Preparation method of a high-strength, solvent-resistant, rapidly disassembled and recyclable epoxy fiber composite material

A composite material and epoxy fiber technology, applied in the field of polymer materials, can solve the problems of poor strength, late start, difficulty in fast disassembly and efficient recycling, and achieve high strength and solvent resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

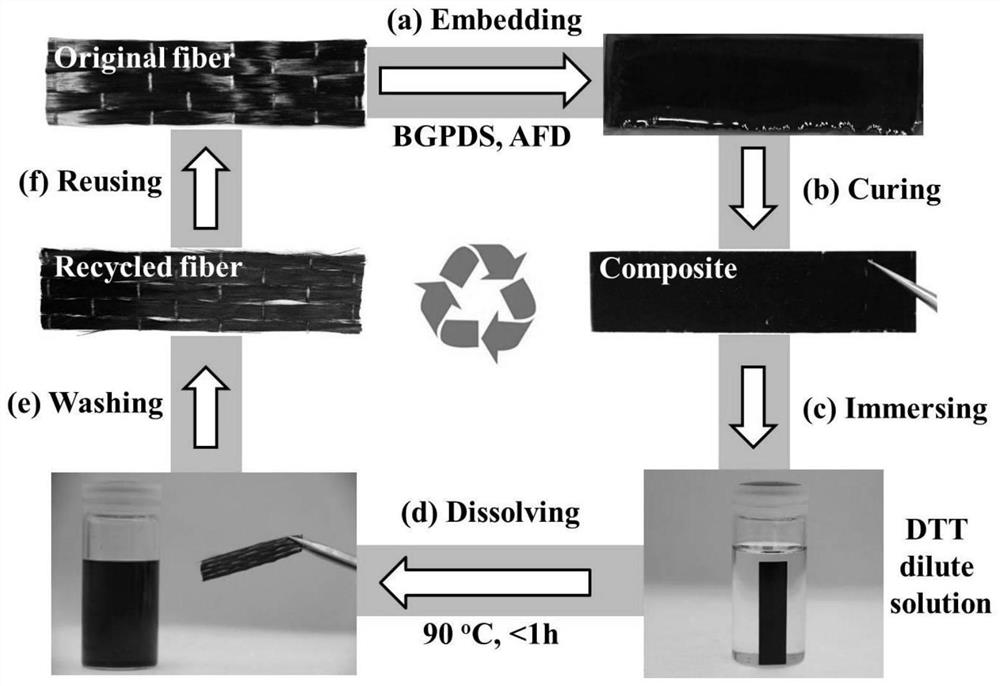

Embodiment 1

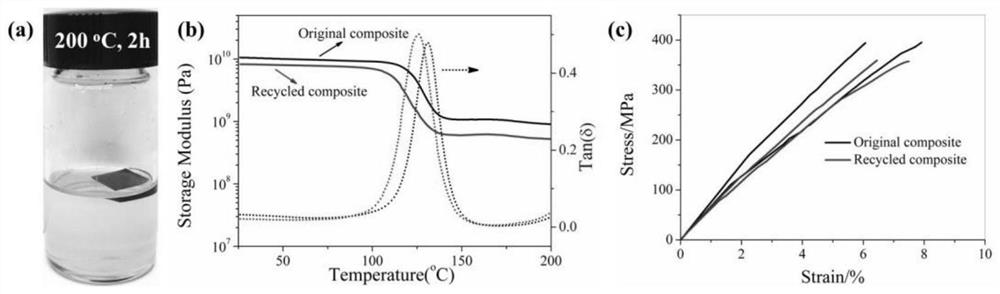

[0017] The epoxy monomer (BGPDS) with aromatic disulfide bonds and the epoxy curing agent (AFD) with aromatic disulfide bonds are used to compound with carbon fiber materials, and cured at 160 degrees for 3 hours to obtain high aromatic disulfide bonds. Strong solvent resistant fast dismantling epoxy carbon fiber composite. The specific preparation process is as follows. Dithiodiphenyl diglycidyl ether is used as the epoxy monomer, dithiodiphenylamine is used as the epoxy curing agent, and three-dimensional carbon fiber cloth is used as the fiber material. After the polymer and the fiber material are fully impregnated, React at 160 degrees for 3 hours to prepare epoxy carbon fiber composites based on aromatic disulfide bonds. Subsequently, the rapid disassembly and fiber recovery of the epoxy composite was achieved by soaking in a dithiothreitol (DTT) dilute solution at room temperature or under heating conditions, as figure 1 shown. When the epoxy matrix is quickly and co...

Embodiment 2

[0019] Use epoxy monomers with aromatic disulfide bonds and epoxy curing agents with aromatic disulfide bonds to compound with glass fiber materials, and cure at 160 degrees for 3 hours to obtain high-strength, solvent-resistant and fast curing based on aromatic disulfide bonds Disassembled epoxy fiberglass composite. The specific preparation process is as follows. Dithiodiphenyl diglycidyl ether is used as the epoxy monomer, dithiodiphenylamine is used as the epoxy curing agent, and three-dimensional glass fiber cloth is used as the fiber material. After the polymer and the fiber material are fully impregnated , and reacted at 160 degrees for 3 hours to prepare epoxy-glass fiber composites based on aromatic disulfide bonds. Subsequently, the rapid disassembly and fiber recovery of the epoxy composite was achieved by immersion in a dilute solution of dithiothreitol at room temperature or under heating. When the epoxy matrix is quickly and completely dissolved in the solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com