Preparation method of matrix ceramic powder for additive manufacturing of Longquan celadon

A ceramic powder and additive manufacturing technology, which is applied in the field of additive manufacturing, can solve the problems of complex and lengthy manufacturing process, low yield and reliability, and application lag, and meet the requirements of simple experimental equipment, good flow characteristics, and solution method complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

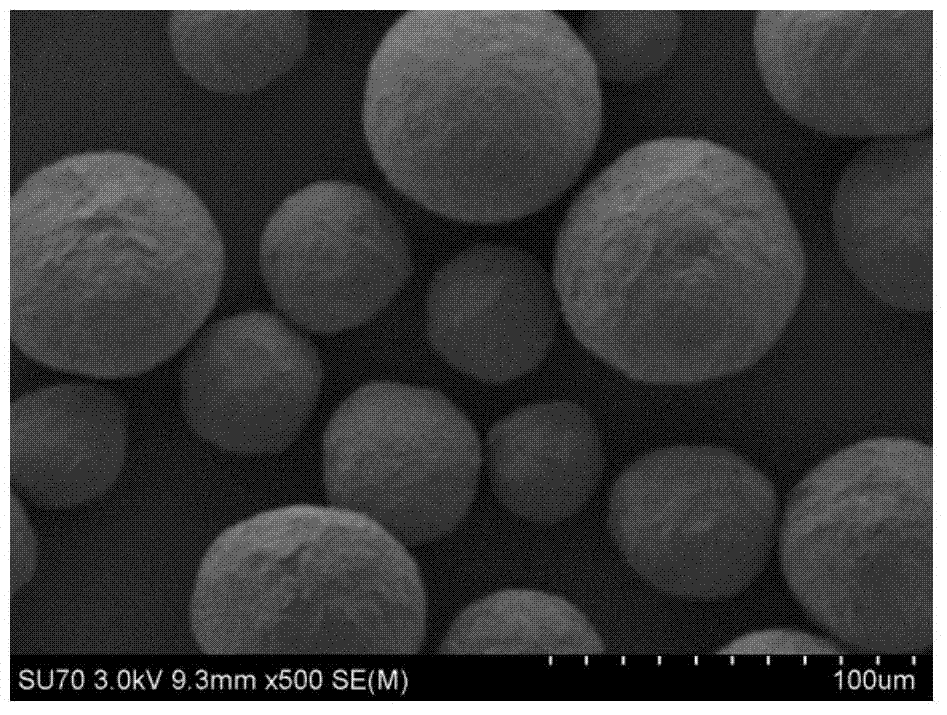

Image

Examples

Embodiment 1

[0028] Embodiment 1, a kind of preparation method of additive manufacturing Longquan celadon body ceramic powder, carries out following steps successively:

[0029] (1) Use deionized water as the dispersion medium, 50% polyvinyl alcohol solution as the binder, 20% polyethylene glycol solution as the dispersant, and n-butanol as the defoamer agent, add Ge kiln powder for ball milling and mixing for 4-8 hours (use Φ5mm silicon carbide sand as ball milling medium);

[0030] Polyethylene glycol 2000 is selected for polyethylene glycol; high-viscosity polyvinyl alcohol (average molecular weight is 180,000 to 200,000) is selected for polyvinyl alcohol.

[0031] The mass ratio of Ge kiln powder and deionized water is 50%; the mass ratio of polyvinyl alcohol solution and Ge kiln powder is 1%; the mass ratio of polyethylene glycol solution and Ge kiln powder is 0.3%; The mass ratio of alcohol to Ge Kiln powder is 0.5%.

[0032] Ge kiln powder is composed of the following components b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com