Device and process for disassembling lithium batteries and recycling metal ions

A metal ion and lithium battery technology, which is applied in the field of devices for dismantling and recovering metal ions of lithium batteries, can solve the problems of reducing the recovery efficiency of the device, reducing the recovery rate of metal ions, increasing the difficulty and inconvenience of finishing work for operators, etc. Improve the effectiveness of metal ion recovery, increase functionality and practicality, and facilitate the effect of scrap recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

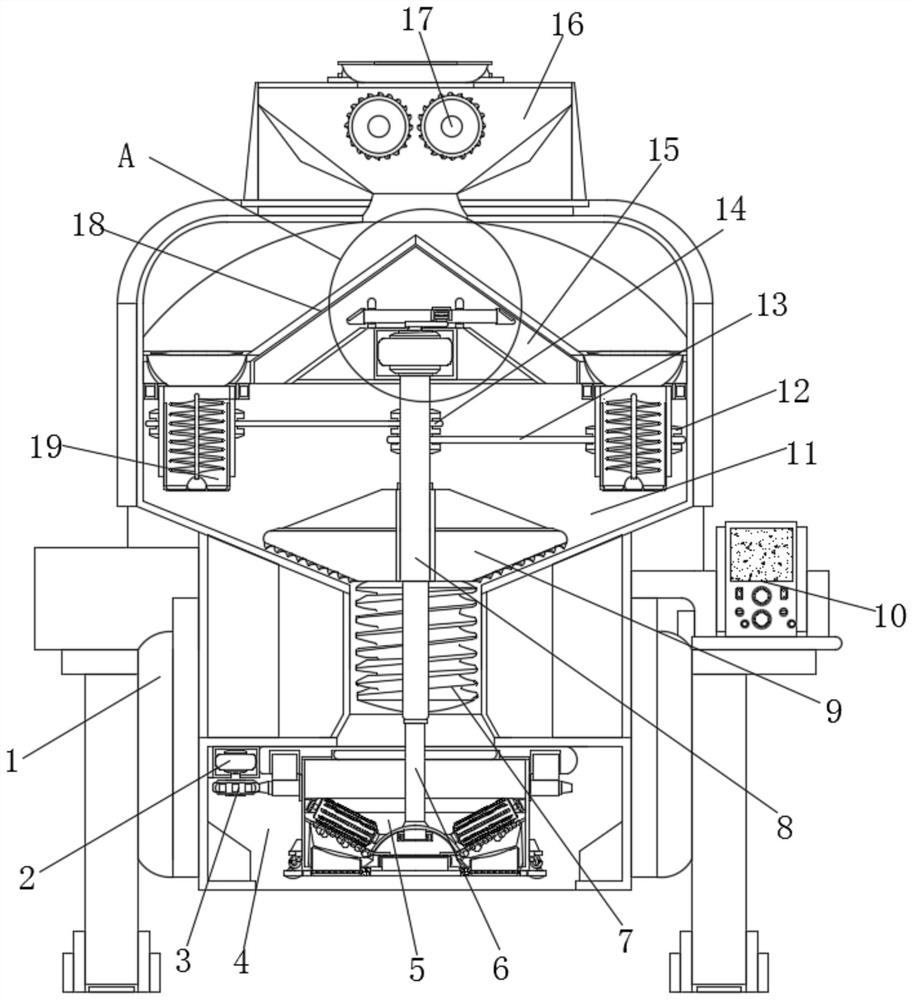

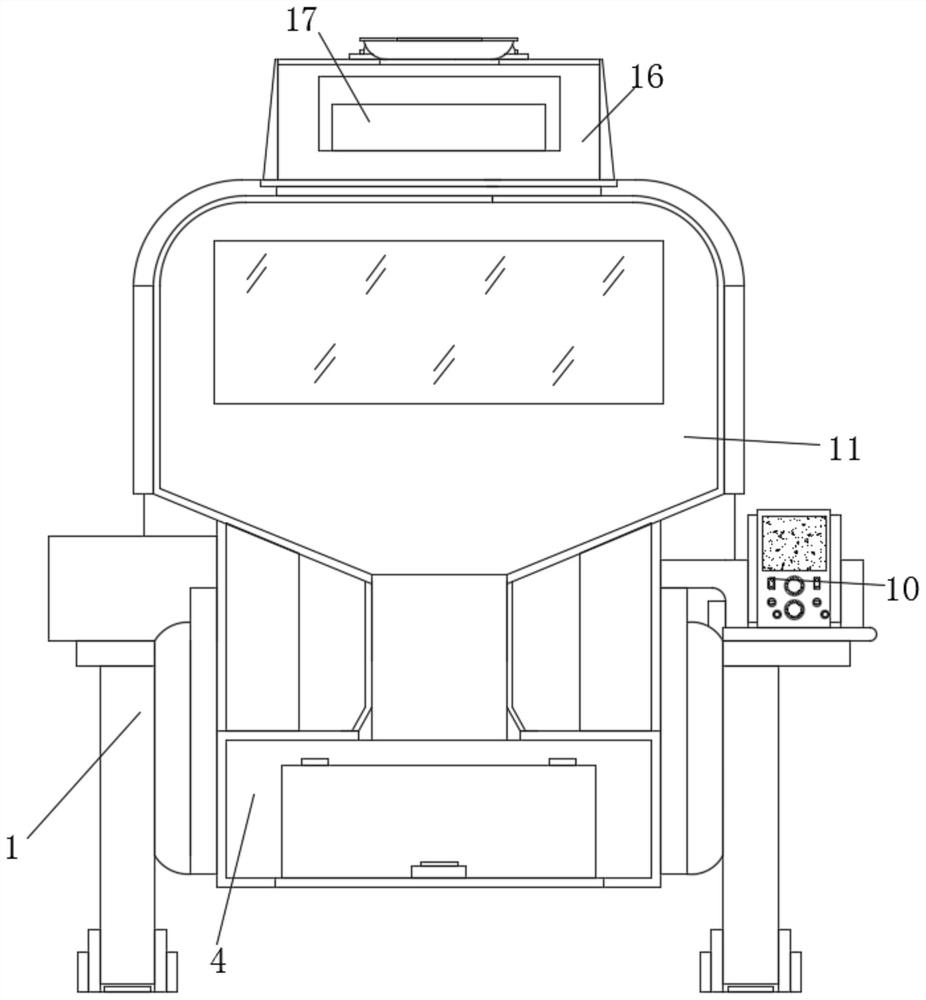

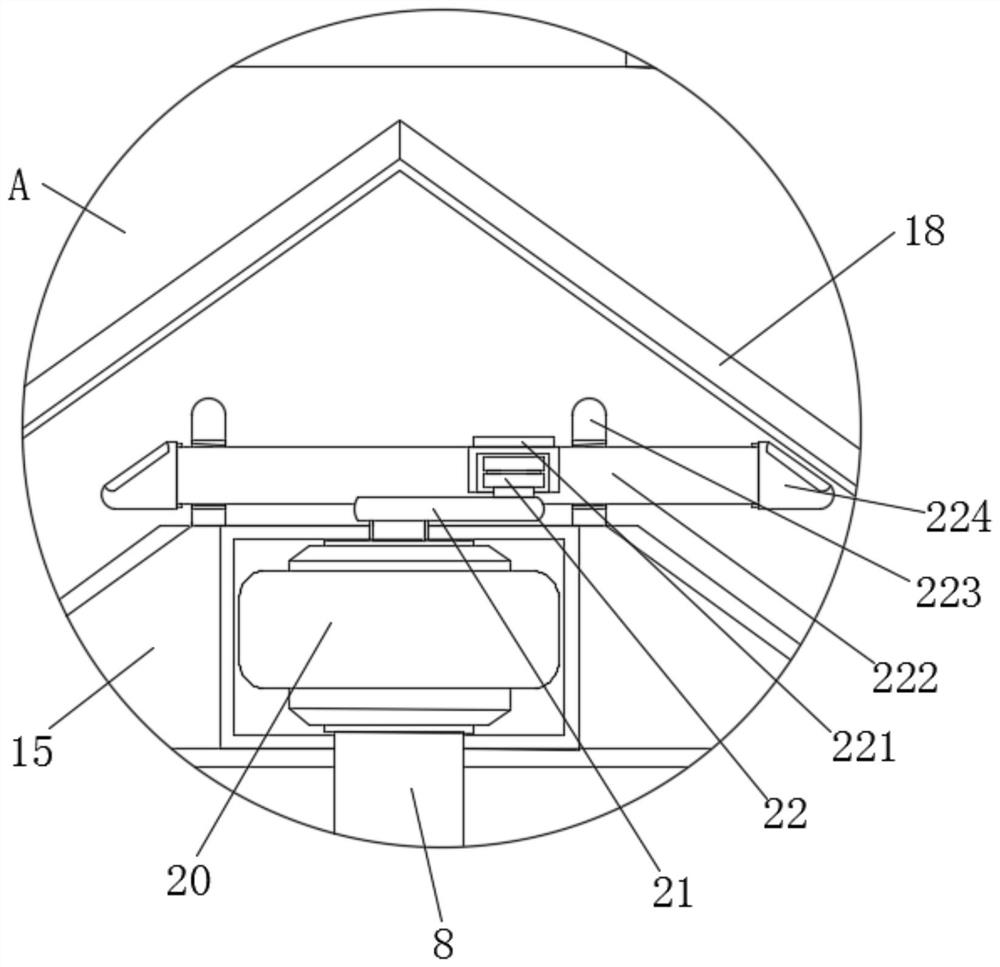

[0047] Example 1, such as figure 1 and Figure 6 As shown, when the lithium battery enters the inside of the material guide tube 19 through two sets of inclined material guide frames 18, the second pulley 14 can be driven to rotate by the start of the biaxial motor 20, and the rotation of the second pulley 14 and the belt 13 The linkage cooperation with the first pulley 12 forces the two sets of first pulleys 12 to drive the feed pipe 19 to rotate under the cooperation of the bearings, so that the lithium battery entering the inside of the feed pipe 19 is stirred and pulverized under the cooperation of the spiral stirring rod, and With the cooperation of the hemispherical guide seat, the lithium battery is evenly discharged from the bottom of the material guide tube 19, which improves the crushing accuracy of the lithium battery and the recovery effect of subsequent metal ions.

Embodiment 2

[0048] Example 2, such as figure 1 and Figure 8 As shown, after the lithium battery is rolled by two groups of rolling rollers 604, it penetrates into the filter mesh groove 601 from the filter mesh plate 602. At this time, the lithium battery in the filter mesh groove 601 is subjected to secondary Filtration promotes the metal ions of the lithium battery to be separated from the lithium battery very well. At this time, the connection and fixation of the elastic hook and the hanging ring can be canceled, and the filter mesh groove 601 can be canceled as a whole by the suction and fixation of the magnetic suction ring and the magnetic suction groove. The filter mesh tank 601 is taken out separately, and the waste materials received by the filter mesh groove 601 are recovered and processed, so as to increase the operability and convenience of the recycling process after the lithium battery is separated.

[0049] To sum up: the device uses the secondary crushing function and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com