A catalyst for hydrotreating hydrocarbon oil and a method of hydrotreating hydrocarbon oil using the catalyst

A technology for hydroprocessing and catalysts, which is applied in the fields of hydrocarbon oil treatment, chemical instruments and methods, catalyst activation/preparation, etc. It can solve the problems of high dispersibility of inorganic oxide components and insufficient improvement of catalytic performance, etc. , to achieve long catalyst life and improve economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

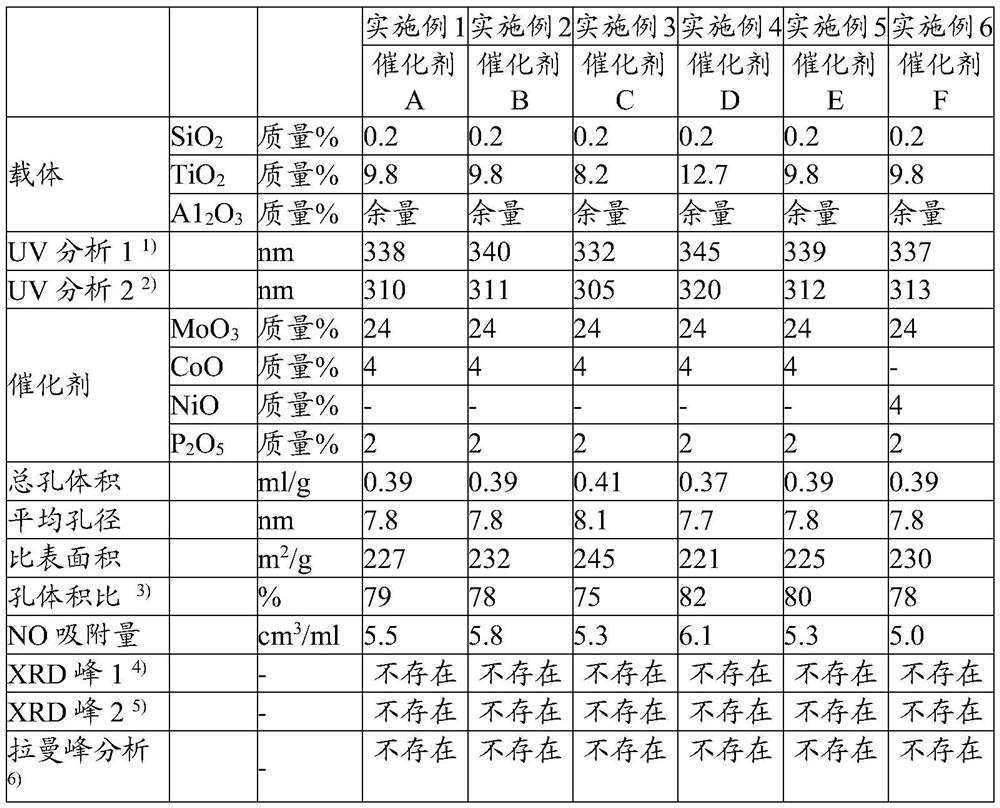

Embodiment 1

[0099] Add aluminum sulfate solution (as Al 2 0 3 8.1% by mass), sodium aluminate solution (as Al 2 0 3 21.6% by mass) and titanyl sulfate solution (with TiO 2 13.6% by mass) and water glass and mixed to prepare a silica-titania-alumina hydrate gel (silica / titania / alumina mass ratio: 0.2 / 9.8 / 90.0). After separating the hydrate from the solution, rinse with warm water and remove impurities, peptize by adding an organic acid, heat knead with a kneader to adjust the water content to 67%, extrude and mold, and in air at 600°C Calcined for 1.5 hours to obtain a silica-titania-alumina support.

[0100] The carrier is impregnated with an aqueous solution containing molybdenum trioxide, basic cobalt carbonate, phosphoric acid and citric acid monohydrate (0.1 times the molar amount relative to the amount of molybdenum and cobalt), so that the carrier contains 24% by mass of molybdenum trioxide, 4% by mass of cobalt oxide and 2% by mass of phosphorus oxide. After drying at 120°C f...

Embodiment 2

[0102] Catalyst B was prepared by the same method as in Example 1, except that the impregnation solution to be added in Example 1 was used in an amount of 0.1 times molar and 0.2 times molar relative to the total moles of molybdenum and cobalt, respectively. Organic additives of citric acid monohydrate and polyethylene glycol (average molecular weight: 200). Table 4 shows the physical properties and chemical composition of Catalyst B.

Embodiment 3

[0104] Catalyst C is prepared by the same method as in Example 1, except that the addition amount of titanyl sulfate is changed in Example 1 to prepare silica-titania-alumina hydrate gel (silicon dioxide / titania / Alumina mass ratio: 0.2 / 8.2 / 91.6). Table 4 shows the physical properties and chemical composition of Catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com