Ultrasonic preparation method of nano metal oxide

A nano-metal and oxide technology, which is applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of inapplicability to large-scale commercial production and low product yield, and achieve low preparation cost, product purity and high yield. The effect of high efficiency and simple experimental raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A method for ultrasonically preparing nanometer metal oxides, comprising: using ultrasonic waves to treat a mixture including simple metal substances and acid solutions.

[0046] The nano metal oxide prepared by the present invention refers to a metal oxide with at least one dimension in the range of nanometer size (nanosize refers to the length dimension of ≤100nm) in three-dimensional space, which can be zero-dimensional, one-dimensional or two-dimensional nanometer Material. Zero-dimensional nanomaterials refer to three-dimensional nanoscale materials, such as nanoparticles, etc.; one-dimensional nanomaterials refer to two-dimensional nanoscale materials, such as nanowires, nanorods, nanotubes, etc.; two-dimensional nanomaterials refer to One dimension is in the nanoscale range, such as nanosheets, nanofilms, etc.

[0047] Ultrasonic treatment, that is, placing the mixture including metal element and acid solution in an ultrasonic instrument for ultrasonic treatment...

Embodiment 1

[0061] Measure 15 mL of 0.5 mol / L dilute nitric acid solution into a glass vial, add 1 mmol (65.38 mg) nano-Zn powder into it, and place the glass vial in an ultrasonic two-dimensional material stripper (Scientz-CHF-5A, Xinzhi, China) for Ultrasonic treatment, the frequency of ultrasonic treatment is 40KHz, and the power is adjusted to 360W; Under the condition of stirring, ultrasonic treatment is performed for 2 hours; after ultrasonic treatment, it is naturally cooled to room temperature, filtered, and the obtained solution is preserved and recycled to reduce reagent consumption, and the obtained white powder is used Wash with 75v / v% ethanol solution for 3 times, and finally dry at 80°C for 12h to obtain ZnO nanosheet material. After weighing, the obtained ZnO nanosheets had a mass of 75.3 mg.

Embodiment 2

[0063] Measure 30L of 0.8mol / L HCl solution in a wide-mouthed glass bottle, add 20mmol (1307.6g) nano-Zn powder into it, and place the wide-mouthed glass bottle in an ultrasonic two-dimensional material stripper (Scientz-CHF-5A, Xinzhi, China) Ultrasonic treatment was carried out, the ultrasonic treatment frequency was 40KHz, and the power was adjusted to 720W; under stirring conditions, ultrasonic treatment was performed for 3.5h; after ultrasonic treatment, it was naturally cooled to room temperature, filtered, and the obtained solution was preserved and recycled to reduce reagent consumption and obtain white The powder was washed three times with 80v / v% ethanol solution, and finally dried at 75° C. for 12 hours to obtain ZnO nanosheet material. After weighing, the obtained ZnO nanosheets had a mass of 1494g.

