Sodium-ion battery positive electrode material, sodium-ion battery, preparation method and electric equipment

A sodium-ion battery and positive electrode material technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of phase transition, poor cycle stability, structural deformation, etc., and achieve ideal theoretical capacity and electrochemical performance Excellent, ideal effect of cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A kind of preparation method of the positive electrode active material of the sodium ion battery that the present invention replaces by doping with aluminum, comprises the following steps:

[0053] S1. At room temperature, fully grind the corresponding proportion of metal oxide and slightly excess (3wt% to 5wt%) sodium carbonate powder in a mortar, and then use a tablet press to compress the powder into a disc;

[0054] Among them, metal oxides include NiO, Fe 2 o 3 , MnO 2 and Al 2 o 3 , MgO, ZnO, CuO, CaO, TiO 2 , V 2 o 3 and Co 2 o 3 One or more of them, the purity of the reactant is greater than 99%.

[0055] Preferably, the metal oxide is NiO, Fe 2 o 3 , MnO 2 and Al 2 o 3 .

[0056] Starting material NaTmO 2 The molar ratio of the element Na to the element Ni is 2-4, the molar ratio of the element Na to the element Fe is 2-4, and the molar ratio of the element Na to the element Mn is 2-4.

[0057] The molar ratios of the element Na to the elements...

