Preparation method of negative ion polyester fiber, cord fabric prepared from negative ion polyester fiber and application of negative ion polyester fiber

A polyester fiber and negative ion technology, applied in the field of negative ion polyester fiber preparation, can solve the problems of organic pollution in the car, achieve the effect of purifying the car interior environment, improving application performance, negative ion emission efficiency and high emission amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

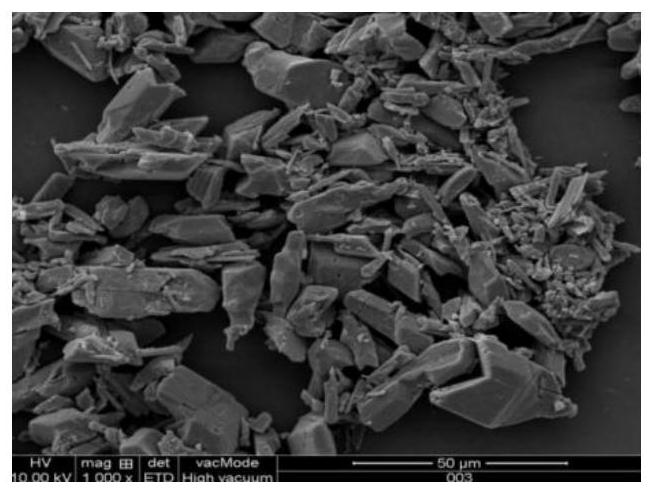

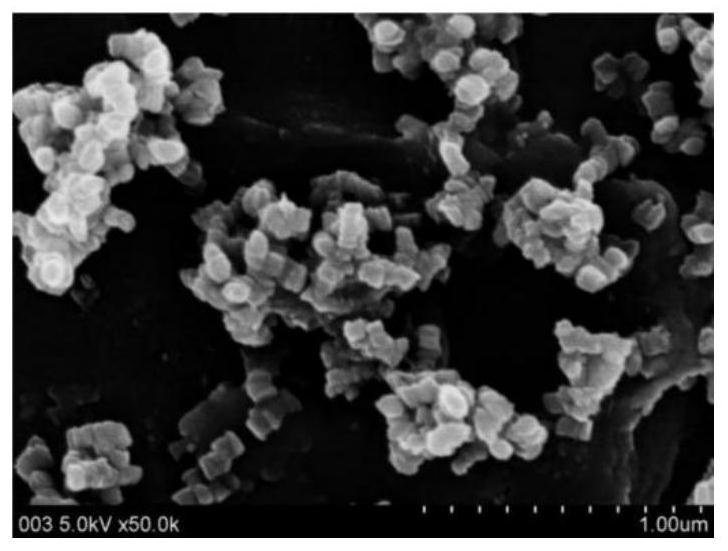

[0048] 1kg of tourmaline powder (such as figure 1 Shown) is fully dispersed in 5kg of ethanol aqueous solution, wherein the ratio of water and ethanol in the ethanol aqueous solution is 5:95, and the pH value of the system is adjusted to 3 by using oxalic acid and ammonia water. Then 0.15 kg of n-butyl titanate was added dropwise, stirred evenly and then reacted for 2 hours. Subsequently, the aqueous solution containing 0.03 kg of cerium nitrate hexahydrate was added dropwise, and the reaction was continued for 2 h. During the above reaction, continuously utilize ammonia water to adjust the pH value of the system. Then the overall temperature of the reaction system was raised to 70°C and aged for 10 hours, and the tourmaline powder was separated by suction filtration, and the tourmaline powder was filtered and cleaned, and then placed in a nitrogen atmosphere at a temperature of 800°C in a muffle Sinter in the furnace for 8h to obtain tourmaline / titanium dioxide / cerium dioxi...

Embodiment 2

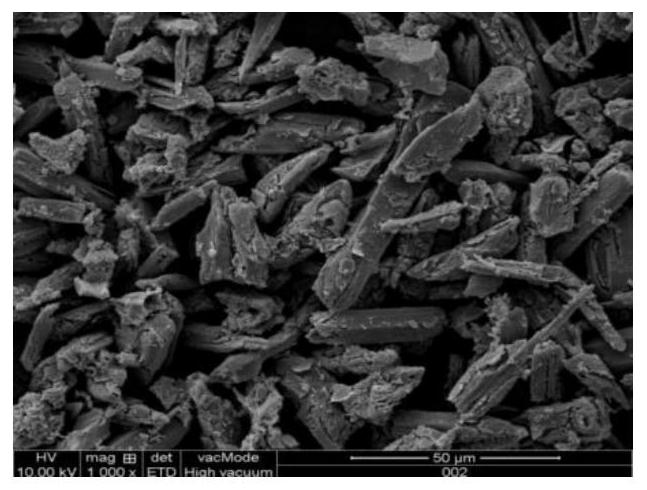

[0054] (1) Fully disperse 1 kg of dried tourmaline powder in 5 kg of ethanol aqueous solution, wherein the ratio of water and ethanol in the ethanol aqueous solution is 15:85, and use oxalic acid and ammonia water to adjust the pH value of the system to 4. Then 0.05kg of titanium tetrachloride was added dropwise, stirred evenly and reacted for 2 hours. Subsequently, an aqueous solution containing 0.01 kg of lanthanum nitrate hexahydrate and 0.01 kg of praseodymium nitrate hexahydrate was added dropwise, and the reaction was continued for 2 hours. During the above reaction, continuously utilize ammonia water to adjust the pH value of the system. Then the overall temperature of the reaction system was raised to 70°C and aged for 5 hours, and the tourmaline powder was separated by suction filtration, and the tourmaline powder was filtered and cleaned, and then placed in a helium atmosphere at a temperature of 600°C. Sinter in a furnace for 5 hours to obtain tourmaline powder dop...

Embodiment 3

[0060] (1) Fully disperse 1 kg of dried tourmaline powder in 5 kg of ethanol aqueous solution, wherein the ratio of water and ethanol in the ethanol aqueous solution is 10:90, and use oxalic acid and ammonia water to adjust the pH value of the system to 2. Then, 0.05 kg of n-butyl titanate was added dropwise, stirred evenly, and reacted for 2 hours. Subsequently, an aqueous solution containing 0.01 kg of lanthanum nitrate hexahydrate, 0.01 kg of praseodymium nitrate hexahydrate and 0.01 kg of cerium nitrate hexahydrate was added dropwise, and the reaction was continued for 2 hours. During the above-mentioned reaction, continuously utilize ammonia water to regulate the pH value of the system (PH value=2). Then the overall temperature of the reaction system was raised to 60°C and aged for 8 hours, filtered and washed with absolute ethanol to obtain tourmaline powder, and the tourmaline powder was filtered and cleaned and then placed in a nitrogen atmosphere at a temperature of 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com