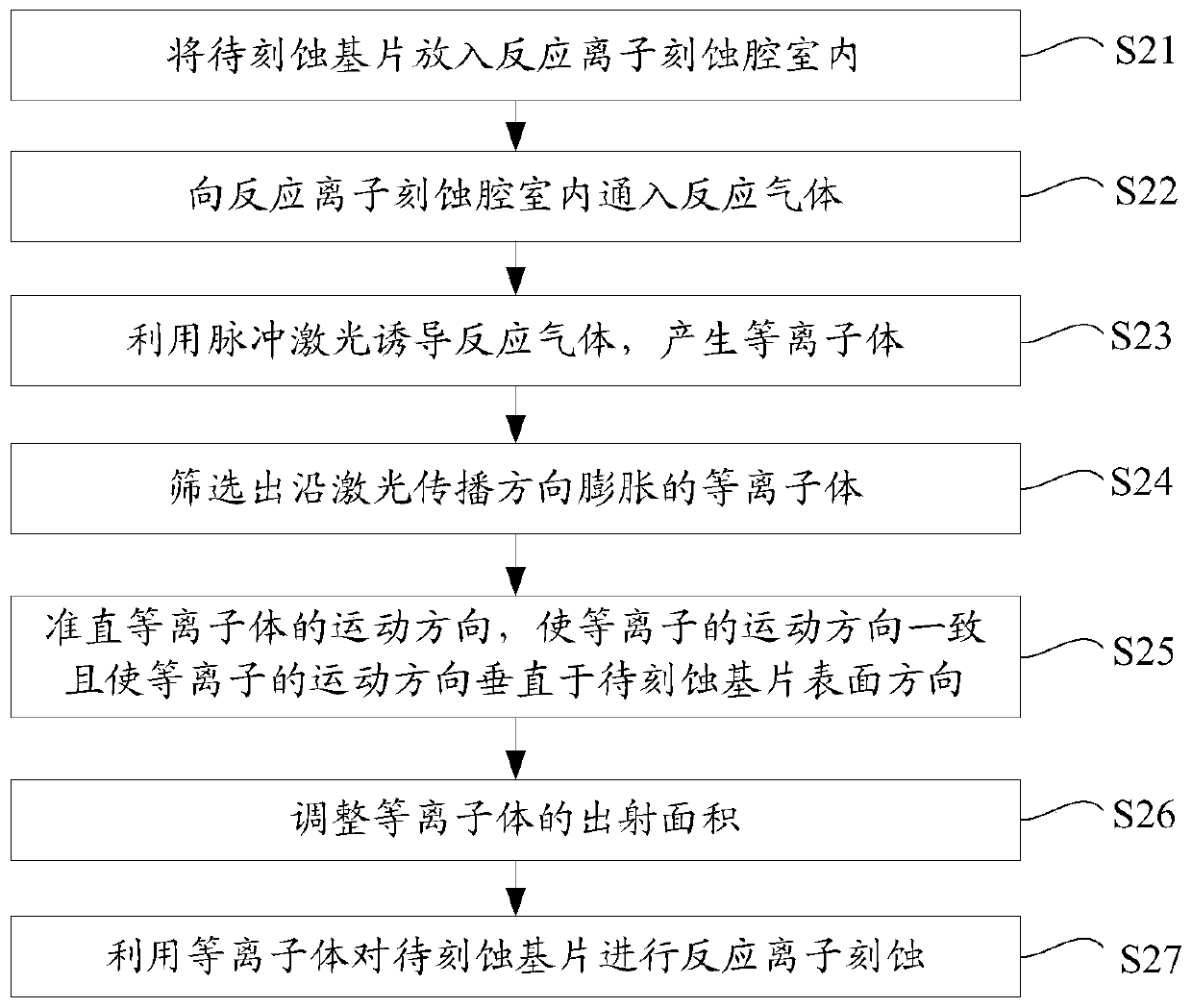

[0046] Specific embodiments of the present application will be described in detail below in conjunction with the accompanying drawings.

[0047] Firstly, the specific implementation of the reactive ion etching equipment for implementing the reactive ion etching method provided in this application will be introduced.

