Production method for phosphorus-containing high-magnetic-induction non-oriented silicon steel

A technology of oriented silicon steel and production method, applied in the field of metallurgy, can solve the problems such as difficulty in exerting the advantages and constraints of phosphorus element, and achieve the effects of satisfying magnetic aging requirements, reducing process costs and improving operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

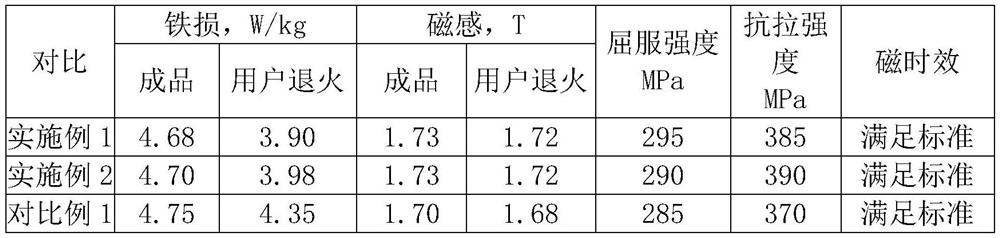

Examples

Embodiment 1

[0029] A method for producing phosphorus-containing high magnetic induction non-oriented silicon steel. The chemical composition of the steel is: C: 0.005%, Si: 0.60%, Mn: 0.25%, P: 0.11%, S: 0.0045%, Als: 0.20 %, N: 0.0015%, Cu: 0.045%, Ti+V+Nb: 0.0050%, and the rest are iron and unavoidable impurity elements. The production method comprises the following process steps:

[0030] a) Smelting and continuous casting: use converter smelting, RH vacuum refining treatment, the composition of molten steel is controlled according to the above requirements, and cast into 230mm thick slab;

[0031] b) The soaking temperature of the hot-rolled slab is 1030°C, and it is first rolled to 40mm and then enters the finish rolling unit for rolling. The finish rolling start temperature is 980°C, the finish rolling temperature is 810°C, the coiling temperature is 660°C, and the hot-rolled plate thickness is 3.0mm;

[0032] c) cold rolling to 0.50mm after pickling;

[0033] d) After cold rolli...

Embodiment 2

[0036] A production method of phosphorus-containing high magnetic induction non-oriented silicon steel, the chemical composition of the steel is: C: 0.0052%, Si: 0.58%, Mn: 0.36%, P: 0.15%, S: 0.0040%, Als: 0.25 %, N: 0.0018%, Cu: 0.070%, Ti+V+Nb: 0.0050%, and the rest are iron and unavoidable impurity elements. The production method comprises the following process steps:

[0037] a) Smelting and continuous casting: use converter smelting, RH vacuum refining treatment, the composition of molten steel is controlled according to the above requirements, and cast into 230mm thick slab;

[0038] b) The soaking temperature of the hot-rolled slab is 1020°C, and it is first rolled to 40mm and then enters the finish rolling unit for rolling. The finish rolling start temperature is 990°C, the finish rolling temperature is 820°C, the coiling temperature is 670°C, and the hot-rolled plate thickness is 3.0mm;

[0039] c) cold rolling to 0.50mm after pickling;

[0040] d) After cold roll...

Embodiment 3

[0043] A production method of phosphorus-containing high magnetic induction non-oriented silicon steel, the chemical composition of the steel is: C: 0.006%, Si: 0.25%, Mn: 0.30%, P: 0.18%, S: 0.0040%, Als: 0.15 %, N: 0.0018%, Cu: 0.035%, Ti+V+Nb: 0.0045%, and the rest are iron and unavoidable impurity elements. The production method comprises the following process steps:

[0044] a) Smelting and continuous casting: use converter smelting, RH vacuum refining treatment, the composition of molten steel is controlled according to the above requirements, and cast into 230mm thick slab;

[0045] b) The soaking temperature of the hot-rolled slab is 1000°C, and it is first rolled to 40mm and then enters the finish rolling unit for rolling. The finish rolling start temperature is 960°C, the finish rolling temperature is 780°C, the coiling temperature is 680°C, and the hot rolled plate thickness is 3.2mm;

[0046] c) cold rolling to 0.50mm after pickling;

[0047] d) After cold rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com