Co-production process for desalted intestinal mucosa protein powder and heparinoid

A technology of intestinal mucosa and protein powder is applied in the field of co-production process of desalted intestinal mucosa protein powder and heparinoid, which can solve problems such as environmental protection and production and operation problems, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

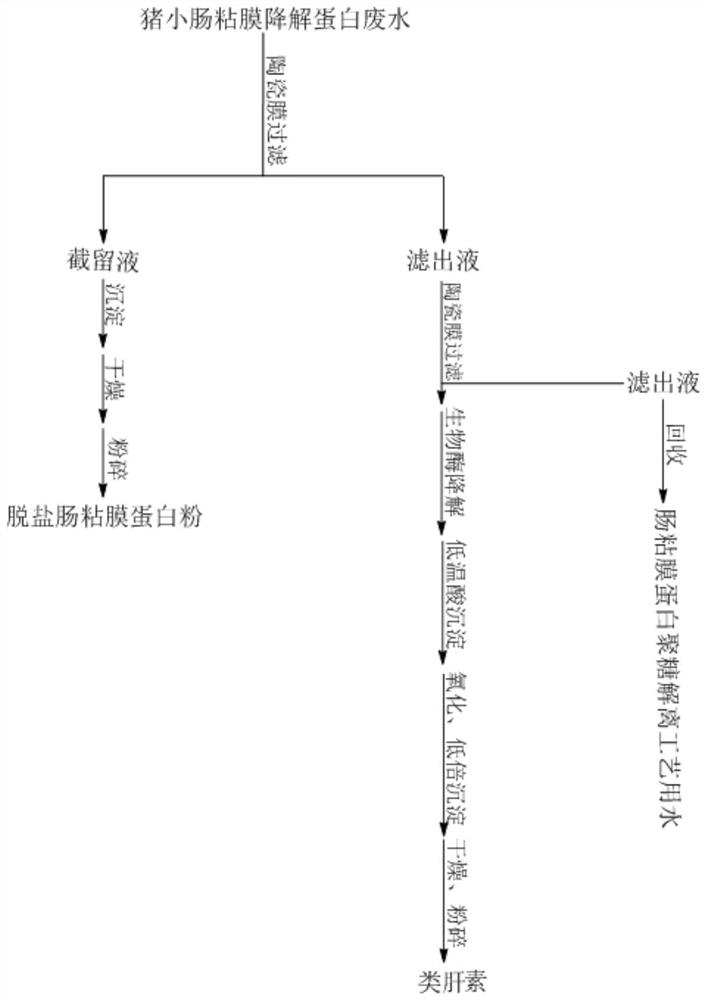

[0018] A co-production process of desalted intestinal mucosal protein powder and heparin, comprising the following characteristic steps:

[0019] The process steps of desalted intestinal mucosal protein powder are:

[0020] S1. Collect 500L of salt-containing protein waste water in the production process of crude heparin sodium as raw material liquid, transfer the raw material liquid to the turnover box, filter it through the ceramic membrane with a pore size of 10KD, and add purified water to the turnover tank during the filtration process Keep the volume of the raw material liquid unchanged, and detect the change of the salinity of the raw material liquid at the same time. When the detected salinity of the raw material liquid drops below 0.1%, no longer add purified water to the turnover tank, and continue to filter and concentrate until the volume of the raw material liquid is 100L is the retentate, which is concentrated desalted intestinal mucosal protein solution;

[002...

Embodiment 2

[0039] A co-production process of desalted intestinal mucosal protein powder and heparin, comprising the following characteristic steps:

[0040] The process steps of desalted intestinal mucosal protein powder are:

[0041] S1. Collect 500L of saline protein waste water from the production process of crude heparin sodium as the raw material liquid, transfer the raw material liquid to the turnover box, filter it through a ceramic membrane with a pore size of 30KD, and add purified water to the turnover tank during the filtration process Keep the volume of the raw material liquid constant, and detect the salinity change of the raw material liquid at the same time. When the detected salinity of the raw material liquid drops below 0.1%, no longer add purified water to the turnover tank, and continue to filter and concentrate until the volume of the raw material liquid is 100L is the retentate, which is concentrated desalted intestinal mucosal protein solution;

[0042]S2. Add 400...

Embodiment 3

[0057] A co-production process of desalted intestinal mucosal protein powder and heparin, comprising the following characteristic steps:

[0058] The process steps of desalted intestinal mucosal protein powder are:

[0059] S1. Collect 500L of saline protein waste water from the production process of crude heparin sodium as the raw material liquid, transfer the raw material liquid to the turnover box, filter it through a ceramic membrane with a pore size of 30KD, and add purified water to the turnover tank during the filtration process Keep the volume of the raw material liquid unchanged, and detect the change of the salinity of the raw material liquid at the same time. When the detected salinity of the raw material liquid drops below 0.1%, no longer add purified water to the turnover tank, and continue to filter and concentrate until the volume of the raw material liquid is 100L is the retentate, which is concentrated desalted intestinal mucosal protein solution;

[0060] S2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com