Artificial bone material without loss of elastic modulus as well as preparation method and application of artificial bone material

A technology of elastic modulus and artificial bone, applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of clinical application and low elastic modulus, achieve strong industrial application potential, convenient operation, and avoid bone healing slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention discloses a preparation method of an artificial bone material with no loss in elastic modulus, the steps are as follows:

[0034] a. Preparation of porogen: Use a pulverizer to pulverize the large-sized porogen, and use screens of different sizes to control the particle size of the porogen to 50 μm-200 μm;

[0035] b. Sulfonation treatment: Use 200-mesh, 400-mesh, and 600-mesh sandpaper to smooth the surface of the polyetheretherketone sample, and ultrasonically ultrasonicate the sample in ethanol, acetone, and deionized water for 15 minutes, and then immerse the naturally dried sample in a mass Soak in concentrated sulfuric acid with a fraction of 90%-98% for 30-180s;

[0036] c. Cold pressing: at room temperature, apply an external pressure of 2-6 MPa to the surface of the sulfonated polyether ether ketone material, so that the porogen spread under the material is embedded on the surface;

[0037] d. Leaching: Place the sulfonated sample in deionized wa...

Embodiment 1

[0040] Embodiment 1 A kind of artificial bone material without loss of elastic modulus and its preparation method

[0041] 1) Preparation of pure PEKK sample:

[0042] Use 200-mesh, 400-mesh, and 600-mesh sandpaper in turn to polish the surface of the polyether ketone ketone sample, and ultrasonically clean the sample in ethanol, acetone, and deionized water for 15 minutes, and then dry it naturally;

