Room-temperature electro-deposition preparation method of copper foil with high crystal face preferred orientation

A technology of preferred orientation and crystal plane orientation, applied in electroforming, electrolytic process, electrolytic components, etc., can solve the problems of reducing the conductivity of copper foil, impairing grain growth, impairing mechanical properties, etc., achieving simple formula, easy operation, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

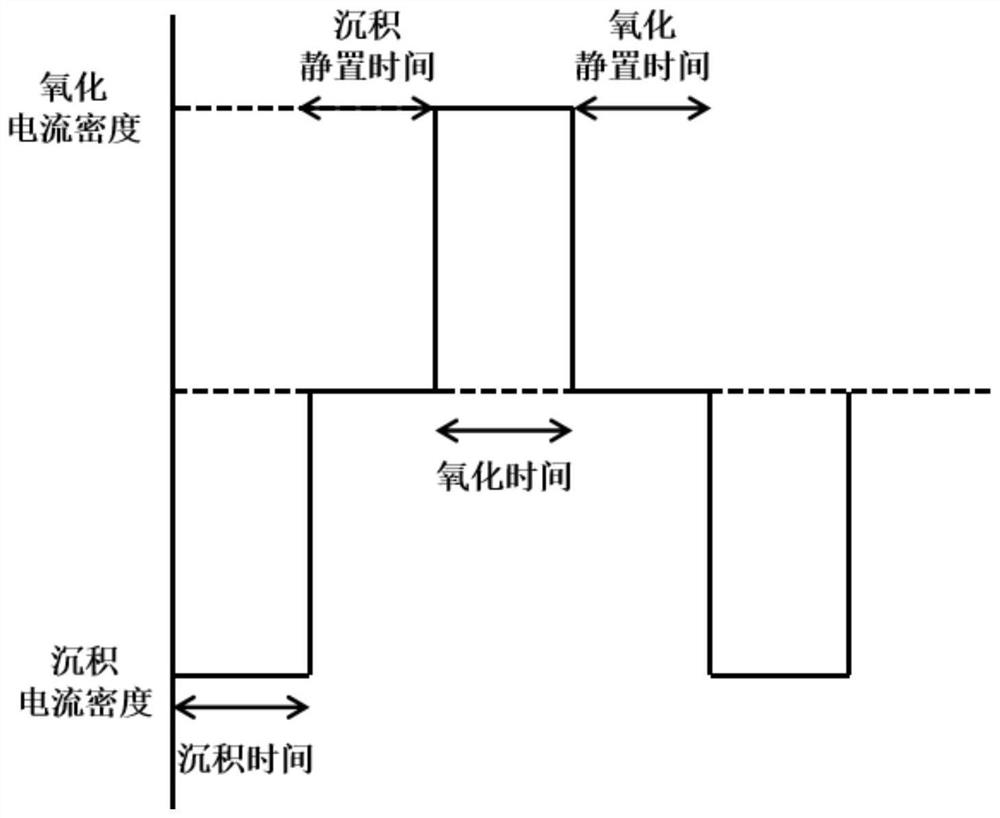

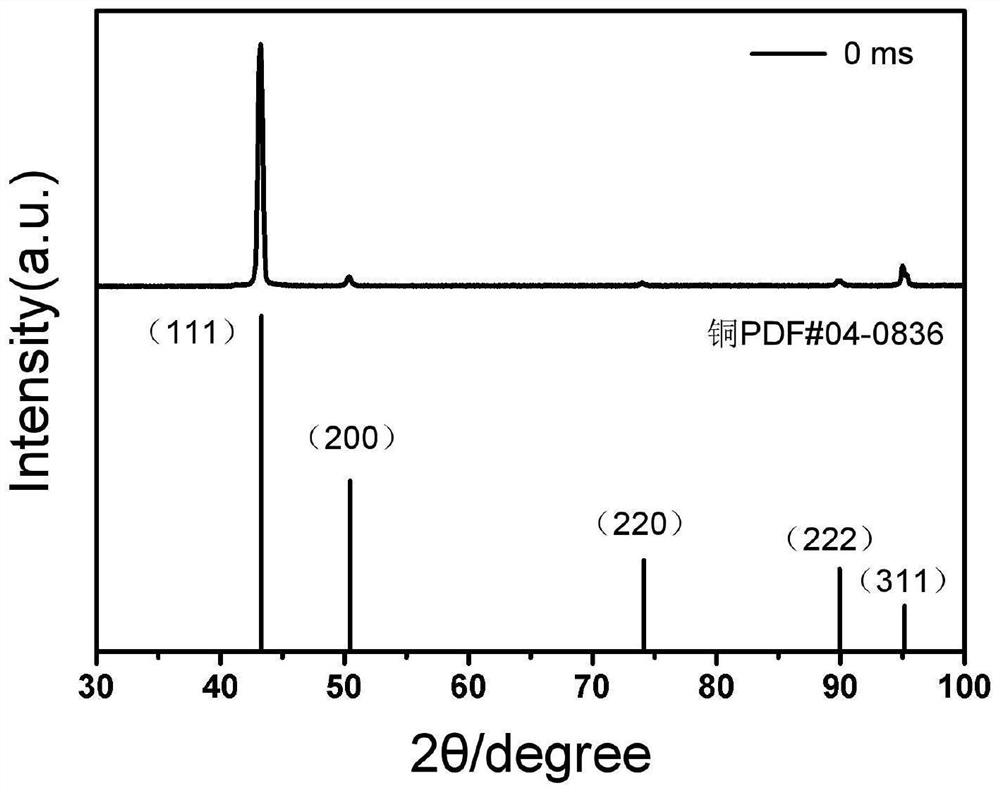

[0029] A copper foil with preferred crystal plane orientation, the preferred crystal plane is copper (111) plane. Prepared by pulse current deposition method, such as figure 1 As shown, the steps are as follows:

[0030] Step 1): weighing a certain mass of copper sulfate pentahydrate with a purity of 98%, adding a certain mass of deionized water, fully stirring and heating to completely dissolve it, and preparing a 250g / L copper sulfate solution. Draw a small amount of concentrated sulfuric acid 0.9-1.1.

