Wetting dispersant and application thereof

A technology of wetting and dispersing agent and dispersing agent, applied in the direction of pigment slurry, coating, etc., can solve the problems of easy aggregation and thickening, pigment instability, etc., to avoid aggregation, improve compatibility and stability, and avoid thickening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

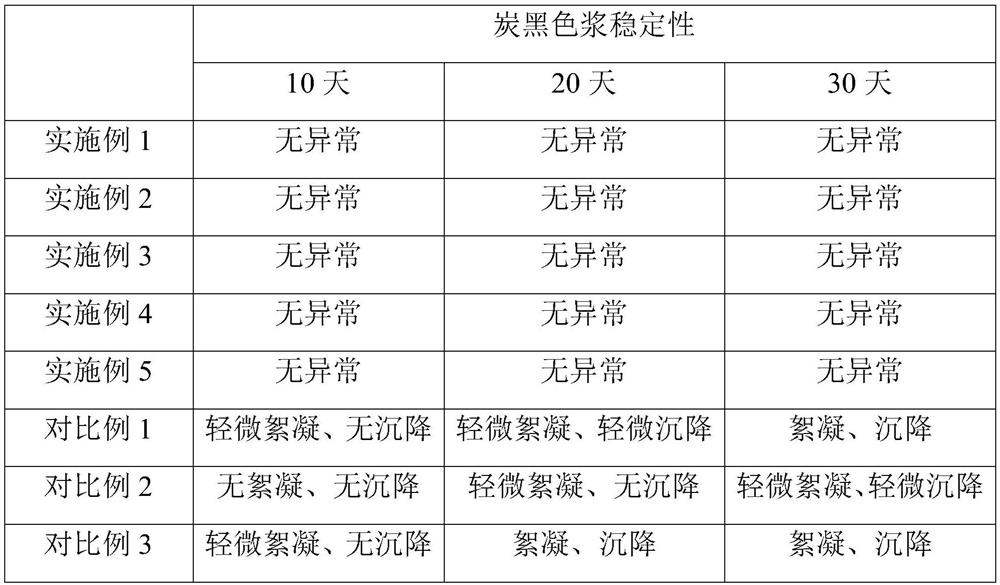

Examples

preparation example Construction

[0041] The preparation process of modified nanocellulose is as follows:

[0042] Add 5g of ground cellulose to the reaction flask, heat to 50°C, slowly add 65% sulfuric acid dropwise, stir for 3 hours, cool to room temperature, add water to terminate the reaction, centrifuge and remove the upper clear night, centrifuge 4-5 times until the upper layer appears colloid; Place the obtained colloid in a reaction flask and heat it to 80°C, add 0.001g of potassium persulfate to it to initiate, then add acrylic acid and alkenyl sulfonic acid compound and stir for 12h; Extraction under low pressure, and then extraction by rotary steaming to obtain modified nanocellulose.

[0043] When the above-mentioned alkenyl sulfonic acid compound is 2-acrylamido dodecyl sulfonic acid or 2-acrylamido-2-methyl propane sulfonic acid, the modified nanocellulose prepared is respectively denoted as CNC-1, CNC-2.

Embodiment 1

[0045] Wetting and dispersing agent A: Mix product 1, polycarboxylate dispersant and block polyether dispersant in a mass ratio of 4:1:1, add ethanol / water with a volume ratio of 1 / 4 to make the solid content 55wt %, prepared by rapid stirring;

[0046] Wetting and dispersing agent B: Add water to CNC-1 to make the solid content 40wt%;

[0047] Mix 6wt% of wetting and dispersing agent A with 40wt% of carbon black pigment, slowly add carbon black pigment in portions, stir and disperse quickly during the addition process; continue stirring for 30min after adding carbon black pigment, then add 1wt% of wetting For wet dispersant B, add water at the end to make the total mass 100%, and continue to stir until a uniform slurry is obtained; finally, ball mill in a ball mill to obtain a carbon black slurry.

Embodiment 2

[0049] Wetting and dispersing agent A: Mix product 2, polycarboxylate dispersant and block polyether dispersant in a mass ratio of 5:1:1, add ethanol / water with a volume ratio of 1 / 4 to make the solid content 55wt %, prepared by rapid stirring;

[0050] Wetting and dispersing agent B: Add water to CNC-1 to make the solid content 45wt%;

[0051] Mix 7wt% of wetting and dispersing agent A with 50wt% of carbon black pigment, slowly add carbon black pigment in portions, stir and disperse quickly during the addition process; continue stirring for 30min after adding carbon black pigment, then add 1wt% of wetting For wet dispersant B, add water at the end to make the total mass 100%, and continue to stir until a uniform slurry is obtained; finally, ball mill in a ball mill to obtain a carbon black slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com