Shear strength improving composition, shear strength improving agent and preparation method and application of shear strength improving agent

The technology of a composition and a cutting agent is applied in the preparation of organic compounds, the composition of drilling holes, the preparation of carboxylic acid amides, etc., which can solve the problems of low cutting force performance, and achieve increased hardness and modulus, simple formula, High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The shear raising agent obtained by the preparation method of the present application has excellent high-temperature stability and high cutting efficiency.

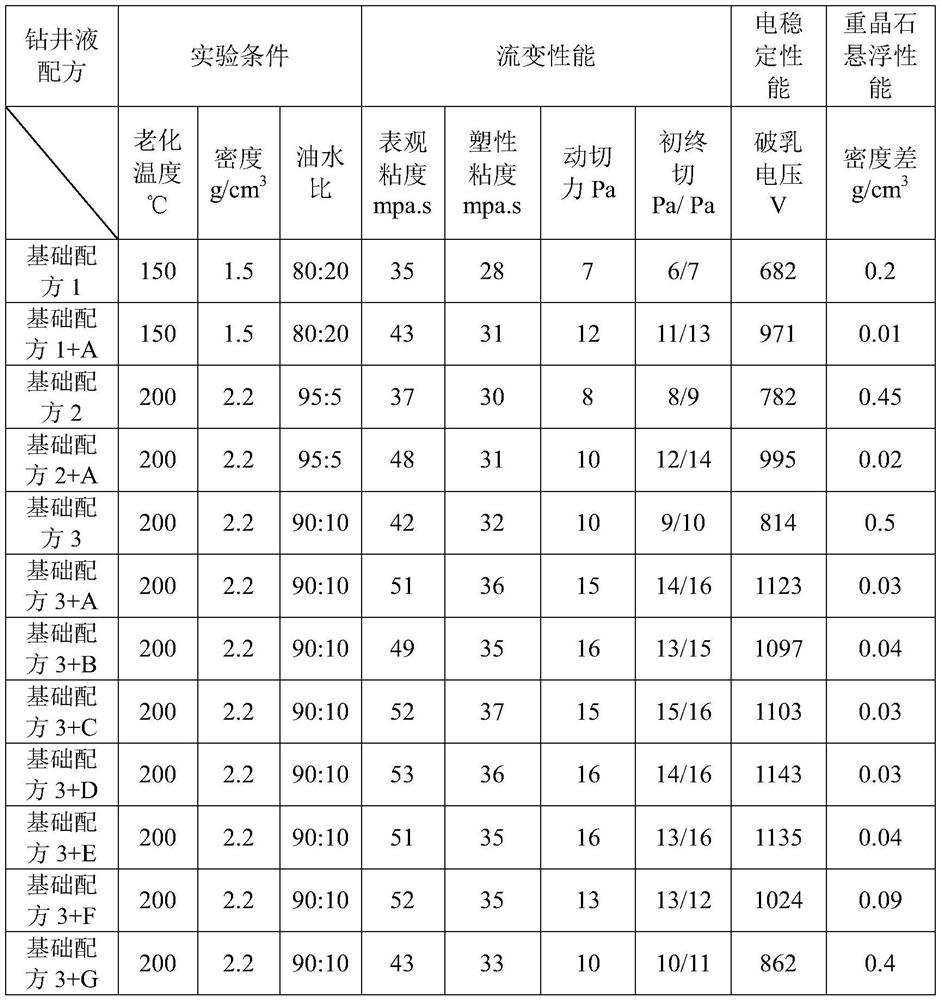

[0030] In yet another typical embodiment of the present application, an application of a cutting agent is provided, which includes using the cutting agent for an oil-based drilling fluid system, preferably the oil-based drilling fluid system is diesel oil, white oil or Any one of the gas-to-oil-based drilling fluid systems, preferably the oil-water ratio of the oil-based drilling fluid system is in the range of 80:20 to 95:5.

[0031]Applying the shear raising agent of the present application to the above-mentioned oil-based drilling fluid system is more conducive to increasing the shear force of diesel oil, white oil or gas-based oil-based drilling fluid system, thereby enhancing its barite suspension and rock-carrying ability, and compensating for organic Insufficient soil viscosification and cutting efficiency, ...

Embodiment 1

[0036] First, add 146 parts of adipic acid and 108 parts of diethylenetriamine into the reaction vessel in sequence, heat up to 165°C under constant stirring, and carry out dehydration condensation reaction for 3 hours to obtain the first post-reaction system. Then add 296 parts of oleic acid to the system after the first reaction, and continue to carry out the dehydration condensation reaction at 165°C for 3h. After the reaction is completed, cool down to 120°C, add 150 parts of 3# white oil and 30 parts of propylene carbonate, and stir evenly. The finished product of the cutting agent is obtained after discharging, which is recorded as the cutting agent A.

Embodiment 2

[0038] Firstly, 120 parts of adipic acid and 80 parts of diethylenetriamine were sequentially added into the reaction vessel, heated to 165°C under constant stirring, and dehydration condensation reaction was carried out for 3 hours to obtain the first post-reaction system. Then add 250 parts of oleic acid to the system after the first reaction, and continue to carry out the dehydration condensation reaction at 165°C for 3h. After the reaction is completed, cool down to 120°C, add 100 parts of 3# white oil and 30 parts of propylene carbonate, and stir evenly. The finished product of the cutting agent is obtained after discharging, which is recorded as the cutting agent B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com