Low-yield-ratio, anti-seismic, high-toughness and corrosion-resistant gas shielded welding wire for building structure and application thereof

A technology of gas-shielded welding wire and low yield ratio, applied in welding equipment, welding medium, welding/cutting medium/material, etc., to achieve the effect of ensuring atmospheric corrosion resistance, improving low-temperature impact toughness, and good comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The composition and mass percentage (Wt.%) of the welding wire in this embodiment are: C 0.092, Si 0.42, Mn 1.80, S0.0017, P 0.0049, Ni 1.85, Mo 0.40, Cu 0.45, Co 0.21, Ti 0.030, O 0.0092 , the balance being Fe and other unavoidable impurities.

[0031] The welding wire is smelted in a 0.5t electric furnace, and processed into a welding wire with a diameter of Φ1.2mm after forging, drawing and copper plating.

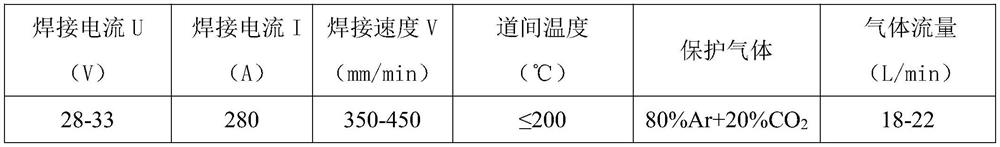

[0032] The gas shielded welding welding test of the welding wire obtained in this embodiment adopts 80% Ar+20% CO 2 For protection, the welding process parameters are as follows:

[0033] Table 1 welding process parameters

[0034]

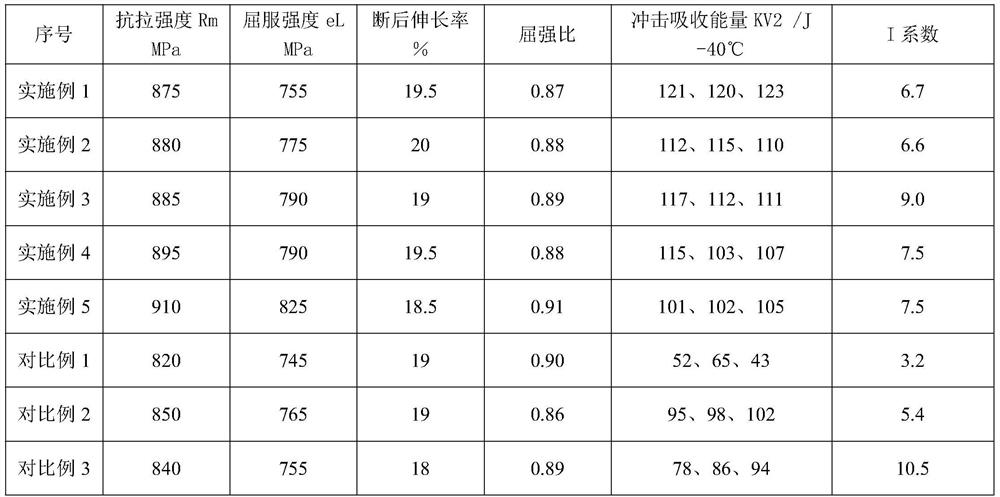

[0035] See Table 2 for the tensile properties, yield ratio, impact toughness and atmospheric corrosion resistance of the welding wire of this embodiment.

Embodiment 2

[0037] The difference between this embodiment and Example 1 is: the composition and mass percentage (Wt.%) of the welding wire in this embodiment are: C 0.084, Si 0.51, Mn 1.90, S 0.0020, P 0.0061, Ni 2.30, Mo 0.51, Cu 0.48, Co0.23, Ti 0.034, O 0.0089, the balance is Fe and other unavoidable impurities. The welding wire preparation and welding test methods are the same as in Example 1. The tensile properties, yield ratio, impact toughness, and atmospheric corrosion resistance of the welding wire in this example are shown in Table 2.

Embodiment 3

[0039]The difference between this embodiment and embodiment 1 is: the composition and mass percentage (Wt.%) of the welding wire in this embodiment are: C 0.086, Si 0.50, Mn 1.68, S 0.0042, P 0.0045, Ni 2.39, Mo 0.41, Cu 0.35, Co0.24, Ti 0.049, O 0.0099, the balance is Fe and other unavoidable impurities. The welding wire preparation and welding test methods are the same as in Example 1. The tensile properties, yield ratio, impact toughness, and atmospheric corrosion resistance of the welding wire in this example are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com