Double-layer Hot Wire Coating Process for Diamond Coating of Ladder Composite Tool

A diamond coating and composite cutting tool technology, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., to achieve the effect of increasing density, ensuring growth current, and stably placing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

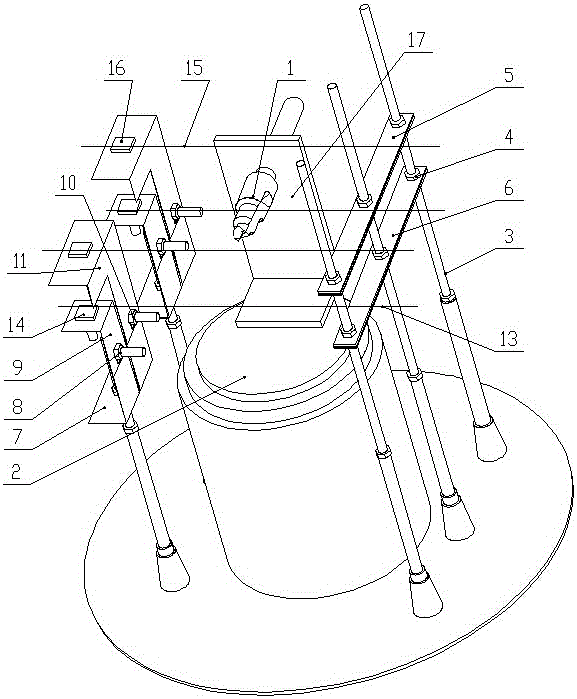

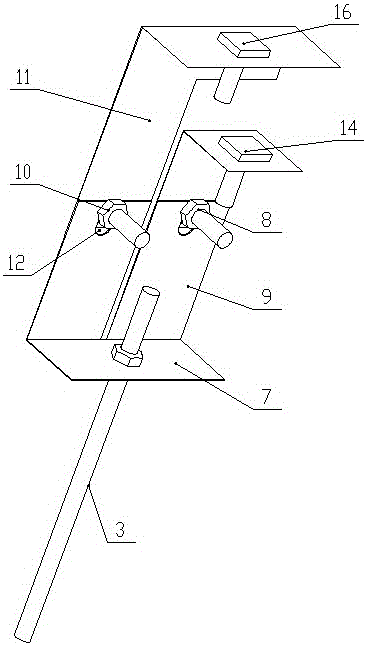

[0025] Such as figure 1 and figure 2 Shown, the double-layer hot wire coating process that is used for step composite tool diamond coating of the present invention comprises the following steps:

[0026] (1) Put the stepped compound tool 1 into the mixed solution of hydrochloric acid and nitric acid for pretreatment by ultrasonic cleaning, so as to ensure that every layer of the drilling part can be cleaned;

[0027] (2) Assemble a double-layer heating wire adjustment mechanism in the reaction chamber;

[0028] (3) Carbonize the hot wire of the double-layer hot wire adjustment mechanism;

[0029] (4) Place the stepped compound tool 1 in the double-layer heating wire adjustment mechanism;

[0030] (5) Carry out nucleation and growth treatment on the surface of the cutter head in the reaction chamber, wherein the pressure during nucleation is -99.6Kpa, the power of the hot wire is maintained at 750-850W, the bias current is 0.8A, and the bias current power is maintained at 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com