Anti-aging rubber material and preparation method thereof

A rubber material, aging-resistant technology, applied in the field of rubber composite materials, can solve the problems of migration, internal and external structural defects of rubber, poor compatibility of rubber matrix, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

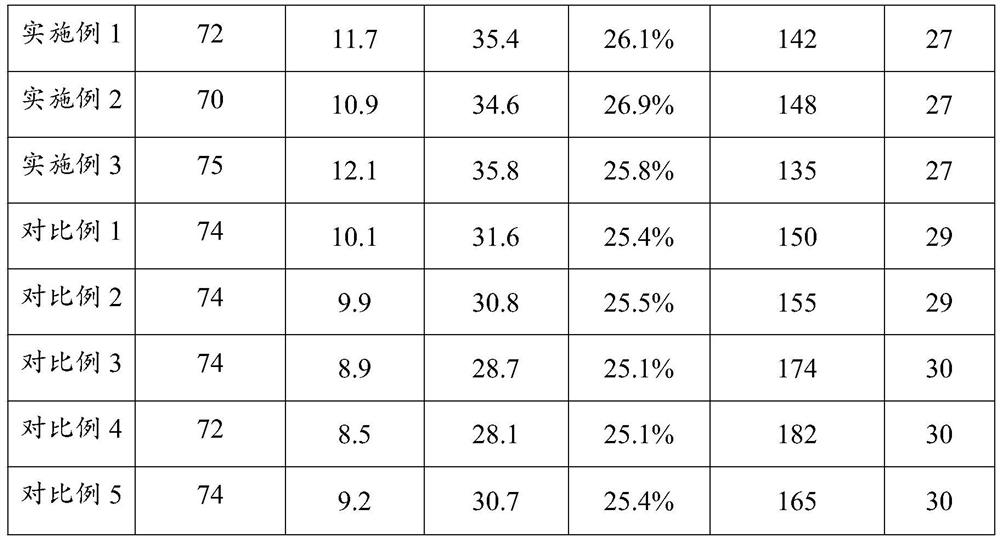

Embodiment 1

[0030] A kind of anti-aging rubber material, the raw material of the rubber material is made of the following components by weight through high temperature vulcanization:

[0031] 55 parts of styrene-butadiene rubber, 35 parts of butadiene rubber, 10 parts of chlorinated polyethylene, 5 parts of zinc oxide, 3 parts of stearic acid, 15 parts of zinc borate, 25 parts of aluminum hydroxide, 45 parts of modified reinforcing anti-aging agent, 3 parts Part of sulfur, 1.2 parts of N-cyclohexyl-2-benzothiazole sulfenyl CZ, 0.5 parts of dibenzothiazole disulfide DM, 0.3 parts of zinc diethyldithiocarbamate EZ, 1 part of microcrystalline Wax, 1 part polyethylene glycol PEG-4000;

[0032] The preparation method of modified reinforcing antioxidant comprises the following steps:

[0033] S1. Add 8 mL of coupling agent bis(3-triethoxysilylpropyl) tetrasulfide to 40 mL of absolute ethanol, and ultrasonically shake for 1 hour at a temperature of 55°C to undergo a pre-hydrolysis reaction to o...

Embodiment 2

[0041] Basically the same as Example 1, the difference is that the anti-aging rubber material is made of the following components by weight after high-temperature vulcanization:

[0042] 50 parts of styrene-butadiene rubber, 40 parts of butadiene rubber, 10 parts of chlorinated polyethylene, 5 parts of zinc oxide, 2 parts of stearic acid, 15 parts of zinc borate, 30 parts of aluminum hydroxide, 40 parts of modified reinforcing anti-aging agent, 4 parts 1.5 parts of sulfur, 1.5 parts of N-cyclohexyl-2-benzothiazole sulfenyl CZ, 1.0 parts of dibenzothiazole disulfide DM, 1.5 parts of microcrystalline wax, 1.5 parts of polyethylene glycol PEG-4000;

[0043] The preparation method of modified reinforcing antioxidant comprises the following steps:

[0044] S1. Add 8 mL of coupling agent bis(3-triethoxysilylpropyl) tetrasulfide to 40 mL of absolute ethanol, and ultrasonically shake for 2 hours at a temperature of 50°C to undergo a pre-hydrolysis reaction to obtain a coupling agent p...

Embodiment 3

[0047] Basically the same as Example 1, the difference is that the anti-aging rubber material is made of the following components by weight after high-temperature vulcanization:

[0048] 60 parts of styrene-butadiene rubber, 30 parts of butadiene rubber, 15 parts of chlorinated polyethylene, 8 parts of zinc oxide, 4 parts of stearic acid, 15 parts of zinc borate, 20 parts of aluminum hydroxide, 50 parts of modified reinforcing anti-aging agent, 3 parts Part of sulfur, 1.2 parts of N-cyclohexyl-2-benzothiazole sulfenyl CZ, 0.5 parts of dibenzothiazole disulfide DM, 0.3 parts of zinc diethyldithiocarbamate EZ, 1.5 parts of microcrystalline Wax, 1.0 parts of polyethylene glycol PEG-4000;

[0049] The preparation method of modified reinforcing antioxidant comprises the following steps:

[0050] S1. Add 8mL of coupling agent bis(3-triethoxysilylpropyl)tetrasulfide to 40mL of absolute ethanol, and ultrasonically shake for 1.5h at a temperature of 50°C to undergo a prehydrolysis rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com