[0031] Step 2): Take 50-100mL of the above-mentioned copper sulfate solution, wash the copper sheet with a size of 2*2cm and a purity of 99.99% with dilute sulfuric acid, deionized water, and absolute ethanol, and wash the copper sheet with a size of 1*1.5cm and a purity of 99% The titanium sheet is submerged in absolute ethanol for 5 minutes, and the copper sheet and titanium sheet are composed of an anode and a cathode, and immersed in the above-mentioned copper sulfate ...

Embodiment 2

[0034] A copper foil with preferred crystal plane orientation, the preferred crystal plane is copper (111) plane.

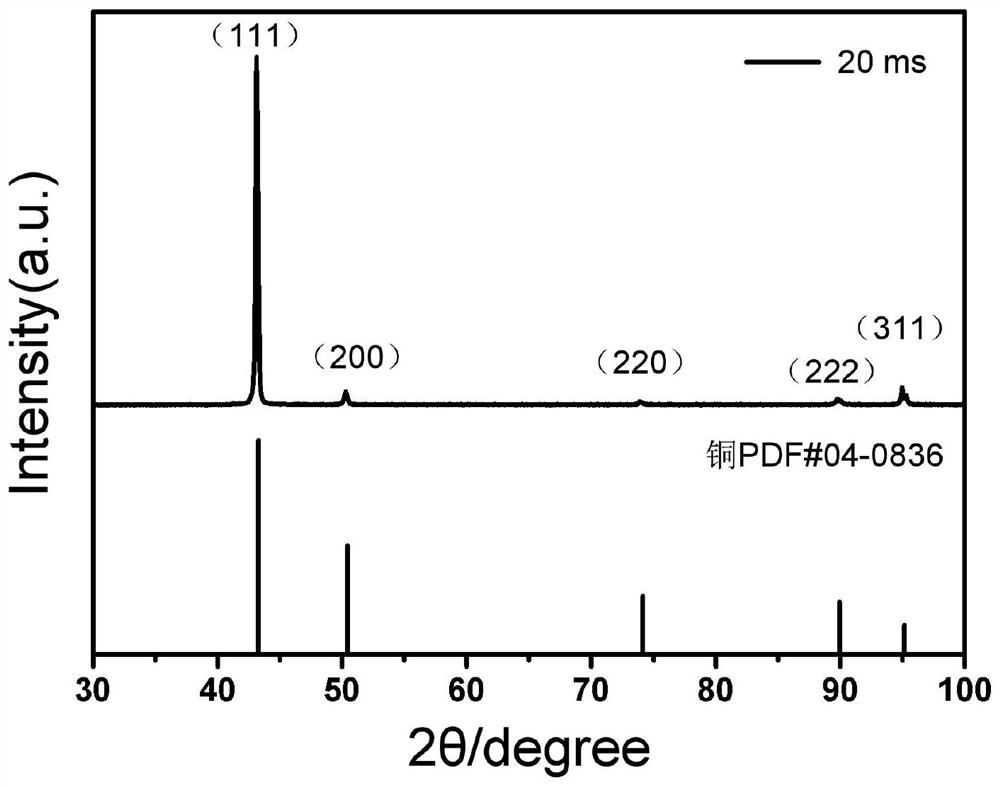

[0035] Compared with Example 1, the difference in the preparation steps is that only the deposition resting time is changed to 20 ms, step 3) obtains copper foil Q2 with preferred orientation of copper (111) crystal plane, and its orientation is stronger than that of copper foil Q1. The XRD pattern of copper foil Q2 matte surface is as follows image 3 shown.

Embodiment 3

[0037] A copper foil with no crystal face preferred orientation.

[0038] Compared with Example 1, the difference in the preparation steps is that only the deposition resting time is changed to 60 ms, step 3) obtains the copper foil Q3 without the preferred orientation of the crystal plane. The XRD pattern of copper foil Q3 matte surface is as follows Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com