Preparing method of supported type gold-platinum alloy nanocluster material

A gold-platinum alloy and nano-cluster technology, which is applied in the field of preparation of supported gold-platinum alloy nano-cluster materials, can solve the problems of poor dispersion of supported catalysts, affecting catalytic performance, unfavorable material applications, etc., and achieve batch production. Controlled production, good crystallinity and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

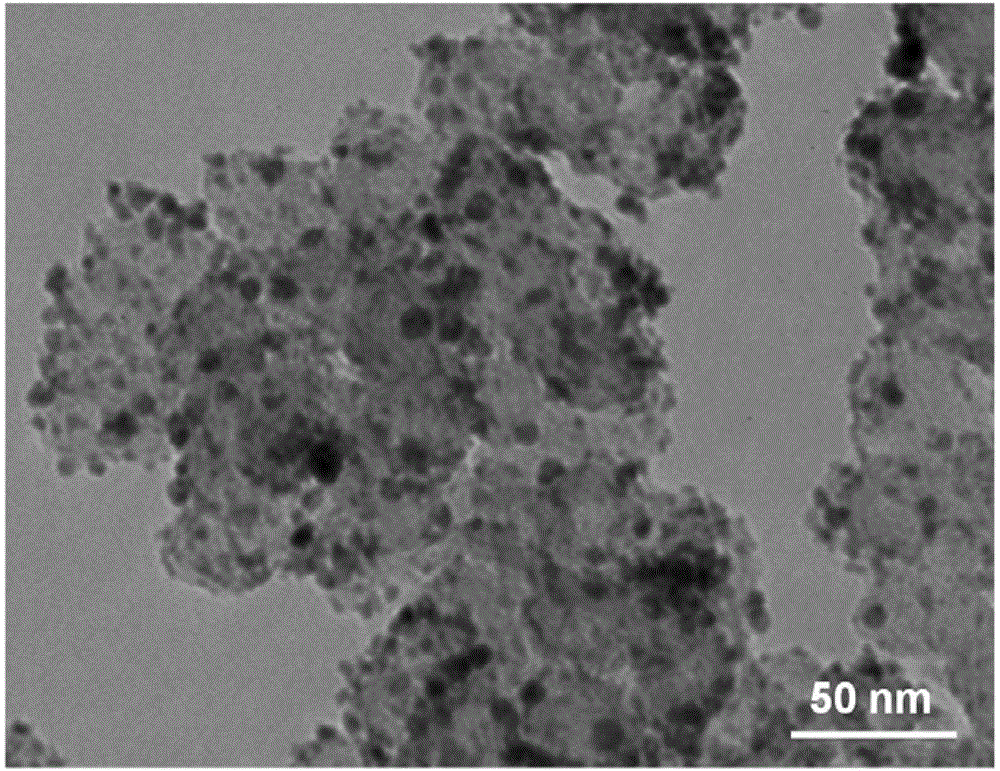

[0029] Example 1 Preparation of carbon black-supported gold-platinum alloy nanocluster material

[0030] 1) Preparation of platinum and gold electrodes

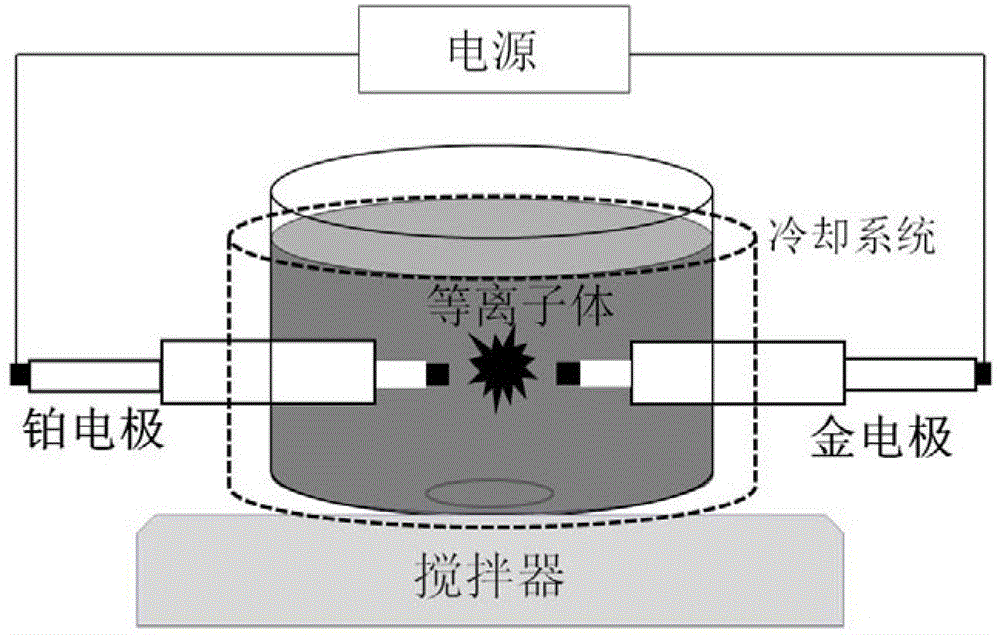

[0031] Take a platinum wire and a gold wire with a diameter of 1mm and a length of 10mm, put the two metal wires on an alumina insulating tube (inner diameter 1mm, outer diameter 1.5mm), and then fix them in a Teflon tube (inner diameter 1.5mm), that is Platinum and gold reaction electrodes are obtained. Install the above-mentioned platinum and gold reaction electrodes on the glass container through the hole on the container wall in a horizontally opposite position. The distance between the platinum and gold electrodes is fixed at 0.3mm, and the angle between the electrodes is fixed at 180°. The power supply (model MPS-06K-01C, Kurita Manufacturing Co., Ltd., Japan) forms a discharge circuit. Such as figure 1 Place the glass container in a room temperature water bath as indicated.

[0032] 2) Preparation of carbon black s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com