Humidity-sensitive color-changing microcapsule and preparation method and application thereof

A moisture-sensitive discoloration and microcapsule technology, applied in the field of fabric printing, can solve the problems of poor effect and small application range, and achieve the effects of rich pore structure, improved sensitivity and color rendering, stable thermal performance and mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

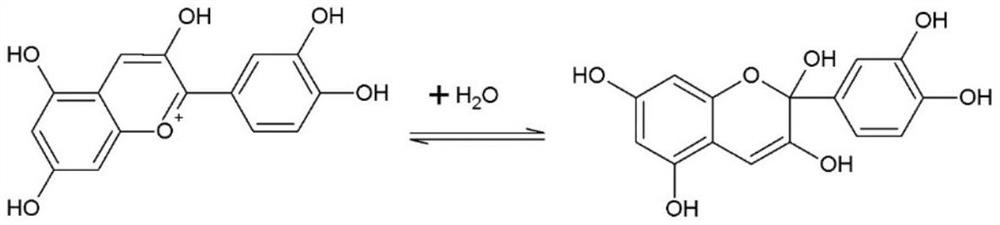

[0034] Example 1: Preparation of a moisture-sensitive color-changing microcapsule: Calculated according to the mass ratio of organic solvent: anthocyanin: emulsifier: color developer: accelerator: 10:1:0.5:0.3:0.3, add 1g to a 50ml beaker Dissolve anthocyanins, 0.5g sodium dodecylbenzenesulfonate, 0.3g sodium carbonate, and 0.3g ascorbic acid in 10g of absolute ethanol, then transfer to a three-necked flask, stir at 70°C and 150r / min for 1h to obtain anhydrous Ethanol / anthocyanin mixture. Take 10ml of the mixed solution, add 12ml of tetraethyl orthosilicate and 6ml of KH550 drop by drop, add diethanolamine to make the pH = 9, stir and react at 70°C and 150r / min for 1.5h, after completion, uniformly dispersed microcapsule suspension can be obtained liquid. The prepared microcapsule suspension was distilled off under reduced pressure to remove the solvent, and dried at 50°C for 12h to obtain anthocyanin / SiO 2 Microcapsules.

[0035] A moisture-sensitive color-changing microca...

Embodiment 2

[0037] Example 2: Calculated according to the mass ratio of organic solvent: anthocyanin: emulsifier: color developer: accelerator 20: 2: 0.6: 0.4: 0.4, add 2g anthocyanin, 0.6g Tween 80 to a 50ml beaker , 0.4g of sodium bicarbonate, and 0.4g of glycerin were dissolved in 20g of dichloromethane, then transferred to a three-necked flask, and stirred at 75°C and 300r / min for 2h to obtain a mixture of dichloromethane / anthocyanins. Take 10ml of the mixed solution, add 20ml of tetraethyl orthosilicate and 8ml of KH560 drop by drop, add triethanolamine to make the pH = 9, stir and react at 75°C and 300r / min for 2.5h, after completion, uniformly dispersed microcapsule suspension can be obtained liquid. The prepared microcapsule suspension was distilled off under reduced pressure to remove the solvent, and dried at 50°C for 12h to obtain anthocyanin / SiO 2 Microcapsules.

[0038] A moisture-sensitive color-changing microcapsule fabric printing process: weighing anthocyanin / SiO in a 50m...

Embodiment 3

[0039] Example 3: Calculated according to the mass ratio of organic solvent: anthocyanin: emulsifier: developer: accelerator: 15: 1.5: 0.55: 0.35: 0.35, add 1.5g anthocyanin and 0.55g Span to a 50ml beaker 80. Dissolve 0.35g of sodium carbonate and 0.35g of glycerin in 15g of absolute ethanol, then transfer to a three-necked flask, and stir at 75°C and 200r / min for 1.5h to obtain a mixture of absolute ethanol / anthocyanin. Take 10ml of the mixed solution and add 15ml of tetraethyl orthosilicate and 7ml of KH550 dropwise, add diethanolamine to make the pH = 9, stir at 70°C at 200r / min for 1.8h, and a uniformly dispersed microcapsule suspension can be obtained after completion. The prepared microcapsule suspension was distilled off under reduced pressure to remove the solvent, and dried at 50°C for 12h to obtain anthocyanin / SiO 2 Microcapsules.

[0040] A moisture-sensitive color-changing microcapsule fabric printing process: weighing anthocyanin / SiO in a 50ml beaker 2 Mix 3.5g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com