Spray cooling device for condensation of phase-change material assisted gas-phase working medium

A phase change material, spray cooling technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve problems such as heat dissipation deterioration, reduce back pressure, enhance heat transfer effect, and enhance utilization The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

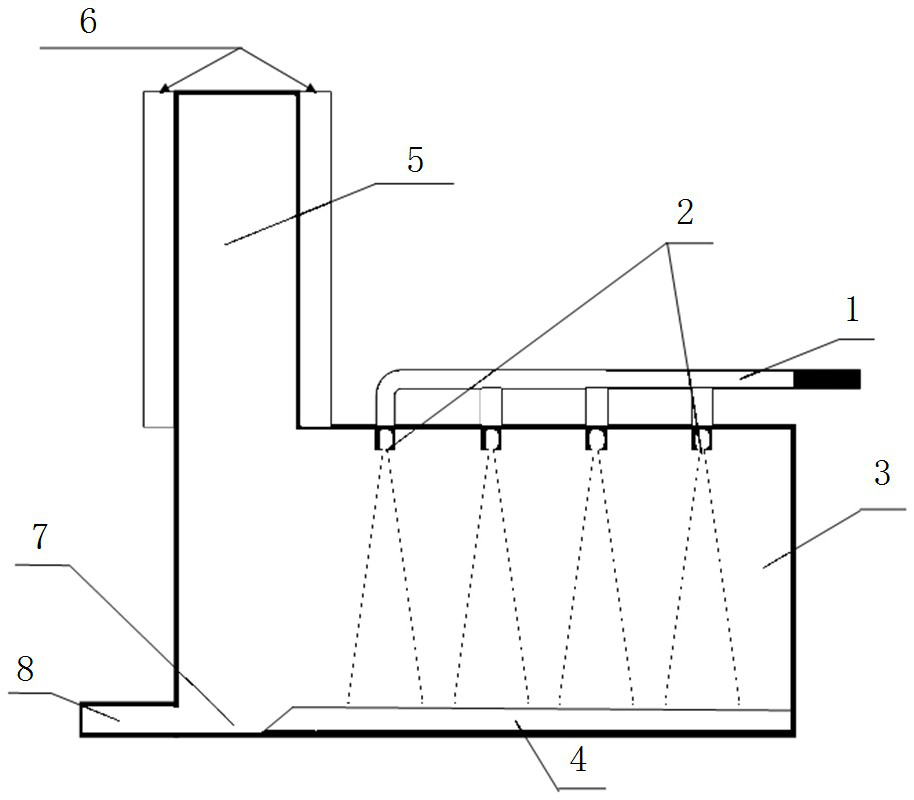

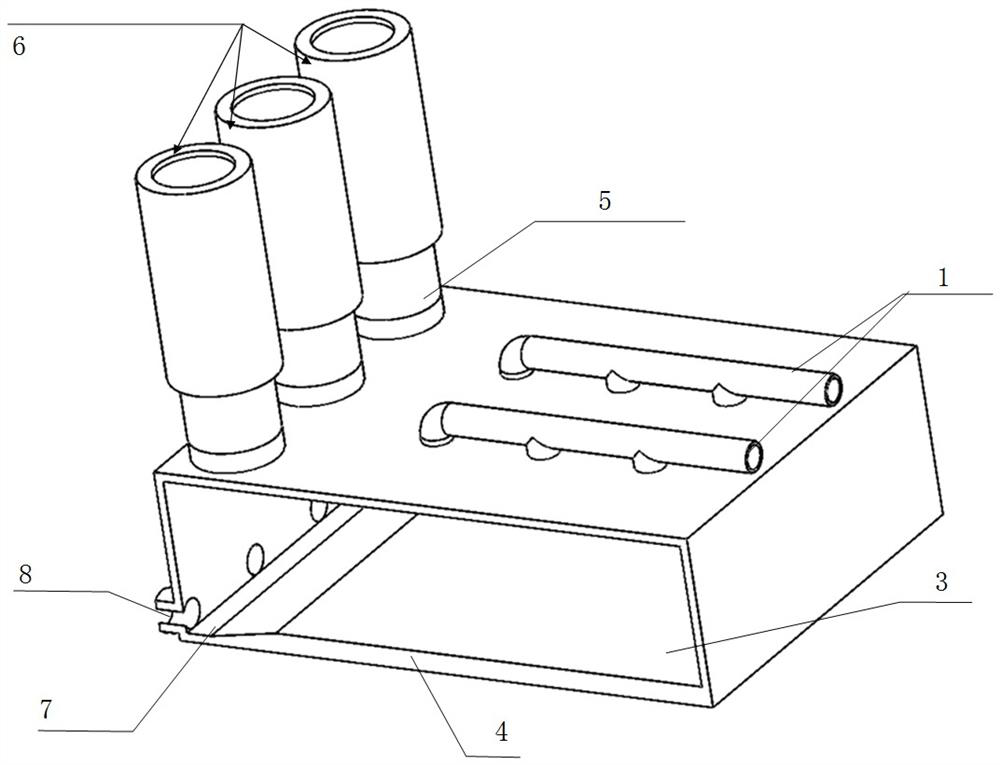

[0026] See figure 2 , A condensed spray cooling apparatus a phase change material includes a spray assisted vapor working chamber 3, the outer top of the spray chamber 3 is mounted on the two rows of inlet tube 1 through the branch pipes are each equipped with Bouin 1, two rows of nozzle inlet pipe array 2, the spray nozzle array 2 located at the top of cavity 3. 4 is attached to the thermal diffusion plate, and the heat diffusion plate 4 adjacent to the floor at the edge of the spray chamber 3 is provided with a concave shape as a sump on the bottom plate 7 of the spraying chamber 3, a spray chamber 7 side 3 side of the sump Bouin walls are provided with three or more liquid discharge pipe 8.

