Air combustion laser plasma decomposition device

A technology of air combustion and plasma, applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as low safety, gas poisoning, and insufficient maximum temperature of plasma flames, and achieve enhanced ionization and higher temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail through the drawings and examples below. Through these descriptions, the features and advantages of the present invention will become more apparent.

[0061] The word "exemplary" is used exclusively herein to mean "serving as an example, embodiment, or illustration." Any embodiment described herein as "exemplary" is not necessarily to be construed as superior or better than other embodiments. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

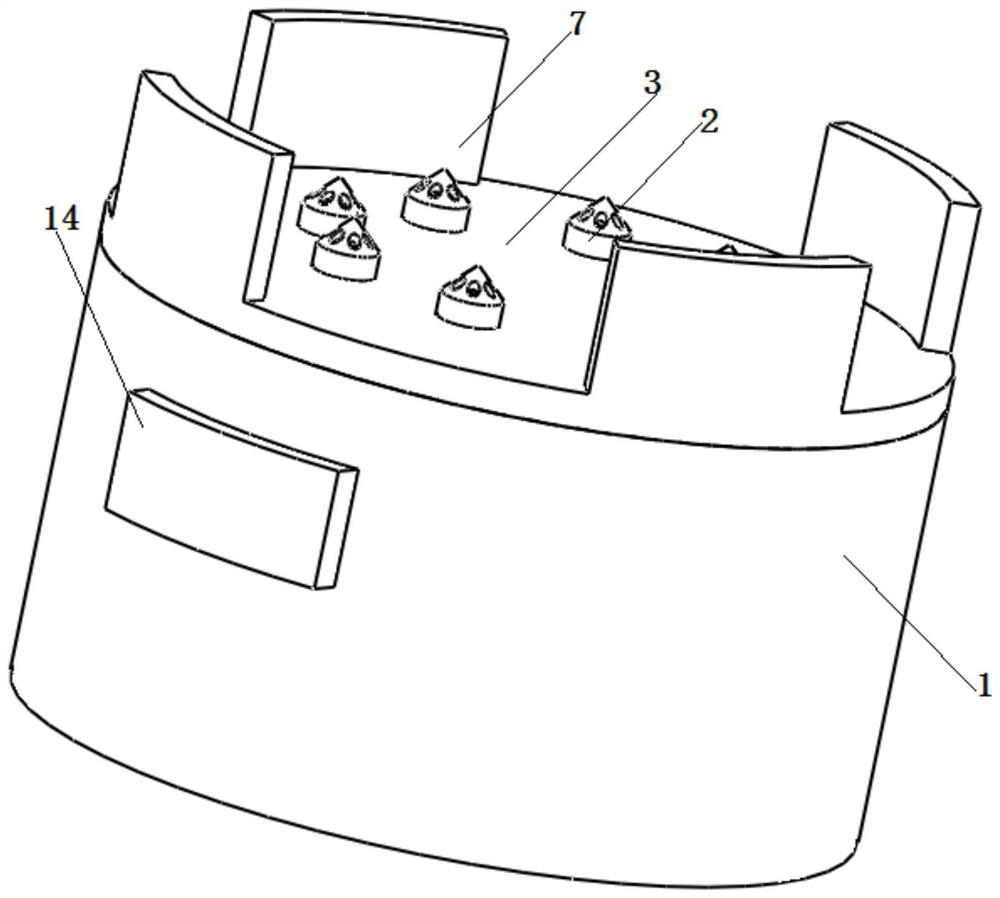

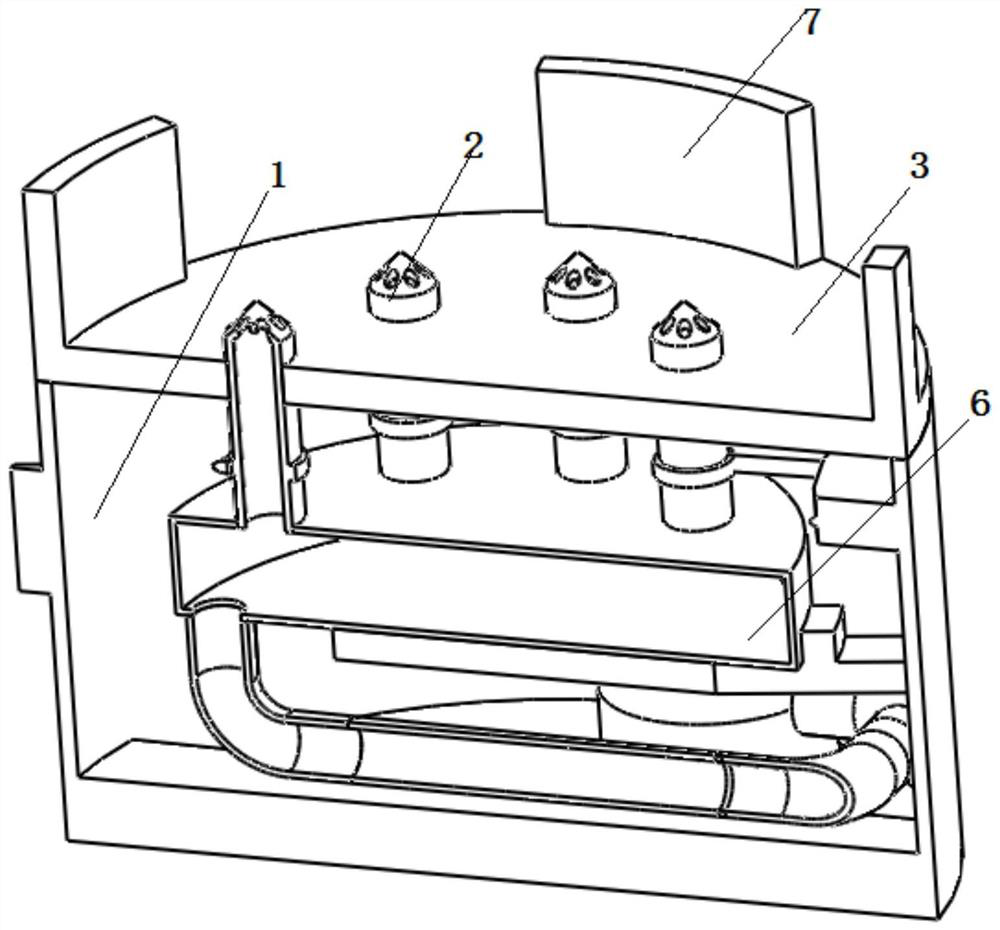

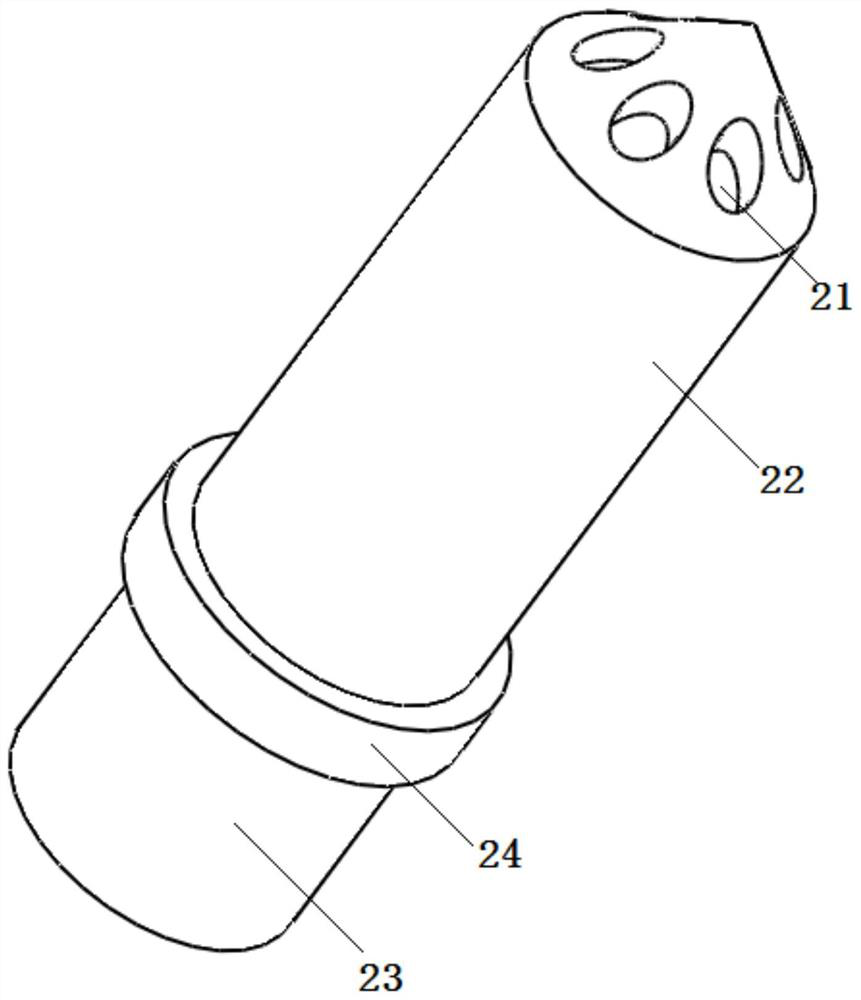

[0062] According to the air combustion laser plasma decomposition device provided by the present invention, such as figure 1 and figure 2As shown in , the device includes a furnace body 1 and an ionizing rod 2, the furnace body is preferably in a regular shape such as a cylinder or a cuboid, and the ionizing rod 2 is in the shape of a rod, preferably a hollow rod-shaped structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com