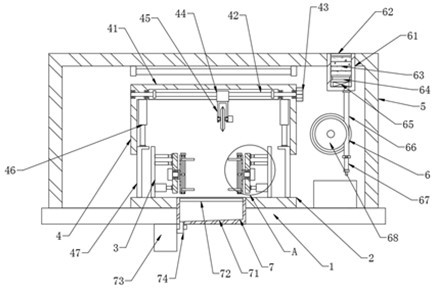

Vanadium battery pack disassembly evaluation test bench

A battery pack and test bench technology, applied in the field of alum batteries, can solve the problems of time-consuming and labor-intensive shells, staff injuries, electrolyte leakage, etc., and achieve the effect of convenient all-round cutting and high flexibility of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

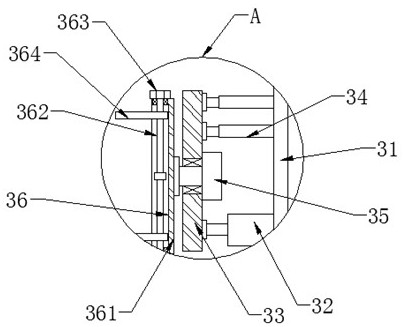

[0026] As an embodiment, the clamping mechanism 3 includes a first fixed plate 31 fixed on both ends of the top of the first mounting plate 2, a first hydraulic cylinder 32 is installed on the side of the first fixed plate 31, and the piston of the first hydraulic cylinder 32 The side of bar is equipped with second fixed plate 33 and guide mechanism 34 is installed between the second fixed plate 33 and first fixed plate 31, and the side of second fixed plate 33 is equipped with first motor 35, the output shaft of first motor 35 A splint mechanism 36 passes through the second fixing plate 33 and is connected to it.

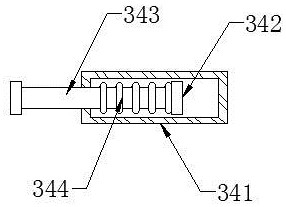

[0027] As an embodiment, the guide mechanism 34 includes a sleeve 341 fixed on the side of the first fixing plate 31, the inside of the sleeve 341 is slidably connected with a first slider 342, and a connecting rod 343 is installed on the side of the first slider 342, The connecting rod 343 passes through the sleeve 341 and is connected to the second fixing plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com