[0027] See figure 2 , 7 above the top of the spray sump chamber 3 are mounted side by side three cylindrical tubular condensation chamber 5. See figure 1 , The upper end of each condensation chamber 5 of the cylindrical tube is closed, the lower end of the spray chamber is connected by a s...

Embodiment 2

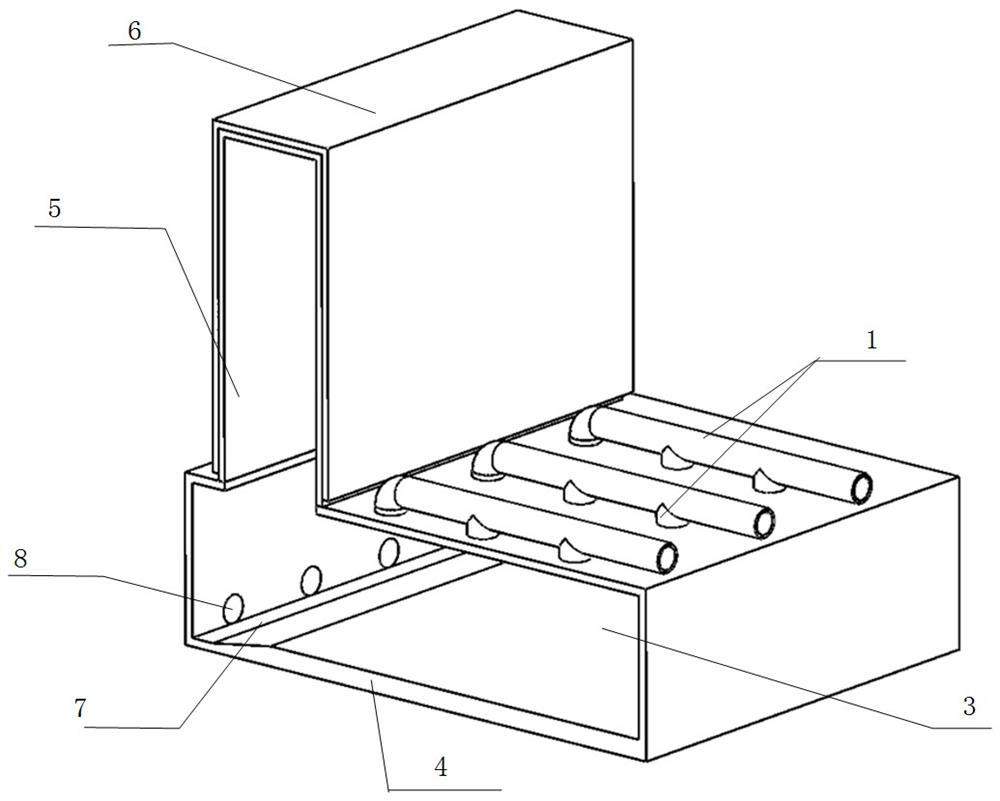

[0033] See image 3 , Condensation chamber 5 cuboidal housing, the housing top surface and four side surfaces are wrapped with a phase change material 6. The outer top of the spray chamber 1 3 is mounted on the branch pipe are respectively provided with a nozzle array of three rows of Bouin liquid inlet pipe 1, three rows of inlet tube 2, the spray nozzle array 2 located at the top of cavity 3. Other structures in Example 1.

[0034] Spray chamber cuboidal metal shell 3 has a size of 400 × 200 × 100 (mm), wall thickness is 5mm, the top nozzle array 3 to a spray chamber 2 8 × 3 arrangement, the spacing between adjacent nozzles is 30mm.

[0035] 5 material in the condensation chamber 2 This example aluminum alloy, box dimensions: height 150mm, length and width are 350mm, 80mm, a wall thickness of 5mm. 3 is connected to the interface on top of the rectangular spray chamber. The thickness of the outer surface of the phase change material wrapped condensation chamber 5 is 5mm, to provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com