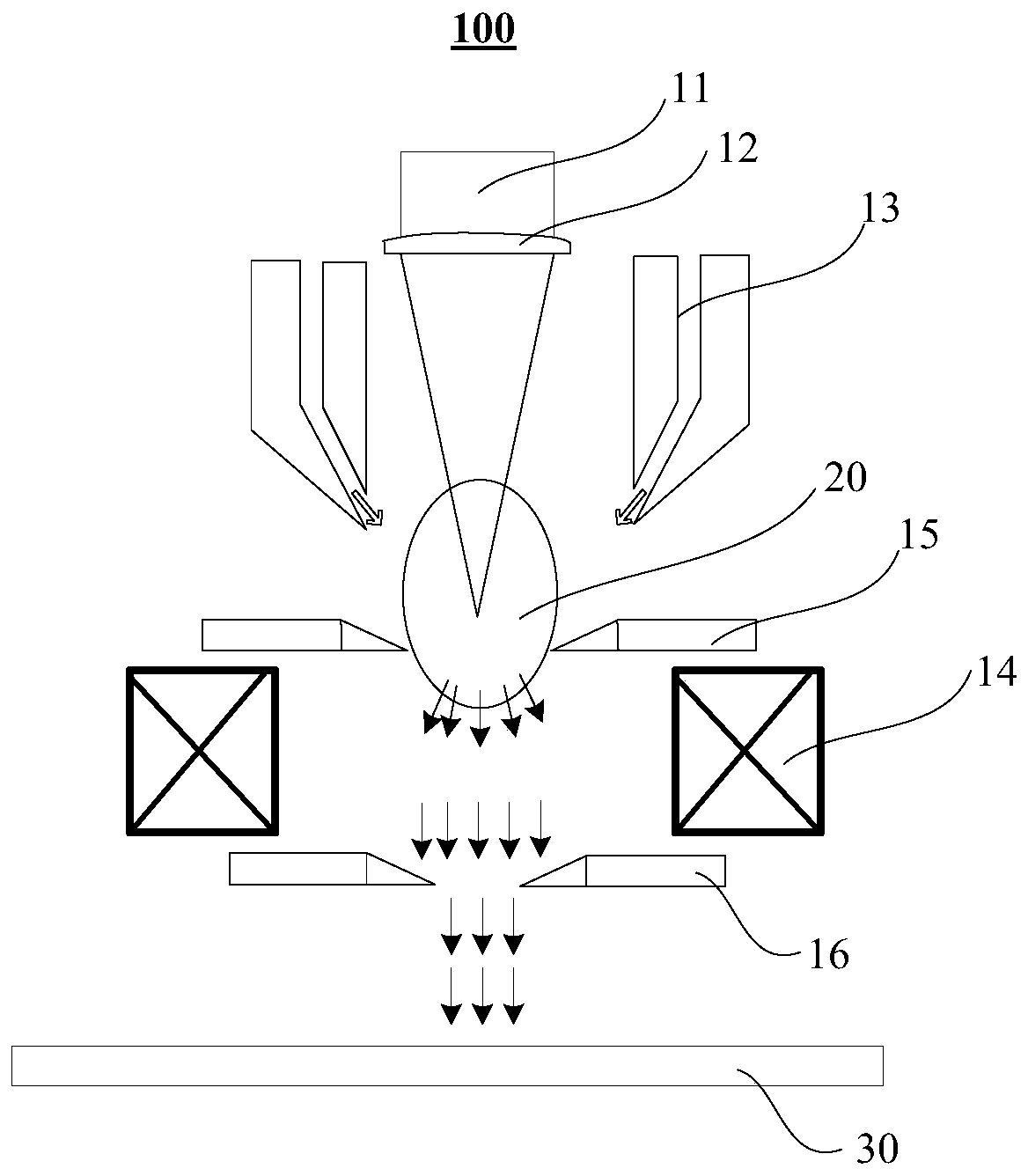

[0048] See figure 1 . The reactive ion etching equipment 100 includes: a pulsed laser source 11 , a focusing lens 12 , a reactive gas nozzle 13 and an ion deflection magnetic lens 14 .

[0049] Among them, the pulsed laser source 11 is used to generate pulsed laser; as a specific embodiment of the present application, in order to improve the ionization degree of the reaction gas, the density of the generated plasma and the initial kinetic energy of the plasma, the pulsed laser source 11 can be a high-frequency pulse laser source. As an example, the frequency of the pulsed laser source 11 may be greater than 10 kHz. As an example, the pulsed laser source 11 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com