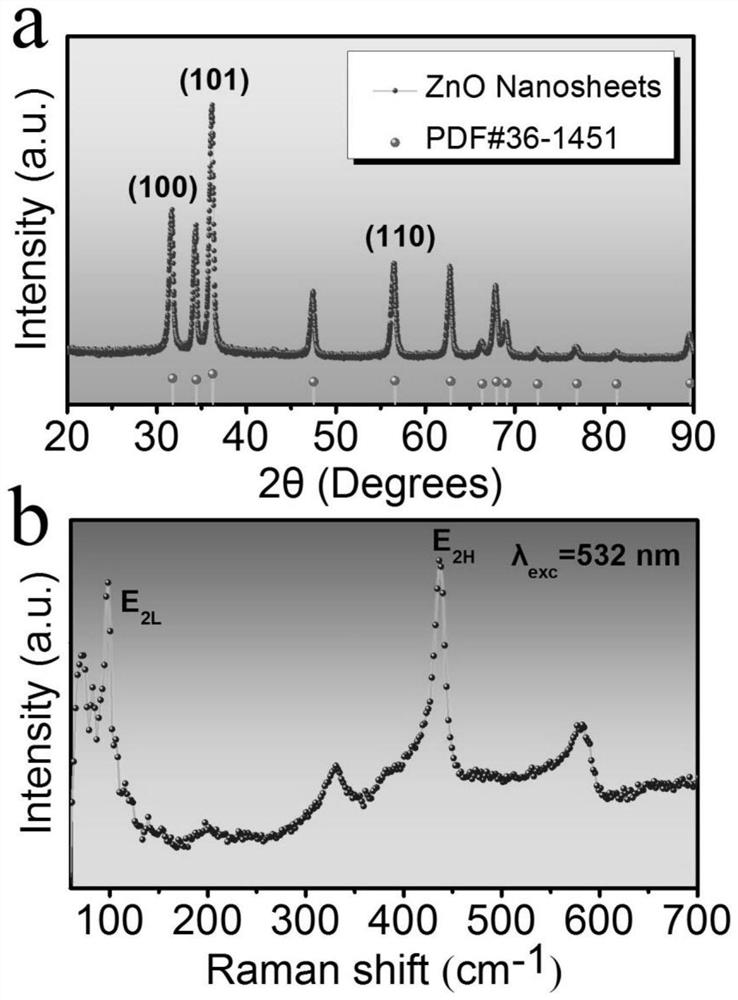

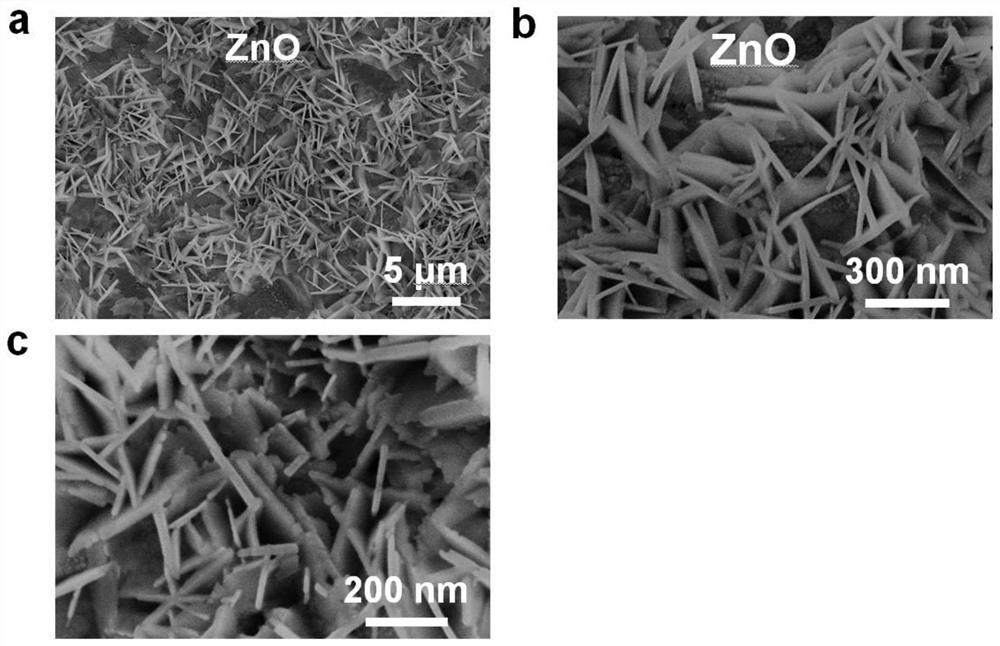

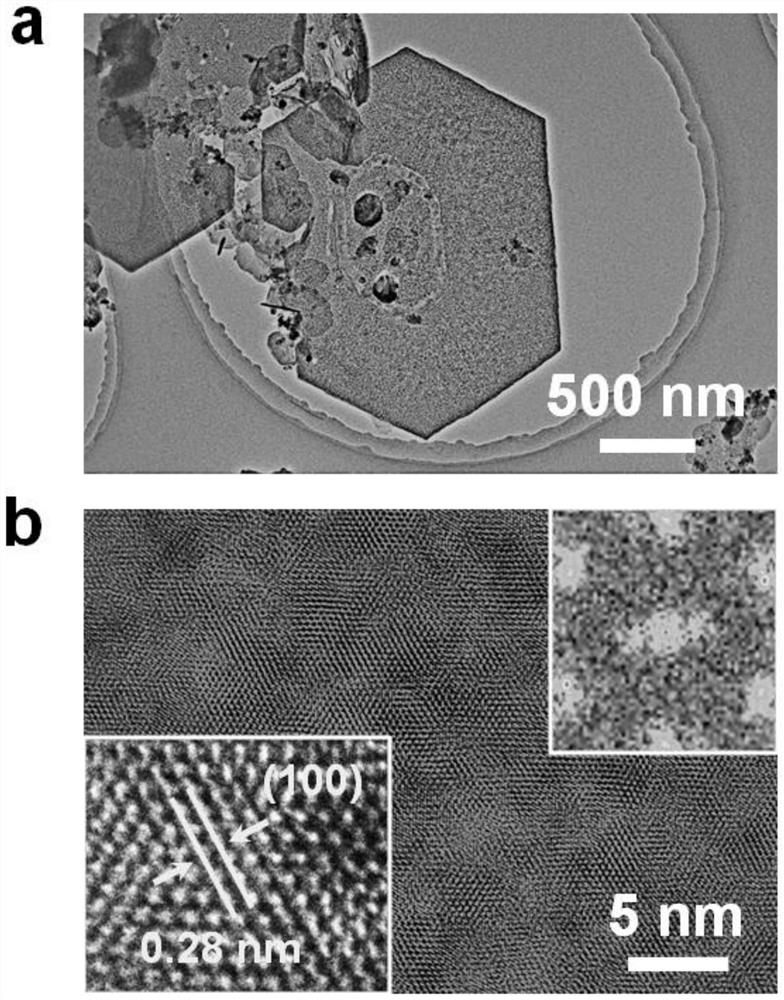

[0064] figure 1 (a) is the X-ray diffraction pattern (XRD) of the ZnO nanosheet obtained in Example 2. The XRD spectrum shows that the ZnO nanosheets obtained by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com