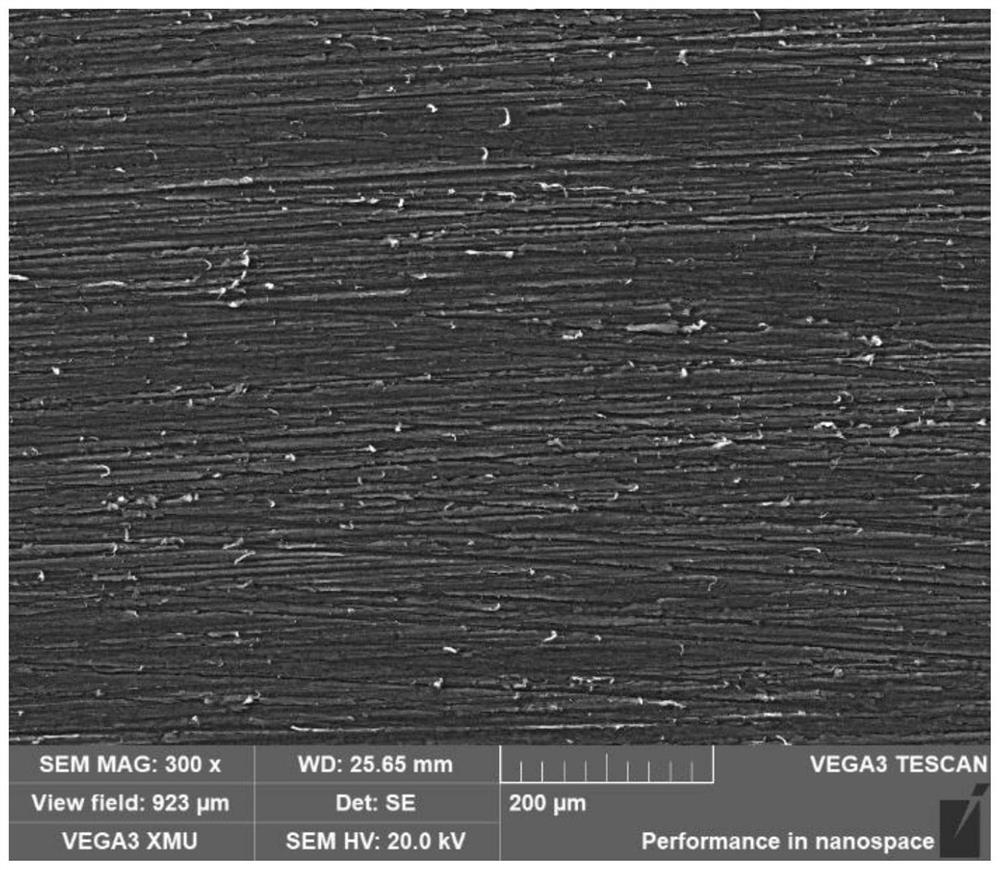

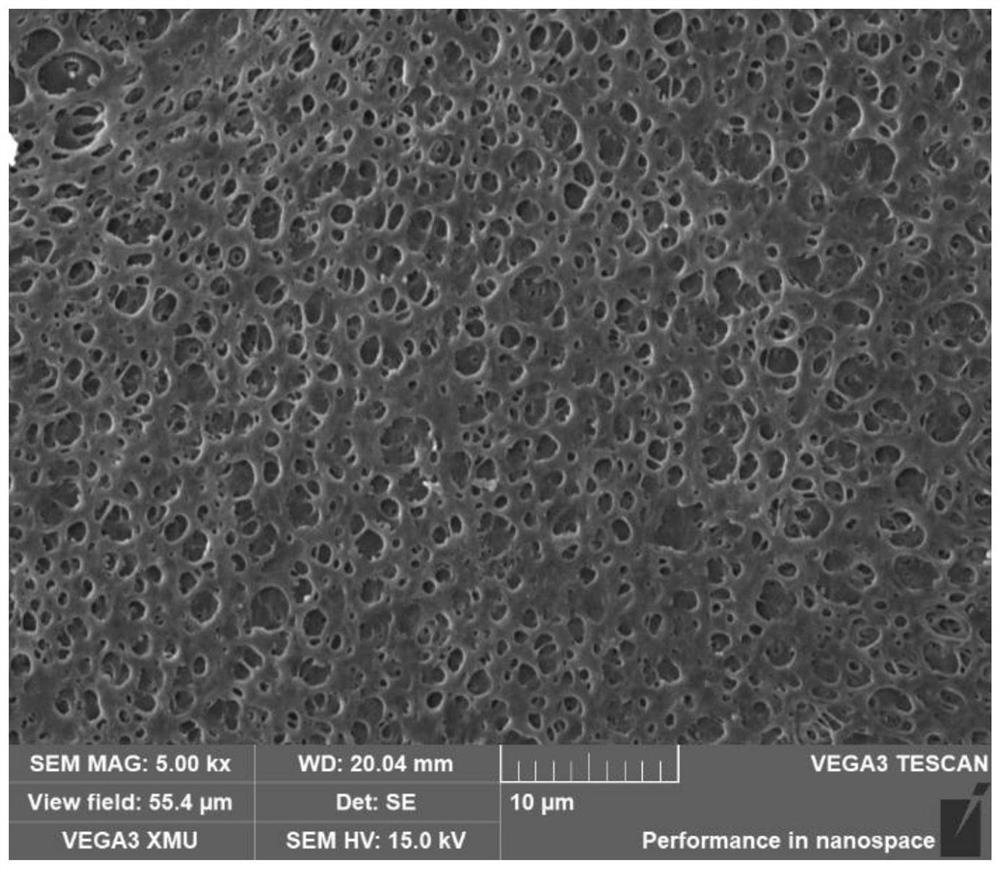

[0043] from figure 1 It can be seen from the scanning electron microscope image of the surface of the pure PEKK sample after polishing that the surface of the pure PEKK sample is smooth and flat, and no pore structure is observed.

[0044] 2) Preparation of sulfonated SPEKK samples:

[0045] Use 200-mesh, 400-mesh, 600-mesh sandpaper in turn to smooth the surface of the polyether ketone ketone sample, ultrasonicate the sample in ethanol, acetone, and deionized water for 15 minutes, and then immerse the naturally dried sample in a mass fraction of 90%-98 % concentrated sulfuri...

Embodiment 2

[0059] Embodiment 2 A kind of artificial bone material without loss of elastic modulus and its preparation method

[0060] 1) Preparation of a porous polyether ketone ketone material with no loss in elastic modulus:

[0061] a. Preparation of porogen: Use a pulverizer to pulverize the large-sized porogen sodium chloride, and use screens of different sizes to sieve out sodium chloride with a porogen size of 10 μm-50 μm.

[0062] b. Sulfonation treatment: use 200-mesh, 400-mesh, and 600-mesh sandpaper to smooth the surface of the polyetheretherketone sample, and ultrasonically ultrasonicate the sample in ethanol, acetone, and deionized water for 15 minutes, and then immerse the naturally dried sample in a mass Soak in concentrated sulfuric acid with a fraction of 90%-98% for 120s;

[0063] c. Cold pressing: at room temperature, an external pressure of 4 MPa is applied to the surface of the sulfonated polyetheretherketone material, so that the porogen spread under the material i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com