Method for extracting nickel from high-grade matte nickel leaching residues

A technology for leaching slag and nickel matte, which is applied in the field of metallurgy, can solve problems such as no effective methods, and achieve the effects of quick results, easy precipitation, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

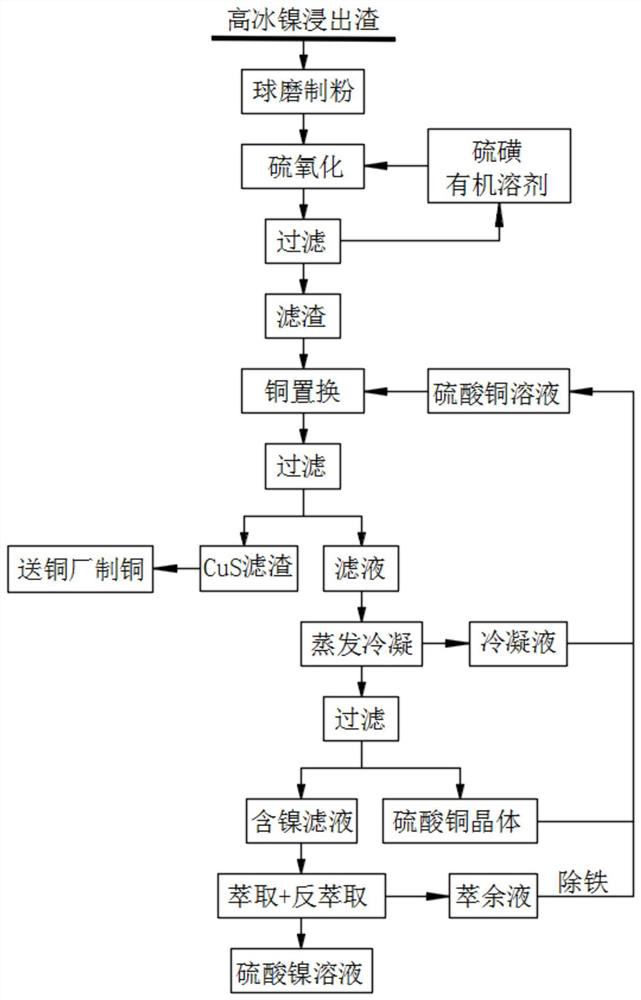

[0033] This embodiment extracts nickel and prepares nickel sulfate from high nickel matte leaching slag, high nickel matte leaching slag composition: nickel 7.38%, copper 42.3%, iron 10.9%, sulfur 23.35%, refer to figure 1 , proceed through the following steps:

[0034] (1) Raw material pretreatment: high matte leaching slag is ball milled into powder;

[0035] (2) Sulfur oxidation: Add sulfur-dissolved carbon disulfide to the powder obtained in step (1), the concentration of sulfur is 700g / L, and the solid-liquid ratio is controlled to be 1g:0.5mL, the reaction temperature is 120°C, and the reaction time for 1h;

[0036] (3) Filtration treatment: after step (2) reaction finishes, obtain filtrate and filter residue through solid-liquid separation, and filtrate is organic solvent, can recycle after supplementing sulfur;

[0037] (4) Copper replacement: Add concentration to the obtained filter residue of step (3) and be the copper sulfate solution of 4.0mol / L, and control the ...

Embodiment 2

[0043] In this embodiment, nickel is extracted from high nickel matte leaching slag and nickel sulfate is prepared. The components of high nickel matte leaching slag are: 5.58% nickel, 55.7% copper, 8.66% iron, and 20.37% sulfur, carried out through the following steps:

[0044] (1) Raw material pretreatment: high matte leaching slag is ball milled into powder;

[0045] (2) Sulfur oxidation: in the powder material gained in step (1), add in the carbon tetrachloride that dissolves sulfur, the concentration of sulfur is 10g / L, and control solid-liquid ratio is 1g: 5mL, and reaction temperature is 80 ℃, The reaction time is 5h.

[0046](3) Filtration treatment: after step (2) reaction finishes, obtain filtrate and filter residue through solid-liquid separation, and filtrate is organic solvent, can recycle after supplementing sulfur;

[0047] (4) Copper replacement: Add concentration to the obtained filter residue of step (3) and be the copper sulfate solution of 0.1mol / L, and co...

Embodiment 3

[0053] This embodiment extracts nickel from high nickel matte leaching slag and prepares nickel sulfate, high nickel matte leaching slag, composition: nickel 6.28%, copper 58.73%, iron 9.32%, sulfur 17.23%, carry out by following steps:

[0054] (1) Raw material pretreatment: high matte leaching slag is ball milled into powder;

[0055] (2) Sulfur oxidation: add decahydronaphthalene with sulfur dissolved in the powder obtained in step (1), the concentration of sulfur is 350g / L, and the solid-liquid ratio is controlled to be 1g: 2.5mL, and the reaction temperature is 100°C. The reaction time is 3h.

[0056] (3) Filtration treatment: after step (2) reaction finishes, obtain filtrate and filter residue through solid-liquid separation, and filtrate is organic solvent, can recycle after supplementing sulfur;

[0057] (4) Copper replacement: Add concentration to the obtained filter residue of step (3) and be the copper sulfate solution of 2.0mol / L, and control the solid-liquid rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com