Copper coated antimicrobial filter material

A filter material and filter core technology, applied in filtration separation, membrane filter, dispersed particle filtration, etc., can solve the problems of insufficient killing effect of microorganisms, long time killing microorganisms, etc., and achieve a wide antimicrobial spectrum and rapid killing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1 250mg / m 2 Preparation of Copper-coated Filter Media (Sample 1-2)

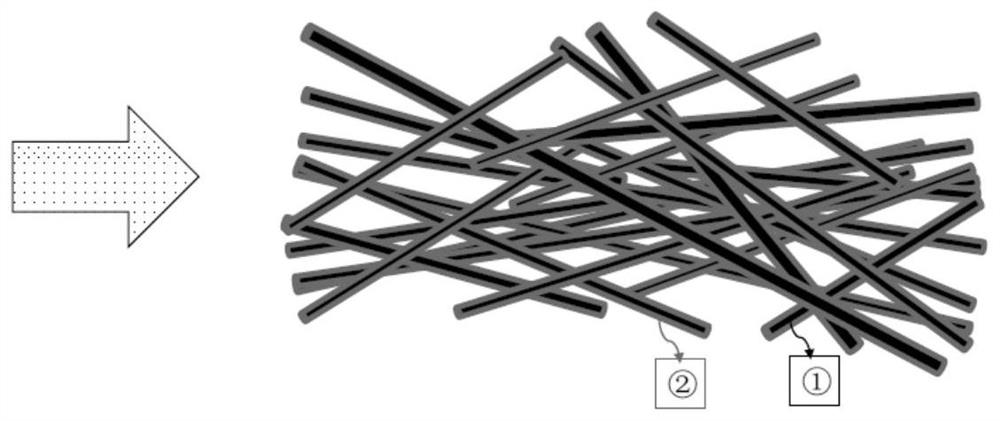

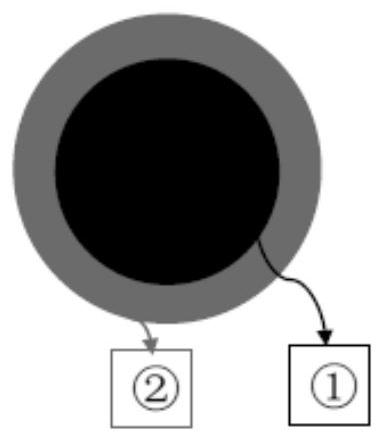

[0051] A polypropylene PP material with a filter wire diameter of 10 microns is used as the filter substrate, and the coating material is copper, and the copper is coated on the filter substrate by magnetron sputtering.

[0052] First, place the filter material substrate into the vacuum chamber, and set the transmission speed to 5m / min. In this step, the transmission speed can be adjusted due to different target loss. Subsequently, the copper target is put in place and placed in the cavity. Evacuate the vacuum chamber to 10 -4 After Pa, it is filled with 1 Pa of inert gas Ar as the carrier of gas discharge.

[0053] Set the film thickness gauge parameters of the magnetron sputtering instrument. Set the parameters of the film thickness meter to correspond to the copper equivalent of 250mg / m 2 Copper coating thickness. The instrument is turned on to carry out the coating of copper on the...

Embodiment 2

[0056] Example 2 300mg / m 2 Preparation of Copper-coated Filter Media (Sample 3-5)

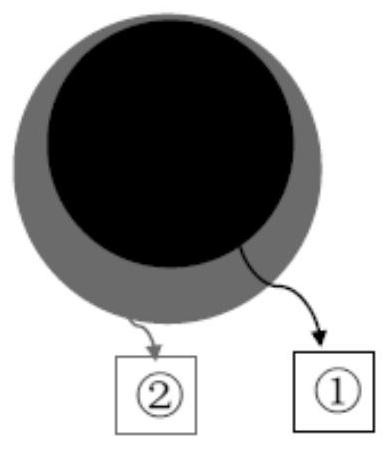

[0057] A polypropylene PP material with a filter wire diameter of 10 microns is used as the filter substrate, and the coating material is copper, and the copper is coated on the filter substrate by magnetron sputtering.

[0058] The method steps are as above, the difference is that the parameters of the film thickness meter are set to correspond to a copper equivalent of 300 mg / m 2 Copper coating thickness. The instrument was turned on for the coating of copper on the polypropylene PP substrate. Microscopic inspection to ensure uniform coating. To get coated with 300mg / m 2 Copper-coated polypropylene PP substrate (sample 3).

[0059] Using the same method, replace the filter base material with a polyester PE material with a filter wire diameter of 10 microns. Also set the parameters of the film thickness meter to correspond to the copper equivalent of 300mg / m 2 Copper coating thickness. ...

Embodiment 3

[0061] The detection-1 of the antibacterial effect of embodiment 3 sample 3-5

[0062] Test the antibacterial effect of samples 3-5. The testing unit is the Antibacterial Material Testing Center of the Institute of Physical and Chemical Technology, Chinese Academy of Sciences.

[0063] As the test microorganisms, Escherichia coli (Escherichia coli; ATCC 25922) and Staphylococcus aureus (Staphylococcus aureus; ATCC 6538) were used.

[0064] The antibacterial effect test method is as follows:

[0065] Samples for inspection are cut to a size of 18mm x 18mm.

[0066] 1 Neutralizer identification test

[0067] According to the GB15979-2002 standard of the Ministry of Health of the People's Republic of China, the bactericidal performance test must pass the following neutralizer identification test.

[0068] 1.1 Test grouping

[0069] 1) Stained bacteria sample + 5mL PBS

[0070] 2) Stained bacteria sample + 5mL neutralizer (physiological saline)

[0071] 3) Stained photos ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com