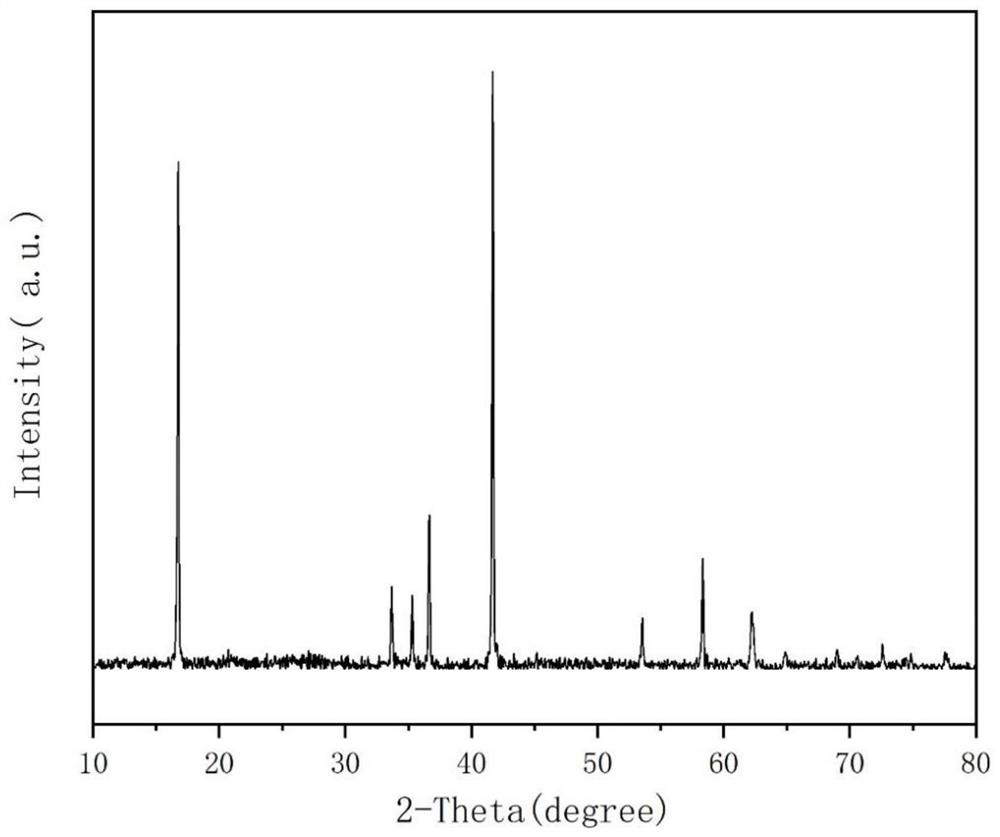

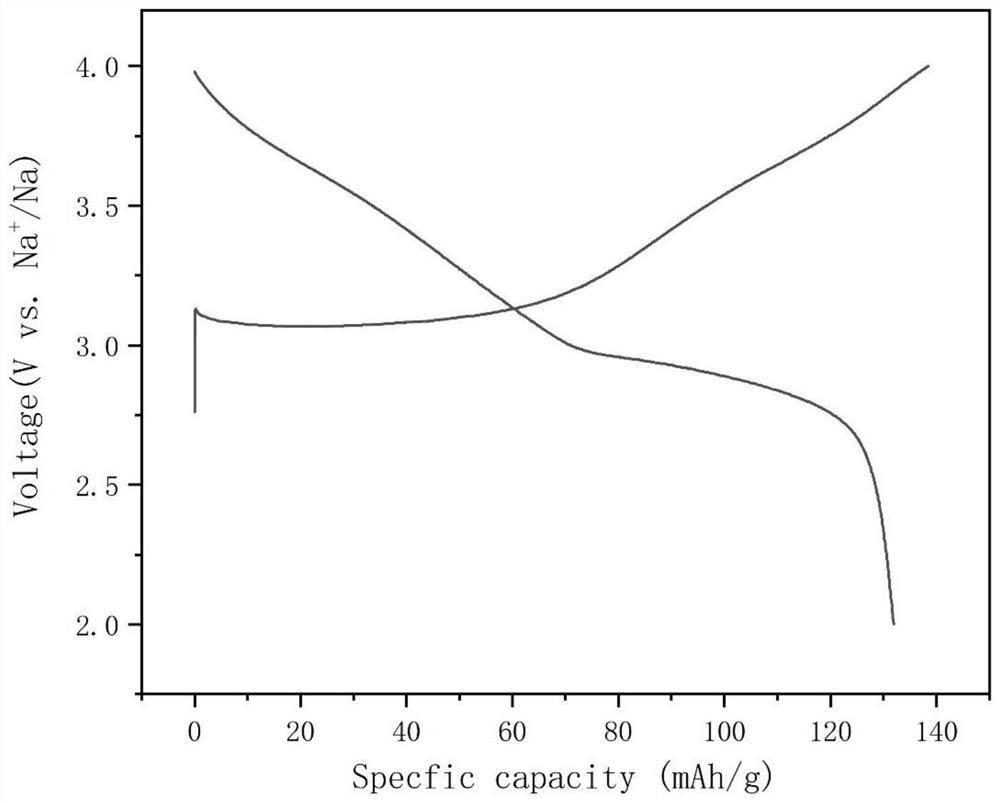

Embodiment 1

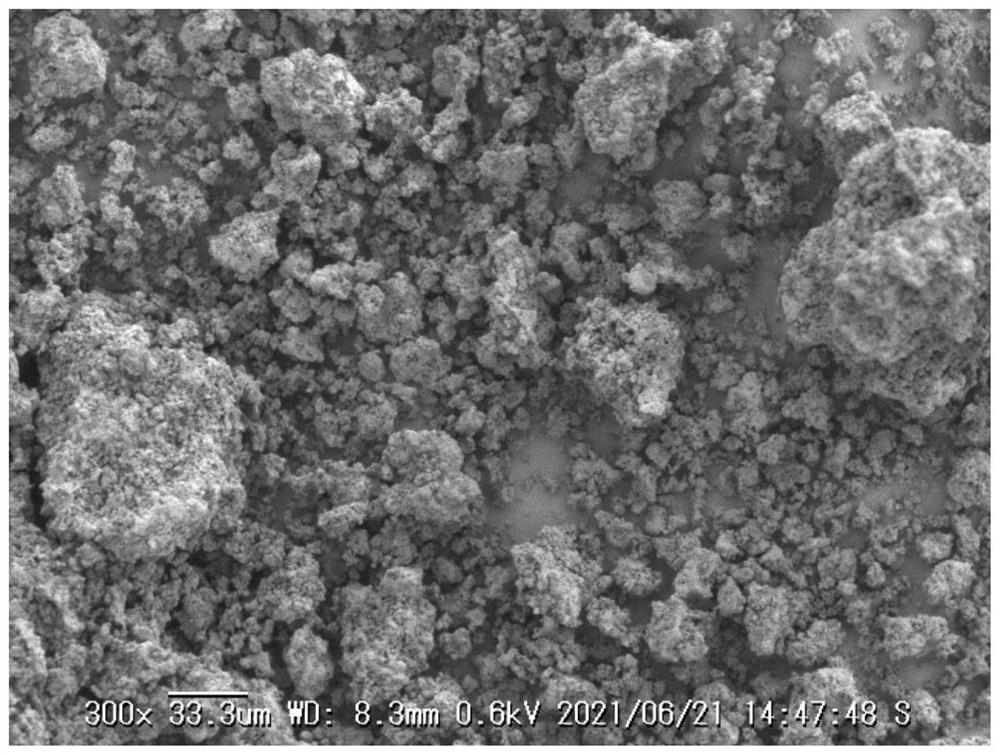

[0080] Accurately weigh Na 2 CO 3 (5% excess), NiO, Fe 2 o 3 , MnO 2 =1.05:0.5:0.5:0.5 Put the powder into a mortar and grind for 35 minutes to obtain a uniformly mixed powder. Use a powder tablet press to press the obtained powder into a disc under a pressure of 18Mpa, put it into a muffle furnace, raise the temperature to 950°C at a heating rate of 10°C / min and keep it calcined for 15h, and naturally cool it to room temperature in the furnace to obtain The positive electrode material.

[0081] The material prepared above is mixed with the conductive additive Super-P and the binder polyvinylidene fluoride (PVDF) in a mass ratio of 8:1:1, and the solvent N-methylpyrrolidone (NMP) is added into the ball mill box, Use a planetary ball mill to mill at a speed of 400r / min for 20min, apply the obtained slurry on a cleaned aluminum foil with a scraper, dry it in a vacuum oven at 80°C for 8h, and then cut it into circular pole pieces with a diameter of 10mm.

[0082] The sodium...

Embodiment 2

[0084] Accurately weigh Na 2 CO 3 (5% excess), NiO, Fe 2 o 3 、Al 2 o 3 , MnO 2 =1.05:0.5:0.485:0.015:0.5 Put the powder into a mortar and grind for 35 minutes to obtain a uniformly mixed powder. Use a powder tablet press to press the obtained powder into a disc under a pressure of 18Mpa, put it into a muffle furnace, raise the temperature to 950°C at a heating rate of 10°C / min and keep it calcined for 15h, and naturally cool it to room temperature in the furnace to obtain The positive electrode material.

[0085] The material prepared above is mixed with the conductive additive Super-P and the binder polyvinylidene fluoride (PVDF) in a mass ratio of 8:1:1, and the solvent N-methylpyrrolidone (NMP) is added into the ball mill box, Use a planetary ball mill to mill at a speed of 400r / min for 20min, apply the obtained slurry on a cleaned aluminum foil with a scraper, dry it in a vacuum oven at 80°C for 8h, and then cut it into circular pole pieces with a diameter of 10mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com