Silicon-containing supercritical CO2 dry fracturing fluid thickening agent and preparation method thereof

A technology for dry fracturing fluid and thickener, which is applied in the field of thickener, preparation of thickener, and thickener for silicon-containing supercritical CO2 dry fracturing fluid, and can solve problems such as being unsuitable for industrial application. , to achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

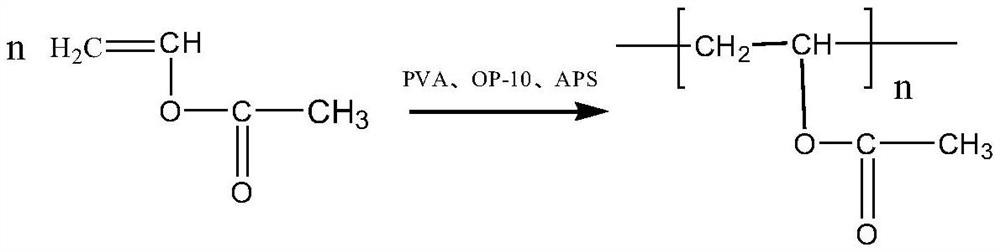

Method used

Image

Examples

Embodiment 1

[0020] Add 18g methylcyclosiloxane (DMC), 9g vinyltriethoxysilane (WD-20), 9g sodium dodecylbenzenesulfonate (SDBS) (emulsifying dispersant) to the four-necked flask successively. 3g of dodecylbenzenesulfonic acid (SDBA) (catalyst) and 60g of deionized water, stirred for 30min at a speed of 500r / min, then heated up to 80°C, started timing, and adjusted the speed to 250r / min, and reacted for 3h After that, the temperature was naturally lowered to 50°C. Adjust the pH to 7-8 with a mass fraction of 10% sodium hydroxide solution. Then adjust the rotation speed to 150r / min, then cool down to normal temperature naturally, and discharge as seed emulsion (PDMS). Add 5.5g polyvinyl alcohol (PVA) and 35g deionized water into the three-necked flask, heat up and dissolve. After cooling down to 50°C, add 5.4g octylphenol polyoxyethylene ether (OP-10), 30g vinyl acetate (VAc), 3.6g sodium dodecyl sulfate (SDS) and 60g deionized water, and adjust the speed to 500r / min, stirred for 30min,...

Embodiment 2

[0032]Add 18g methylcyclosiloxane (DMC), 9g vinyltriethoxysilane (WD-20), 9g sodium dodecylbenzene sulfonate (SDBS), 3g dodecyl Benzenesulfonic acid (SDBA) and 45g deionized water were stirred for 30min at a rotation speed of 500r / min, then the temperature was raised to 80°C, timing was started, and the rotation speed was adjusted to 250r / min, and the temperature was naturally lowered to 50°C after 3 hours of reaction. Adjust the pH to 7-8 with a mass fraction of 10% sodium hydroxide solution. Then adjust the rotating speed to be 150r / min, then naturally cool down to normal temperature, and discharge as seed emulsion. Add 4.5g polyvinyl alcohol (PVA) and 30g deionized water into the three-necked flask, and heat up to dissolve. After cooling down to 50°C, add 4g octylphenol polyoxyethylene ether (OP-10), 30g vinyl acetate (VAc), 2.7g sodium dodecyl sulfate (SDS) and 55g deionized water, and adjust the speed to 500r / min, stirred for 30 min, and transferred to the dropping fun...

Embodiment 3

[0034] Add 19g methylcyclosiloxane (DMC), 10g vinyltriethoxysilane (WD-20), 9g sodium dodecylbenzenesulfonate (SDBS), 3.5g dodecane to the four-necked flask in sequence Base benzenesulfonic acid (SDBA) and 45g deionized water, stir for 30min at a speed of 500r / min, then raise the temperature to 80°C, start timing, and adjust the speed to 250r / min, react for 3h, then naturally cool down to 50°C . Adjust the pH to 7-8 with a mass fraction of 10% sodium hydroxide solution. Then adjust the rotating speed to be 150r / min, then naturally cool down to normal temperature, and discharge as seed emulsion. Add 2.5g polyvinyl alcohol (PVA) and 20g deionized water into the three-necked flask, heat up and dissolve. After cooling down to 50°C, add 4g octylphenol polyoxyethylene ether (OP-10), 35g vinyl acetate (VAc), 2.5g sodium dodecyl sulfate (SDS) and 25g deionized water, and adjust the speed to 500r / min, stirred for 30 min, and transferred to the dropping funnel for use. Add 0.5 g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com